Heavy-metal-containing flotation wastewater treatment and recycling technique

A flotation wastewater recycling technology, applied in flotation water/sewage treatment, mining wastewater treatment, reflux water treatment, etc., can solve problems such as environmental pollution of flotation wastewater containing heavy metals, achieve resource saving, convenient and accurate control , the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

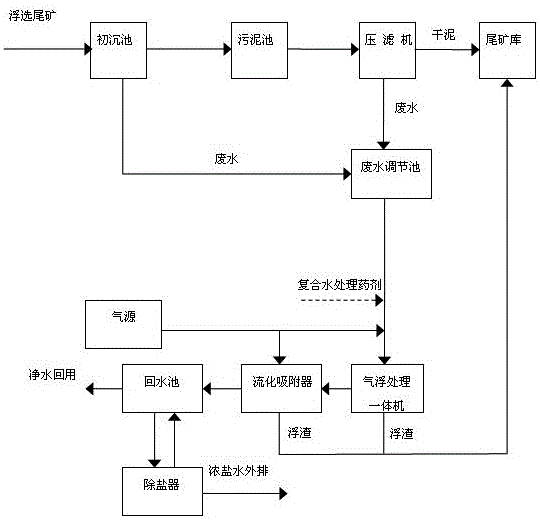

[0019] Example 1: A heavy metal-containing flotation wastewater treatment and resource recycling process. The flotation tailings are first subjected to primary sedimentation, coagulation treatment, and air flotation to remove suspended solids, foaming agents and collectors. Then it is sent to a fluidized adsorber to further remove the residual foaming agent and collector. The effluent is then passed through a resin exchange desalinizer to remove sodium and potassium salts. The primary sludge is pumped into the filter press for dehydration and then discharged into the tailings pond. Enter the conditioning tank to continue processing. The amount of coagulant added in the coagulation treatment process is based on 100 grams per ton of wastewater.

[0020] The air source used in the air flotation method is air, and the collector butyl xanthate is oxidized to grease-like substances and removed by air flotation.

[0021] The fluidized adsorber uses dissolved air water microbubbles as the...

Embodiment 2

[0030] A process for the treatment and recycling of heavy metal flotation wastewater. The flotation tailings are first subjected to primary sedimentation, coagulation treatment, and air flotation to remove suspended solids, foaming agents and collectors, and then sent to the stream The chemical adsorber further removes the residual foaming agent and collector, the effluent is then passed through a resin exchange desalinizer to remove sodium and potassium salts, the primary sludge is pumped into the filter press for dehydration and then discharged into the tailings pond, and the filtered water enters the regulating tank to continue deal with.

[0031] The amount of coagulant added in the coagulation treatment process is 270 grams per ton of wastewater.

[0032] The gas source used in the air flotation method is ozone, and the collector butyl xanthate is oxidized into oils and fats and removed by air flotation.

[0033] The fluidized adsorber adopts dissolved gas water microbubbles as...

Embodiment 3

[0038] A process for the treatment and recycling of heavy metal flotation wastewater. The flotation tailings are first subjected to primary sedimentation, coagulation treatment, and air flotation to remove suspended solids, foaming agents and collectors, and then sent to the stream The chemical adsorber further removes the residual foaming agent and collector, the effluent is then passed through a resin exchange desalinizer to remove sodium and potassium salts, the primary sludge is pumped into the filter press for dehydration and then discharged into the tailings pond, and the filtered water enters the regulating tank to continue deal with.

[0039] The amount of coagulant added in the coagulation treatment process is based on 25 grams per ton of wastewater.

[0040] The gas source used in the air flotation method is ozone, and the collector butyl xanthate is oxidized into oils and fats and removed by air flotation.

[0041] The fluidized adsorber adopts dissolved air water microbu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com