Ethanol gas sensor based on ZnO/SnO2 heterostructure composite material and preparation method thereof

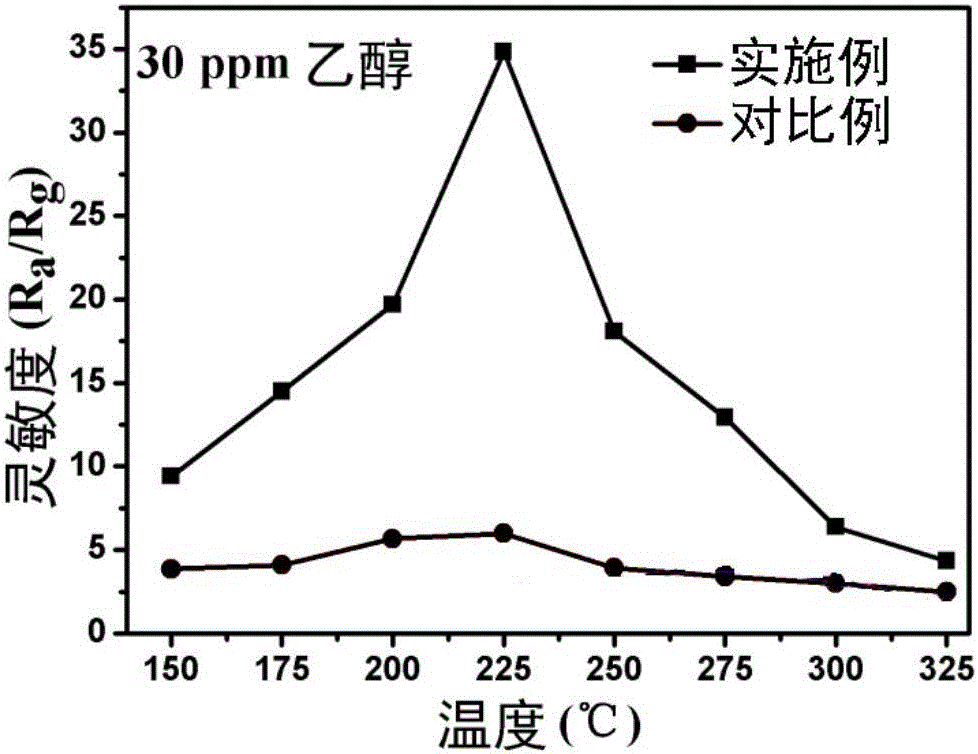

A gas sensor and composite material technology, applied in the direction of electrochemical variables of materials, tin oxide, etc., can solve the problems of low sensitivity and high detection limit, and achieve the effect of improving sensitivity, broad application prospects and suitable for mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

