Lithium ion battery additive, lithium ion battery containing lithium ion battery additive and preparation method of lithium ion battery

A lithium-ion battery and additive technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low initial Coulombic efficiency, consumption of active lithium ions, etc., and achieve the effect of improving reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present application also relates to the preparation method of the lithium ion battery, comprising adding the additive in the following manner:

[0056] Step 1, dissolving the additive described in the present application in the first organic solvent to obtain solution A, and dissolving the lithium salt in the second organic solvent to obtain solution B;

[0057] Step 2, injecting solution A into the lithium-ion battery; and

[0058] Step 3, inject solution B into the lithium-ion battery.

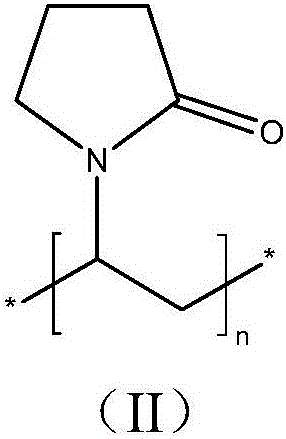

[0059] The present application has found through research that directly adding polyvinylpyrrolidone compounds to organic solvents containing lithium salts will lead to the precipitation of polyvinylpyrrolidone compounds, so it is necessary to add Solution B containing lithium salt. Under the action of lithium salt, polyvinylpyrrolidone compounds are precipitated to form a film, which is coated on the surface of the electrode sheet and separator, and provides a skeleton for the s...

Embodiment 1~6

[0070] (1) Preparation of positive electrode sheet for lithium ion battery

[0071] The positive electrode active material lithium nickel cobalt manganese oxide (LiNi 0.6 co0.2 mn 0.2 o 2 ), the conductive agent Super-P, and the binder polyvinylidene fluoride (PVDF) were dissolved in the solvent N-methylpyrrolidone at a mass ratio of 97.2:1.3:1.5 and mixed evenly to make a positive electrode slurry, and then the positive electrode slurry was evenly coated Spread on the front and back sides of the current collector aluminum foil, the coating amount is 0.0102g / cm 2 , followed by drying at 85°C, cold pressing, trimming, cutting, and stripping, and then drying at 85°C under vacuum for 4 hours, welding the tabs, and making the positive electrode sheet of the lithium-ion battery.

[0072] (2) Preparation of the negative electrode sheet of the lithium-ion battery

[0073] Negative active material artificial graphite, conductive agent Super-P, thickener carboxymethyl cellulose (CM...

Embodiment 7~11

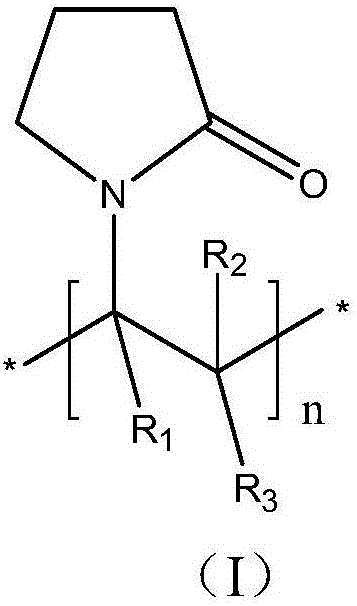

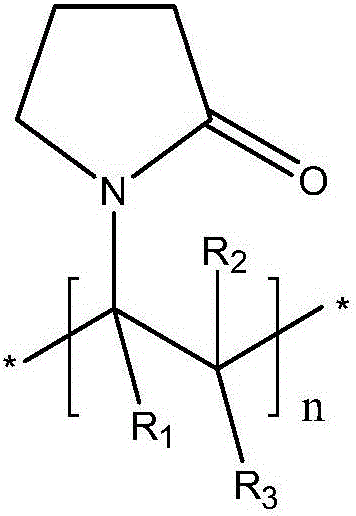

[0100] Electrolyte and the lithium-ion battery containing the electrolytic solution are prepared according to the method of Example 1, the difference is: the compound structural formula and the addition ratio of the additive in the electrolytic solution are as shown in Table 2, and the ratio of the additive is based on its ratio in the electrolytic solution content calculation.

[0101] Table 2

[0102]

[0103]

[0104] The performance of the prepared batteries was tested according to the method in Example 1, and the performances of batteries 7-11 were similar to those of the above examples, and will not be repeated due to space limitations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com