Method for improving biological treatment efficiency of waste water containing triclocarban pollutants

A technology for triclocarban and biological treatment, which is used in neutralization water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

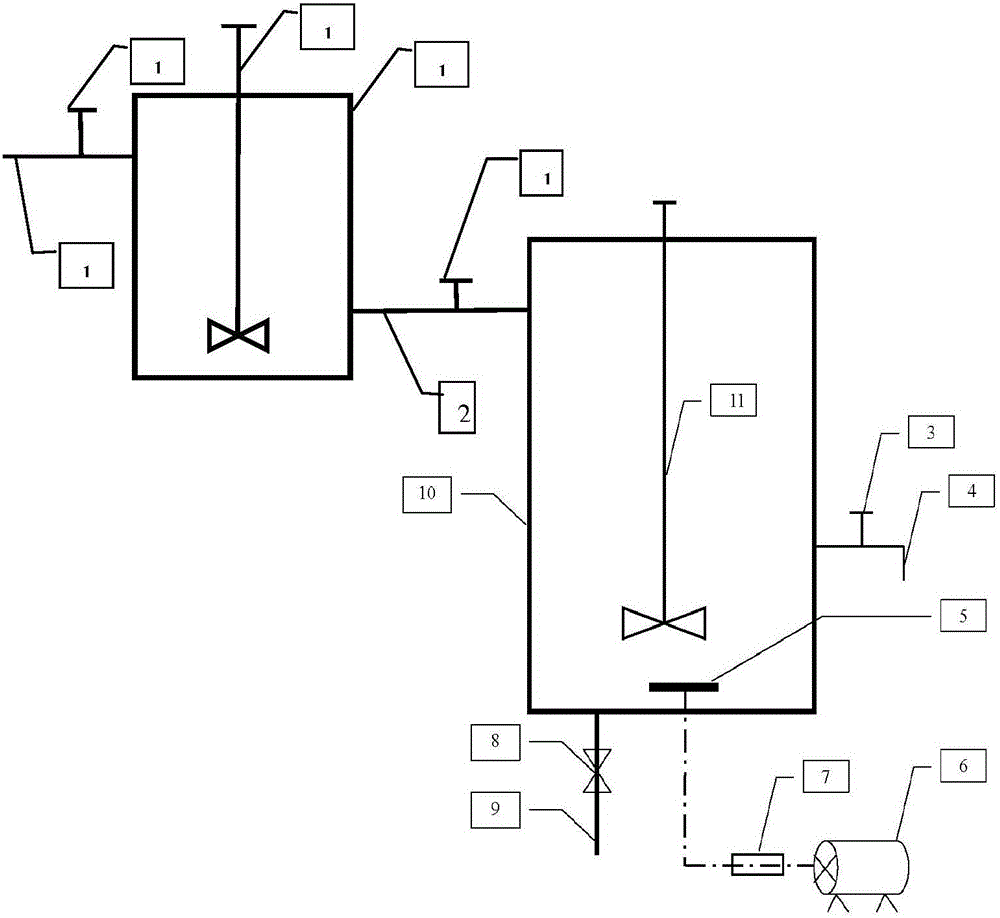

Image

Examples

Embodiment 1

[0038] The simulated urban domestic sewage was treated in the above operating device with the simulated wastewater only added with DMF and the simulated wastewater added with DMF dissolved in TCC. The carbon source is mainly sodium acetate, ammonium chloride is used to simulate ammonia nitrogen in sewage, potassium dihydrogen phosphate is used to simulate soluble phosphate in sewage, and the influent COD is 300-350mg·L -1 , TN is 32~38mg·L -1 , TP is 10~12mg·L -1 , TCC concentration 5mg·L -1 , the concentration of DMF is 0.2mg·L -1 . After stable operation, the NO3- content at the end of the first anaerobic stage in the reactor with only DMF added was 120.08±1.45mg·L -1, the NO3- content at the end of the first anaerobic stage in the TCC wastewater dissolved in DMF was 50.89±2.45mg·L -1 . Visible, adopt the present invention to add DMF in sewage and utilize multi-stage SBR process, TCC can be combined about 60-70mg L at the end of anaerobic stage -1 NO 3 - , to reduce...

Embodiment 2

[0040] According to the device and the method described in Example 1, the daily chemical wastewater with a content of about 50 mg / LTCC was treated respectively. Influent COD is 800~1000mg·L -1 , TN is 26.8~41.2mg·L -1 , TP is 4.3~7.2mg·L -1 , adding 5ml / L of DMF, using a multi-stage anoxic-aerobic-anaerobic SBR process. After stable operation, in the daily chemical wastewater without adding DMF, the TCC content in the final effluent is 5.08±1.2mg·L -1 , TCC content in sludge is 35.27±1.2mg·L -1 , the biological treatment is about 20.65±2.09%, and the final result of applying the treatment of the present invention is: the TCC content in the final effluent is 3.08±0.78mg L -1 , TCC content in sludge 25.27±1.2mg·L -1 , the biological treatment is about 46.46±1.79%. It shows that the efficiency of biological treatment of TCC by applying the present invention is increased by 25.81±0.76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com