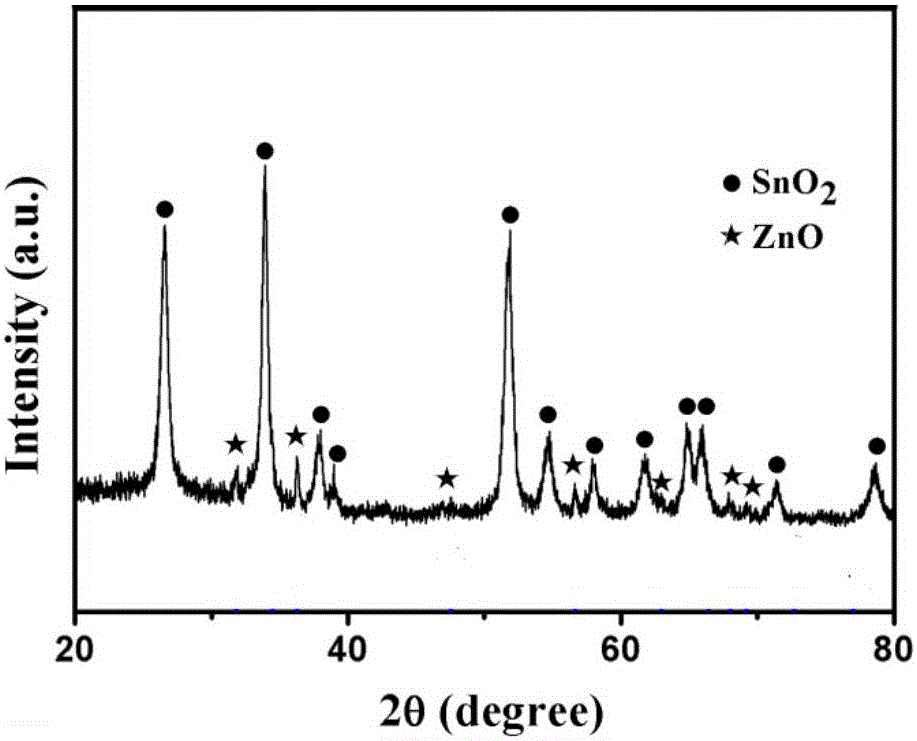

[0039] with hollow spherical SnO 2 / CeO 2 Heterostructure composite oxide semiconductor materials are used to make ethanol gas sensors, and the specific manufacturing process is as follows:

[0040] 1. First mix ethanol and deionized water at a ratio of 10:1 to form a 33mL solution, and then add 0.2g of SnCl to it 2 2H 2 O and 0.5mL hydrochloric acid with a mass fraction of 38%, sonicate for 20min at 30°C;

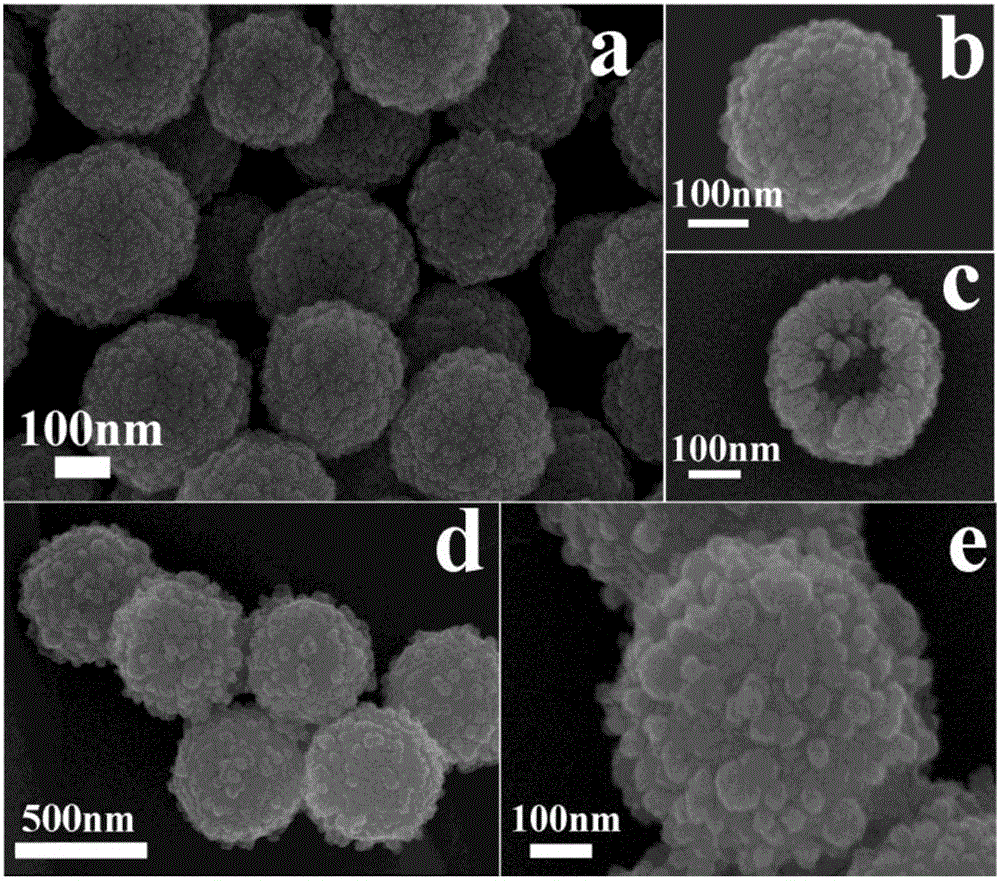

[0041] 2. Transfer the above solution to a reaction kettle with a volume of 40mL, react at 200°C for 24 hours, and after cooling to room temperature, wash the formed precipitate with deionized water and ethanol several times, and then dry it at room temperature before putting it in Calcined at 400 °C for 2 hours, thus obtained the SnO 2 Hollow spherical SnO assembled from nanoparticles 2 ; The diameter of the hollow sphere is between 200 and 400nm, and the thickness of the spherical shell is between 100 and 150nm.

[0042] 3. Take 30mg of the above hollow spherical S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com