Grinding disc arranged in order and preparation method thereof

A grinding disc and grinding rod technology, used in grinding/polishing equipment, abrasives, grinding devices, etc., can solve problems such as grinding wheel blockage, affecting processing efficiency, and affecting processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

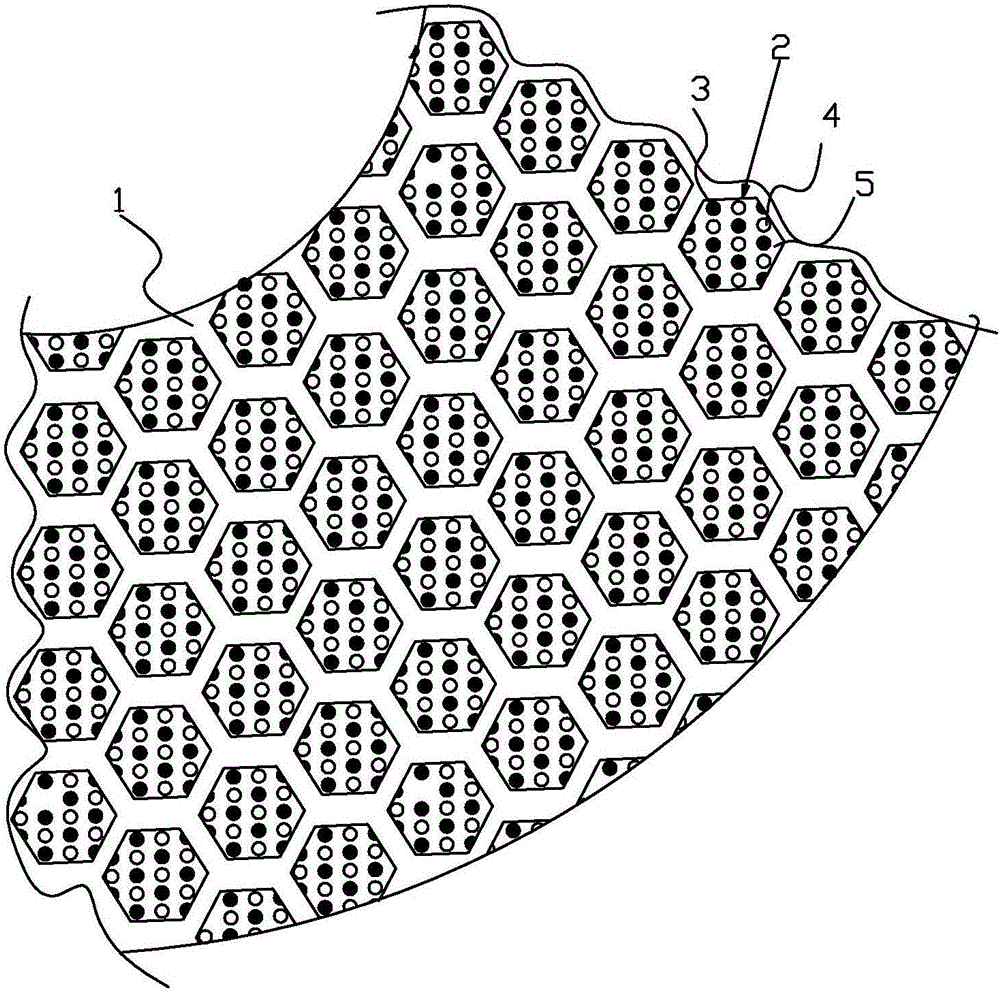

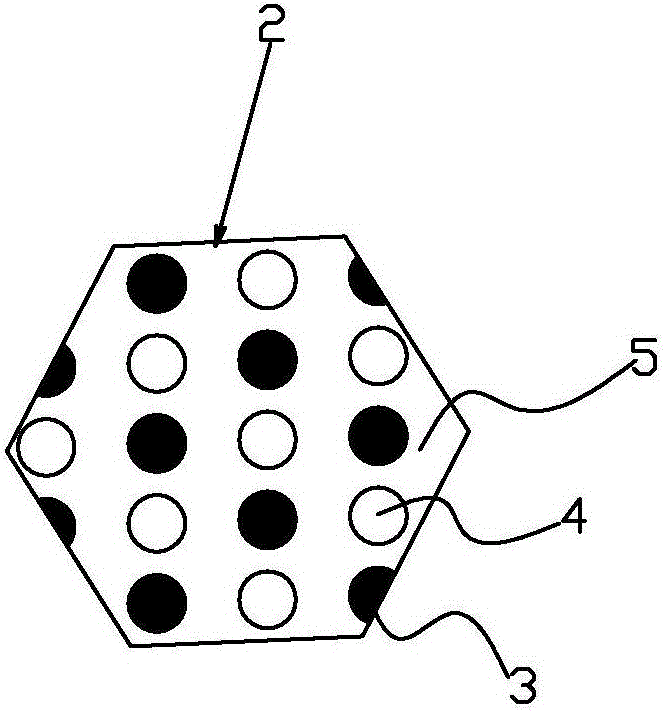

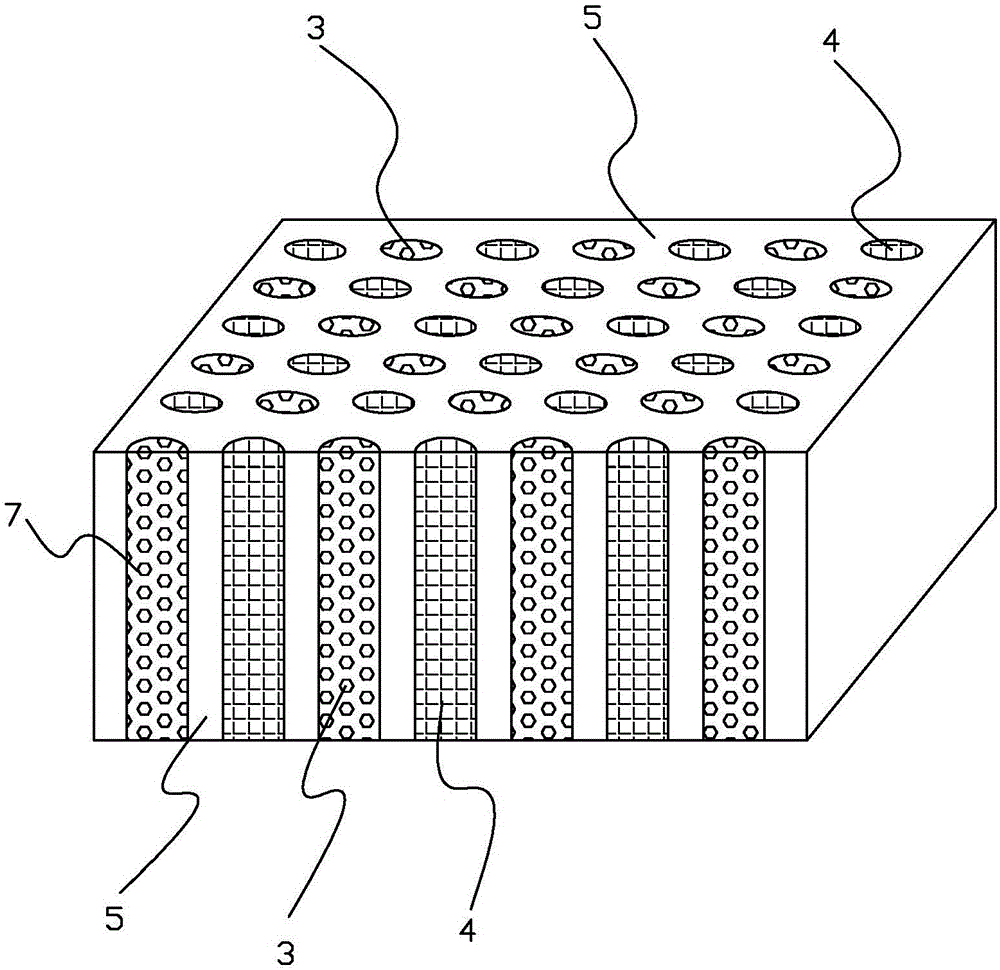

[0038] Please check figure 1 , figure 2 and image 3 , an orderly arranged diamond grinding disc, including a base disc 1 and several grinding discs 2 . Each of the grinding discs 2 includes several gel grinding rods 3 containing diamond abrasive grains, several gel grinding rods 4 not containing diamond grinding grains, and epoxy resin 5 used as a bonding agent. In this embodiment: epoxy resin is selected as the binding agent, but it is not limited to this, and any one of phenolic resin, polyimide resin, photocurable resin, thermosetting resin, etc. can also be selected as required. Mixing of the above several kinds; the abrasive grains are selected from diamond abrasive grains, but not limited to this, and any one of CBN, alumina, silicon carbide, etc., or a mixture of the above-mentioned types can also be selected as required.

[0039] The gel grinding rods 3 containing diamond abrasive grains and the gel grinding rods 4 not containing diamond grinding grains are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com