Emulsifier for milk component-containing beverages

A technology of emulsifiers and active ingredients, applied in the field of emulsifiers for beverages, can solve the unsatisfactory problems of stearoyl lactylate and achieve the effect of inhibiting quality deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

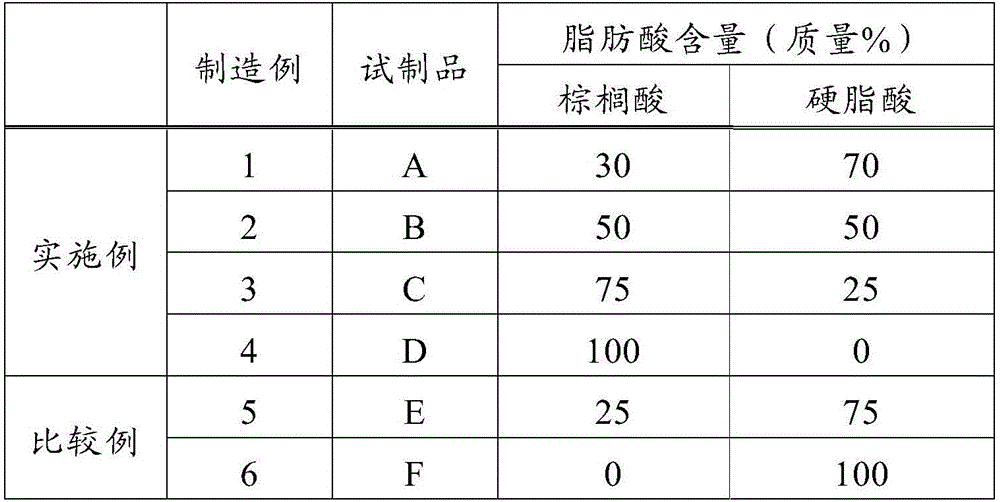

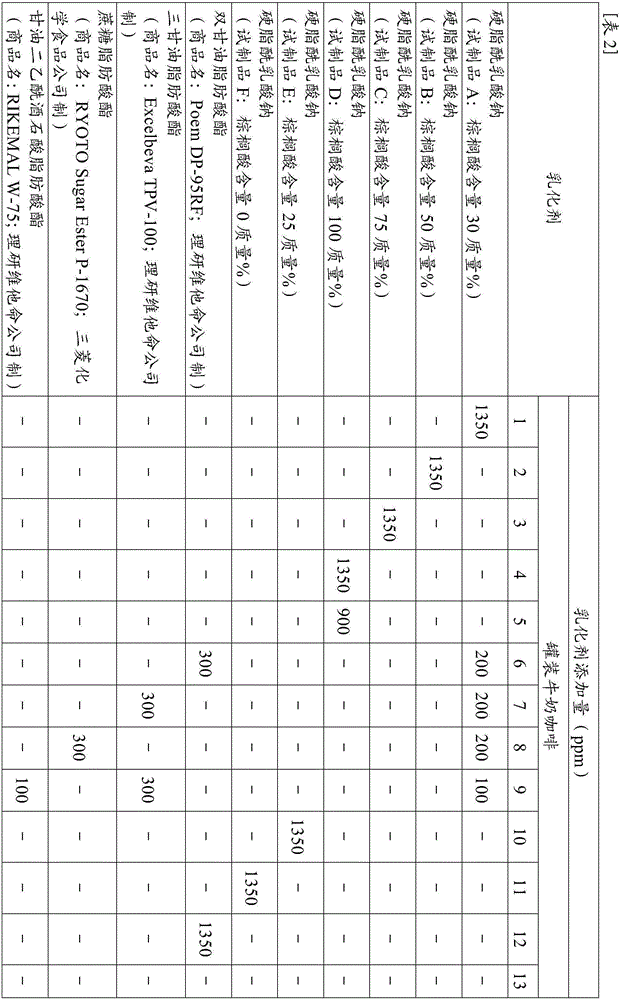

manufacture example 1

[0049] Add 123.5 g of 88 mass % lactic acid aqueous solution to the reactor equipped with a stirrer, a thermometer, a gas injection pipe and a water separator, and slowly add 58.0 g of a 48 mass % aqueous solution of sodium hydroxide while stirring it, and raise the temperature of the liquid to to 115°C, and stirred at the same temperature for 30 minutes. Next, after adding 95.7 g of palmitic acid (trade name: palmitic acid 98; manufactured by Miyoshi Oil Co., Ltd.) and 223.3 g of stearic acid (trade name: EDENOR C18-98MY; manufactured by COGNIS OLEOCHEMICALS Co., Ltd.), the mixture was heated at 175° C. under a nitrogen stream. After the normal pressure reaction for 3 hours, the reaction was carried out at the same temperature at a reduced pressure of 0.02 MPa for 30 minutes, and at the same temperature at a reduced pressure of 0.005 MPa until the acid value reached 83.5 mgKOH. Thereafter, the reaction liquid was cooled to 100° C. to obtain 424.3 g of a milk component-contain...

manufacture example 2

[0051] Add 125.6 g of 88 mass % lactic acid aqueous solution to the reaction kettle equipped with a stirrer, a thermometer, a gas injection pipe and a water separator, slowly add 58.2 g of a 48 mass % aqueous solution of sodium hydroxide while stirring it, and raise the temperature of the liquid to 115°C, and stirred at the same temperature for 30 minutes. Next, after adding 158.1 g of palmitic acid (trade name: palmitic acid 98; manufactured by Miyoshi Oil Co., Ltd.) and 158.1 g of stearic acid (trade name: EDENOR C18-98MY; manufactured by COGNISOLEOCHEMICALS Co., Ltd.), the mixture was heated at 175° C. under a nitrogen stream. After the pressure reaction for 3 hours, the reaction was carried out at the same temperature at a reduced pressure of 0.02 MPa for 30 minutes, and further at the same temperature at a reduced pressure of 0.005 MPa until the acid value reached 83.7 mgKOH. Thereafter, the reaction liquid was cooled to 100° C. to obtain 423.7 g of a milk component-conta...

manufacture example 3

[0053] Add 127.7 g of 88 mass % lactic acid aqueous solution to the reaction kettle equipped with a stirrer, a thermometer, a gas injection pipe and a water separator, slowly add 59.2 g of a 48 mass % aqueous solution of sodium hydroxide while stirring it, and raise the temperature of the liquid to 115°C, and stirred at the same temperature for 30 minutes. Next, after adding 234.9 g of palmitic acid (trade name: palmitic acid 98; manufactured by Miyoshi Oil Co., Ltd.) and 78.3 g of stearic acid (trade name: EDENOR C18-98MY; manufactured by COGNISOLEOCHEMICALS Co., Ltd.), the mixture was heated at 175° C. under a nitrogen stream. After the pressure reaction for 3 hours, the reaction was carried out at the same temperature at a reduced pressure of 0.02 MPa for 30 minutes, and at the same temperature at a reduced pressure of 0.005 MPa until the acid value reached 83.9 mgKOH. Thereafter, the reaction liquid was cooled to 100° C. to obtain 423.4 g of a milk component-containing emu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com