Method of environmentally friendly chemical nickel plating

An environment-friendly, electroless nickel plating technology, applied in the field of material science, can solve the problem of low corrosion resistance of the coating, and achieve the effects of high corrosion resistance, bright corrosion resistance, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

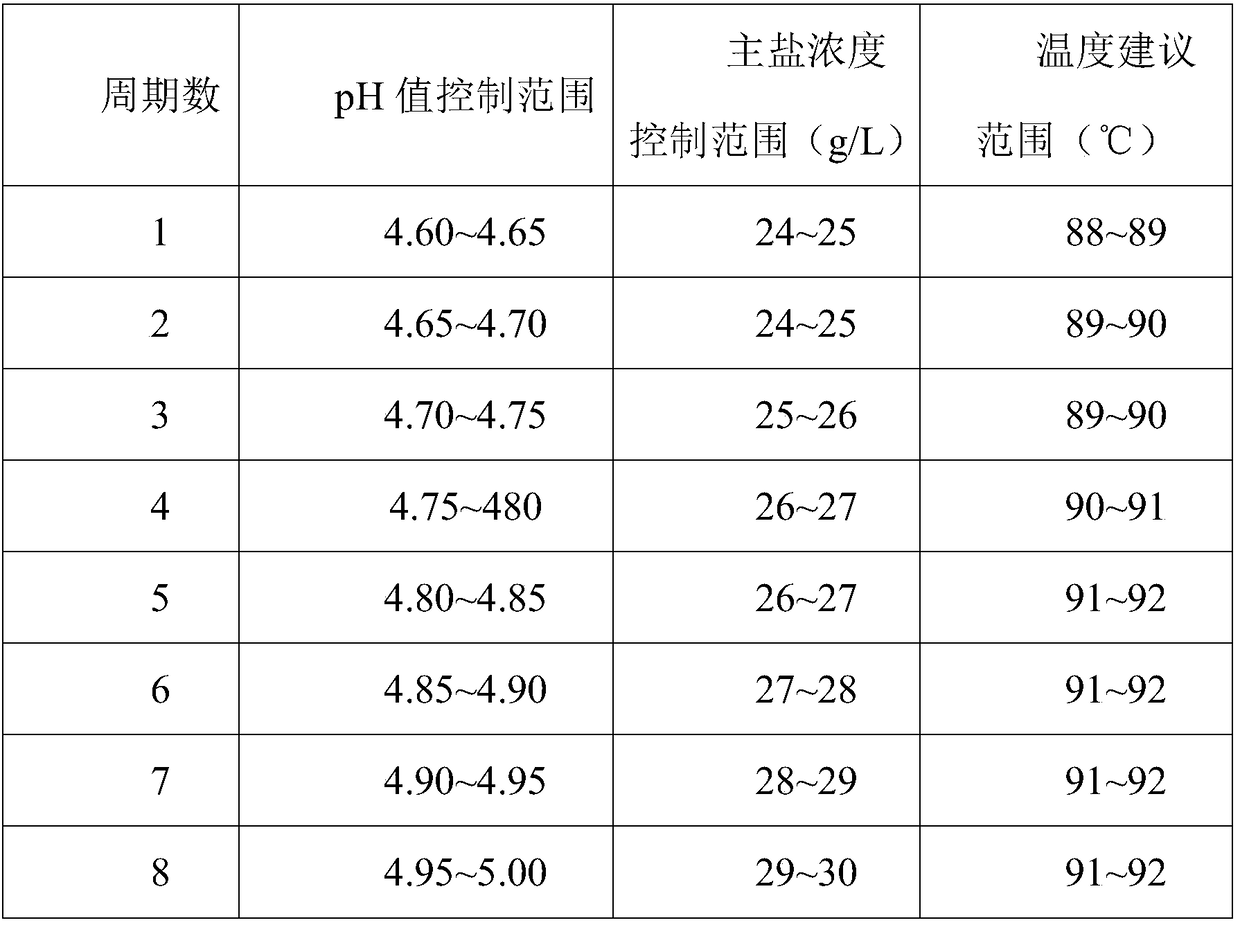

[0019] Embodiments of the invention: a method for environmentally friendly electroless nickel plating,

[0020] 1. Liquid preparation and tank preparation method

[0021] (1) Preparation of liquid A (for tank preparation and addition, based on the preparation of 50L)

[0022] Dissolve 12.5kg of nickel sulfate (hexahydrate) in 35L of pure water. After dissolving, add 4.5kg of citric acid (monohydrate), 2.0L of lactic acid (88%), and 1.25g of benzimidazole. Stir and mix well, then add water to 50L , adjust the pH value to 4.60±0.02 with 20% sodium hydroxide solution and 1+1 ammonia water, and save it for later use;

[0023] (2) Preparation of liquid B (for tank preparation, calculated on the basis of preparation of 50L)

[0024] First dissolve 7.5kg of sodium hypophosphite with about 35L of pure water. After dissolving, add 3.75kg of crystalline sodium acetate, 3.25kg of citric acid (monohydrate), 1.5L of lactic acid, 1.875g of benzimidazole, and 2-ethyl Sodium hexyl sulfate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com