Emulsion microfiltration circulating system and technology

A circulation system and emulsion technology, applied in the emulsion microfiltration circulation system and process field, can solve the problems of product downgrading, work roll loss, and failure to form a filter layer, etc., to ensure quality and yield, and eliminate loss And the effect of replacing and reducing the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

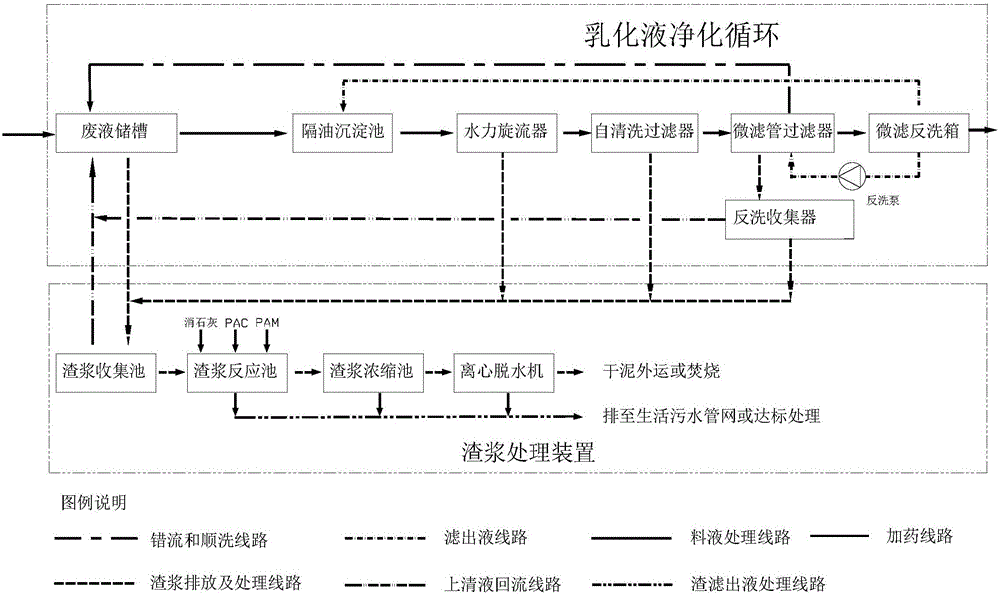

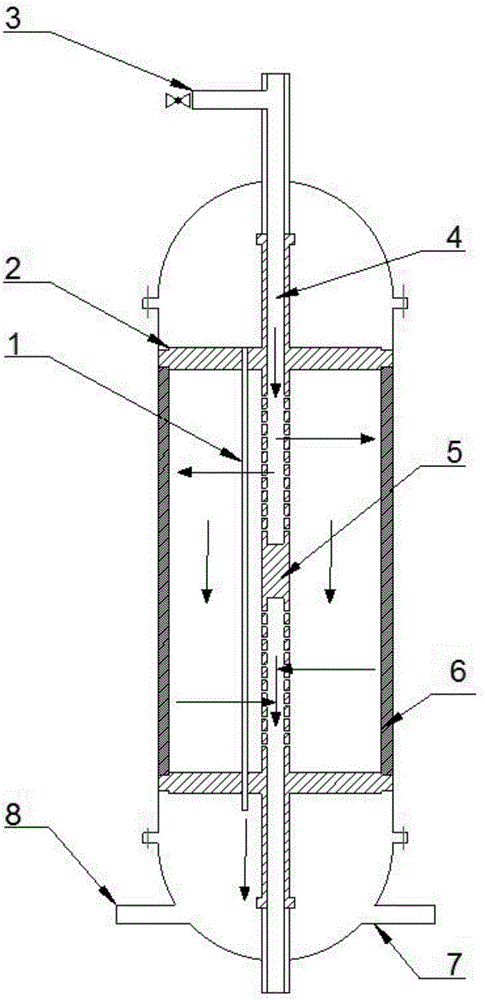

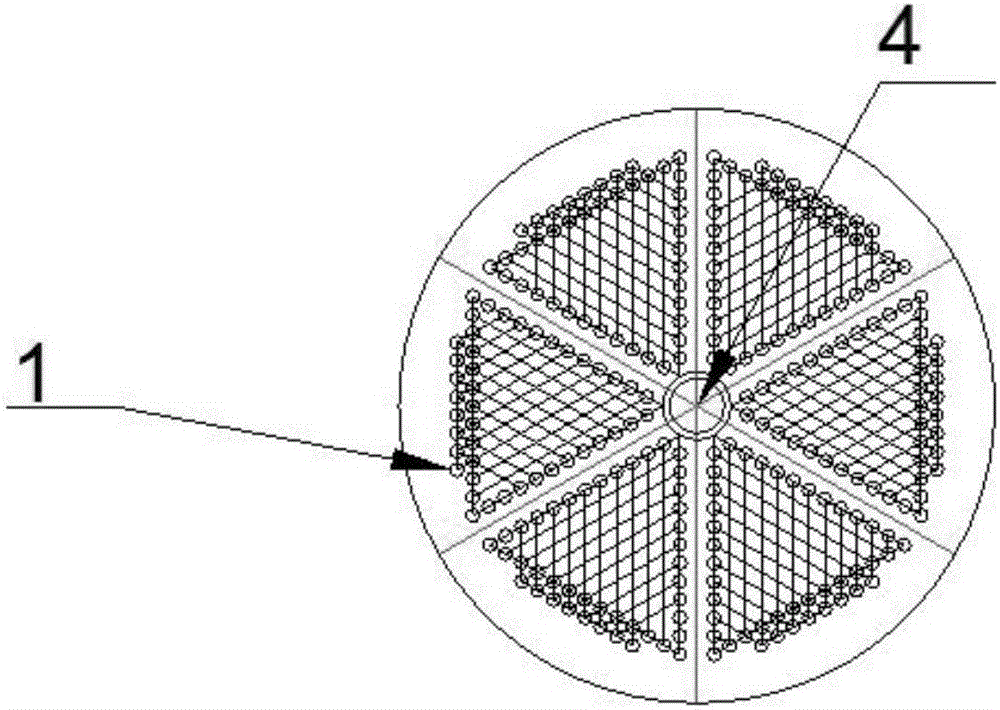

[0029] like figure 1 As shown, the present embodiment provides an emulsion microfiltration circulation system, including a waste liquid storage tank, an oil separation sedimentation tank, a hydrocyclone, a self-cleaning filter and a microfiltration device connected in sequence; the microfiltration device includes The microfiltration tube filter, the microfiltration backwash box and the backwash collector, the microfiltration tube filter is connected with the microfiltration backwash box and the backwash collector respectively, and the microfiltration backwash box is also connected with the microfiltration pump through the backwash pump. The filter tube filter is connected, specifically, the microfiltration tube filter is circulated and backwashed through the microfiltration backwash box, and the waste liquid is collected with a backwash collector after backwashing; the microfiltration device, self-cleaning filter The slurry collected by the hydrocyclone and the waste liquid st...

Embodiment 2

[0035] This embodiment provides a kind of emulsion microfiltration circulation process based on embodiment 1, comprising the following steps:

[0036] S1. Inclined plate oil-separation precipitation: the steel rolling waste emulsion containing iron powder and ash is separated from oil with an inclined plate with an inclination angle of 45°~60°. The oil particle retention rate is 0.2mm / s, and the particle size is 60μm and above oil particles;

[0037] S2. Hydrocyclone treatment: the waste emulsion treated by S1 is passed into the hydrocyclone, and the large particles in the feed liquid enter the conical cylinder at the lower part of the hydrocyclone and are removed. The outlet of the upper part of the hydrocyclone is discharged;

[0038] S3. Self-cleaning filtration treatment: pass the supernatant liquid discharged from S2 into a self-cleaning filter to filter and discharge sewage, and remove particulate impurities with a particle size of 130 μm and above;

[0039] S4. Microf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com