Self-closing type polyurethane waterproof coating and method for preparing same

A polyurethane waterproof and self-closing technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor weather resistance, achieve strong weather resistance, improve adhesion, and solve the effects of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

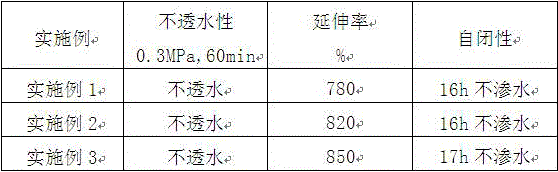

Examples

Embodiment 1

[0020] 一种自闭型聚氨酯防水涂料,由A、B两种组分构成;其中,A组分由如下重量比的原料组成:己二酸7份、HMDI 18份、2,6-二异氰酸基己酸甲酯18份、辛酸亚锡 0.1份、聚醚多元醇40份、DBTL 0.1份; B组分由如下重量比的原料组成:端羟基聚丁二烯10份、轻质碳酸钙10份、膨润土15份、白炭黑4份、固化剂15份、有机铋0.1份、溶剂油20份、消泡剂1份、扩链剂15份、氯化石蜡40份。

[0021] A、B两种组分的质量比为A 组分:B 组分=2:1.。

[0022] 固化剂为三乙基三胺。

[0023] 溶剂油为异构烷烃溶剂油。

[0024] 有机铋为异辛酸铋。

[0025] 本实施例还提供了一种自闭型聚氨酯防水涂料的制备方法,包括以下步骤:

[0026] (1)A组分制备:

[0027] 向反应釜一中加入己二酸,以0.6m 3 / h通入氮气,升温至65℃;向混合罐中加入 2,6-二异氰酸酯基己酸甲酯和HMDI,以转速75 r / min,搅拌9min,将混合罐中的液体缓慢滴加到反应釜一中;向反应釜一中加入DBTL、辛酸亚锡,升温至85℃,70r / min 搅拌反应1.5h;关闭氮气,再加入聚醚多元醇,在110℃、-0 .05MPa条件下,真空脱水1h;降温到55℃,即得 A 组分 ;

[0028] (2)B组分制备

[0029] 在反应釜二中加入端羟基聚丁二烯,升温至90℃,加入轻质碳酸钙、膨润土、白炭黑,分散10min,转速为350r / min;将反应釜二降温至70℃,加入固化剂、有机铋、溶剂油、消泡剂、扩链剂、氯化石蜡,以100r / min搅拌30min;在110℃下,真空脱水0.5h,真空压力为-0.05MPa;降温至55℃,即得B组分;

[0030] (3)配制防水涂料:

[0031] 将A组分和 B 组分按比例混合即可形成自闭型聚氨酯防水涂料。

Embodiment 2

[0033] 一种自闭型聚氨酯防水涂料,由A、B两种组分构成;其中,A组分由如下重量比的原料组成:己二酸7-10份、HMDI 24份、2,6-二异氰酸基己酸甲酯20 份、辛酸亚锡 0.1-0.3 份、聚醚多元醇55份、DBTL 0.3份; B组分由如下重量比的原料组成:端羟基聚丁二烯25份、轻质碳酸钙20份、膨润土25份、白炭黑6份、固化剂15-35份、有机铋0.5份、溶剂油30份、消泡剂2份、扩链剂25份、氯化石蜡55份。

[0034] A、B两种组分的质量比为A 组分:B 组分=3:1

[0035] 固化剂为三乙基三胺。

[0036] 溶剂油为异构烷烃溶剂油。

[0037] 有机铋为异辛酸铋。

[0038] 本实施例还提供了一种自闭型聚氨酯防水涂料的制备方法,包括以下步骤:

[0039] (1)A组分制备:

[0040] 向反应釜一中加入己二酸,以0.8m 3 / h通入氮气,升温至75℃;向混合罐中加入 2,6-二异氰酸酯基己酸甲酯和HMDI,以转速80 r / min,搅拌11min,将混合罐中的液体缓慢滴加到反应釜一中;向反应釜一中加入DBTL、辛酸亚锡,升温至90℃, 80 r / min 搅拌反应2.5h;关闭氮气,再加入聚醚多元醇,在120℃、-0 .06MPa条件下,真空脱水2h;降温到65℃,即得A 组分 ;

[0041] (2)B组分制备

[0042] 在反应釜二中加入端羟基聚丁二烯,升温至110℃,加入轻质碳酸钙、膨润土、白炭黑,分散20min,转速为450r / min;将反应釜二降温至80℃,加入固化剂、有机铋、溶剂油、消泡剂、扩链剂、氯化石蜡,以120r / min搅拌50min;在120℃下,真空脱水1h,真空压力为-0.06MPa;降温至65℃,即得B组分;

[0043] (3)配制防水涂料:

[0044] 将A组分和 B 组分按比例混合即可形成自闭型聚氨酯防水涂料。

Embodiment 3

[0046] 一种自闭型聚氨酯防水涂料,由A、B两种组分构成;其中,A组分由如下重量比的原料组成:己二酸8.5份、HMDI 21份、2,6-二异氰酸基己酸甲酯19 份、辛酸亚锡 0.2 份、聚醚多元醇47份、DBTL 0.2份; B组分由如下重量比的原料组成:端羟基聚丁二烯17份、轻质碳酸钙15份、膨润土20份、白炭黑5份、固化剂25份、有机铋 0.3份、溶剂油25份、消泡剂1.5份、扩链剂20份、氯化石蜡47份。

[0047] A、B两种组分的质量比为A 组分:B 组分=2.5:1

[0048] The curing agent is triethyltriamine.

[0049] Solvent oil is isoparaffin solvent oil.

[0050] Organic bismuth is bismuth isooctanoate.

[0051] Present embodiment also provides a kind of preparation method of self-closing type polyurethane waterproof coating, comprises the following steps:

[0052] (1) Preparation of component A:

[0053] Add adipic acid to the reaction kettle one, with 0.7m 3 Nitrogen gas was introduced per hour, and the temperature was raised to 70°C; 2,6-diisocyanatohexanoic acid methyl ester and HMDI were added to the mixing tank, stirred at a speed of 77r / min for 10min, and the liquid in the mixing tank was slowly added dropwise to the reaction Kettle 1; add DBTL and stannous octoate to reactor 1, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com