A method for detecting dislocation density in ultra-low carbon steel by snoek relaxation internal friction peak method

A technology of ultra-low carbon steel and internal friction, applied in the field of physical performance testing of metal materials, can solve problems such as difficult sample preparation, cumbersome data processing, and stability impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] In this example, see Figure 1 to Figure 4 , a method for detecting the dislocation density of ultra-low carbon steel using the Snoek relaxation internal friction peak method, comprising the steps of:

[0068] a. Detect the carbon content of ultra-low carbon steel: take ultra-low carbon steel samples, calculate the carbon atomic percentage C (at%) of ultra-low carbon steel samples, and record the ultra-low carbon steel cold working deformation to the test of internal friction The time t(s) at room temperature;

[0069] b. Make the Snoek relaxation internal friction test sample: cut and make a rod-shaped metal sample with a sample size of 1*2*55mm from the ultra-low carbon steel sample taken in the step a, and carry out the follow-up Before the test, use an ultrasonic cleaner to clean the rod-shaped metal sample, so that the surface of the rod-shaped metal sample is clean and pollution-free, and use the cleaned and treated rod-shaped metal sample as the sample to be tes...

Embodiment 2

[0084] This embodiment is basically the same as Embodiment 1, especially in that:

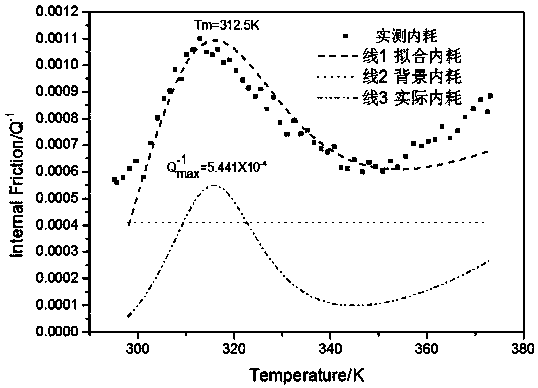

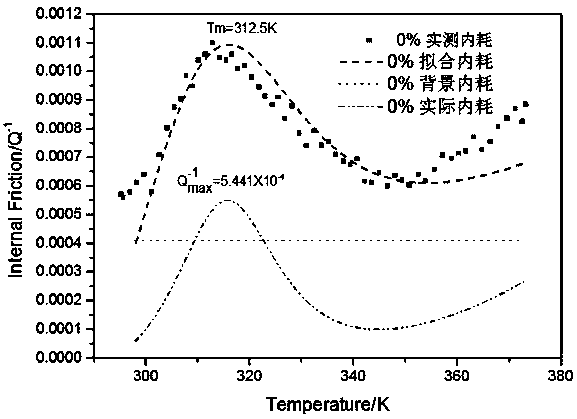

[0085] In this example, see Figure 5 ~ Figure 7 , when using the Snoek relaxation internal friction peak method to detect the dislocation density of ultra-low carbon steel, the ultra-low carbon steel sample is detected by the sulfur and nitrogen combustion instrument, and the carbon atomic percentage is 4.67×10 -3 % of ultra-low carbon steel, the time t at room temperature between cold working deformation and internal friction measurement is three months (324000s). The deformation of the sample is 5%. The internal friction test sample is a 1*2*55mm rod-shaped sample. The surface is roughly ground and polished, and the internal friction test is carried out by ultrasonic cleaning. see Figure 5 , the true Snoek relaxation internal friction peak peak temperature of the sample with 5% deformation is 320K, and the real peak height of the Snoek relaxation internal friction peak is 4.90×10 -4 , th...

Embodiment 3

[0087] This embodiment is basically the same as the previous embodiment, and the special features are:

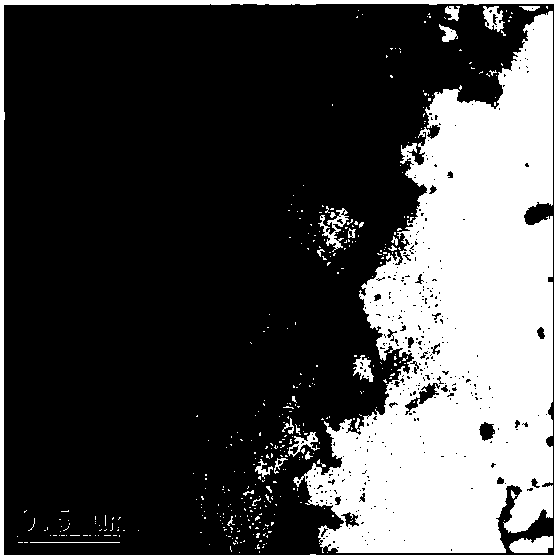

[0088] In this example, see Figure 8 ~ Figure 10 , when using the Snoek relaxation internal friction peak method to detect the dislocation density of ultra-low carbon steel, the ultra-low carbon steel sample is detected by the sulfur and nitrogen combustion instrument, and the carbon atomic percentage is 4.67×10 -3 % of ultra-low carbon steel, the time t at room temperature between cold working deformation and internal friction measurement is three months (324000s). The deformation of the sample is 10%. The internal friction test sample is a 1*2*55mm rod-shaped sample. The surface is roughly ground and polished, and the internal friction test is carried out by ultrasonic cleaning. see Figure 8 , when the deformation amount is 10%, the peak temperature of the real Snoek relaxation internal friction peak of ultra-low carbon steel is 313K, and the peak height is 4.90×10 -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com