Anti-tear and anti-puncture greenhouse film and preparation method thereof

A greenhouse film and tear-resistant technology, applied in the field of plastic film, can solve the problems of easy puncture, shortened service life, weak tear resistance of greenhouse film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A tear-resistant and puncture-resistant greenhouse film of the present embodiment is composed of the following components by weight:

[0057] LLDPE 18 parts

[0058] LDPE 20 parts

[0059] BOPET 65 servings

[0060] PE antioxidant 10 parts

[0061] Ultraviolet absorber UV-531 0.8 parts

[0062] Titanium oxide or carbon black 0.2 parts

[0063] dripping agent 3 parts

[0064] Surfactant 4 parts

[0065] Toughener 5 parts

[0066] Metallocene polyethylene 30 parts

[0067] Polyphthalamide 1 part.

[0068] The preparation method of above-mentioned tear-resistant puncture greenhouse film is as follows:

[0069] (1) Feeding: Add the ingredients of the above-mentioned tear-resistant and puncture-resistant greenhouse film into the mixer in proportion;

[0070] (2) Stir evenly: the mixer fully mixes the materials added in step (1) and stirs evenly;

[0071] (3) Drying: Dry the material evenly stirred in step (2) until the moisture content is below 45ppm;

[0072] (4...

Embodiment 2

[0079] The main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this example and Example 1 is that, among the components of the tear-resistant and puncture-resistant greenhouse film, the weight part of LDPE is 30 parts by weight, the weight part of PE antioxidant is 20 parts, and the weight part of metallocene polyethylene is 40 parts.

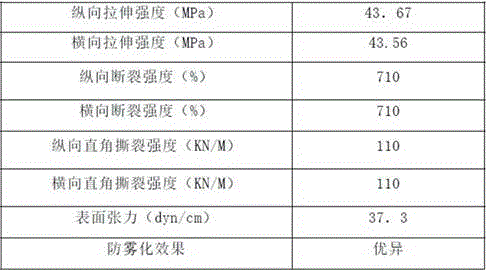

[0080] The film property test data of table 2 embodiment 2:

[0081]

Embodiment 3

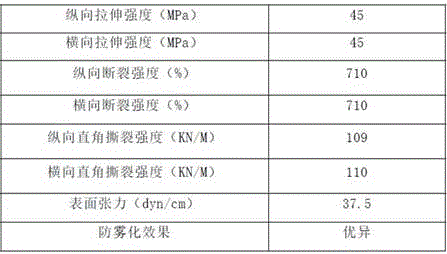

[0083] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this example and Example 1 is that, among the ingredients of the tear-resistant and puncture-resistant greenhouse film, the parts by weight of LDPE are 25 parts by weight, the parts by weight of PE antioxidant are 15 parts, and the parts by weight of metallocene polyethylene are 35 parts .

[0084] The film property test data of table 3 embodiment 3:

[0085]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com