Associative thickening vac-veova emulsion and preparation method thereof

A technology of associative thickening and tertiary vinegar emulsion, which is applied in the direction of coating, etc., can solve the problems of unfavorable water-based coating construction, negative impact of scrub resistance, and rapid decrease in viscosity, so as to improve monomer conversion rate and thickening efficiency , Improve the effect of high shear viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

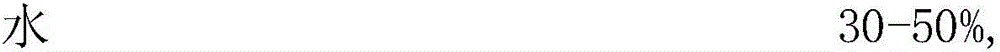

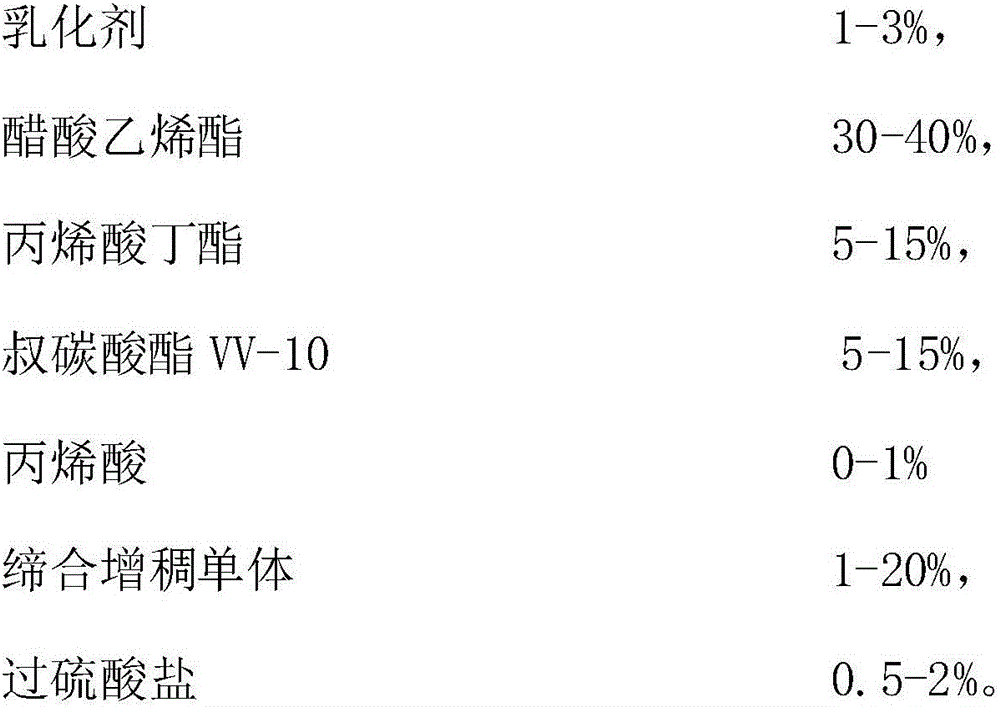

Method used

Image

Examples

Embodiment 1

[0025] Vinyl acetate 32% (weight percentage, the same below), butyl acrylate 10%, tertiary carbonate 6%, acrylic acid 0.2%, allyl polyoxyethylene ether ammonium sulfate 2%, ammonium persulfate 1.8%, association increase Thick monomer CBH 3%, water 45%.

Embodiment 2

[0027] Vinyl acetate 38% (weight percentage, the same below), butyl acrylate 5%, tertiary carbonate 7%, acrylic acid 0.2%, sodium vinyl sulfonate 2%, ammonium persulfate 1.8%, associative thickening monomer BEM 1%, water 45%.

Embodiment 3

[0029] Vinyl acetate 30% (weight percentage, the same below), butyl acrylate 10%, tertiary carbonate 10%, acrylic acid 0.2%, vinyl sodium sulfonate 1.5%, 3-Allyloxy-2-hydroxy-1-propanesulfonic acid sodium salt 0.5%, potassium persulfate 1.3%, associative thickening monomer SEM 1.5%, water 45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com