Temperature sensitive adhesive

A temperature-sensitive, adhesive technology, applied in the direction of adhesive types, rosin adhesives, ester copolymer adhesives, etc., can solve the problems of attaching and peeling, screaming, and damage to the adherend, etc. Achieves excellent heat resistance and suppresses squealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

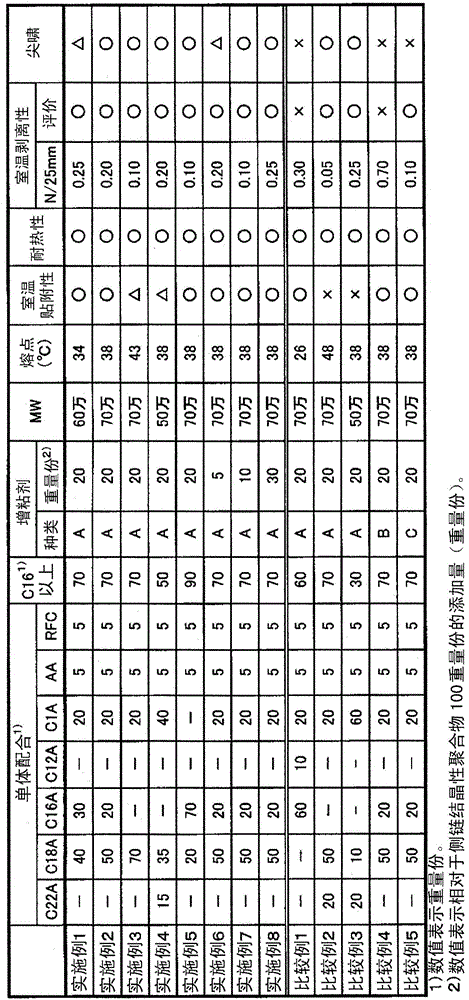

Embodiment 1~8 and comparative example 1~5

[0054]

[0055] First, the monomers shown in Table 1 were mixed in the proportions (parts by weight) shown in Table 1 to obtain a mixture. In addition, the total ratio of the (meth)acrylate which has a C16 or more linear alkyl group is shown in the column of "C16 or more" in Table 1.

[0056] The monomers used are as follows.

[0057] C22A: behenyl acrylate

[0058] C18A: stearyl acrylate

[0059] C16A: cetyl acrylate

[0060] C12A: lauryl acrylate

[0061] C1A: methyl acrylate

[0062] AA: Acrylic

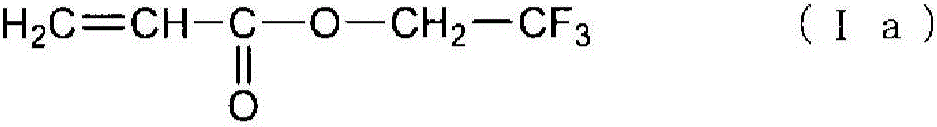

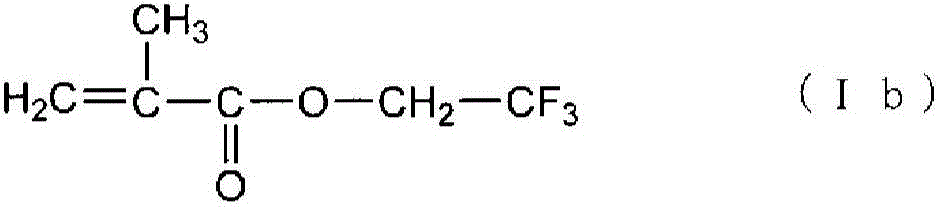

[0063] RFC: Reactive fluorine compound "Viscoat 3F" represented by the above-mentioned formula (Ia) manufactured by Osaka Organic Chemical Industry Co., Ltd.

[0064] Next, the obtained mixture was added to 200 parts by weight of a mixed solvent of ethyl acetate:toluene=8:2 (weight ratio) to obtain a mixed liquid. The obtained liquid mixture was stirred at 55° C. for 4 hours to polymerize each monomer to obtain a side chain crystalline polymer.

[0065] Next, a thickener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com