High-quality and high-volume phosphorous slag cement produced through phosphorus slag and production method of cement

A high-dosage, phosphorus slag technology, applied in clinker production, cement production, etc., can solve the problems of wasting natural resources, high production costs, and high energy consumption for calcination, so as to reduce energy consumption for sintering, improve utilization rate, Improves the effect of hydration activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The specific operation of using phosphorus slag to produce high-quality and high-volume phosphorus slag cement is as follows:

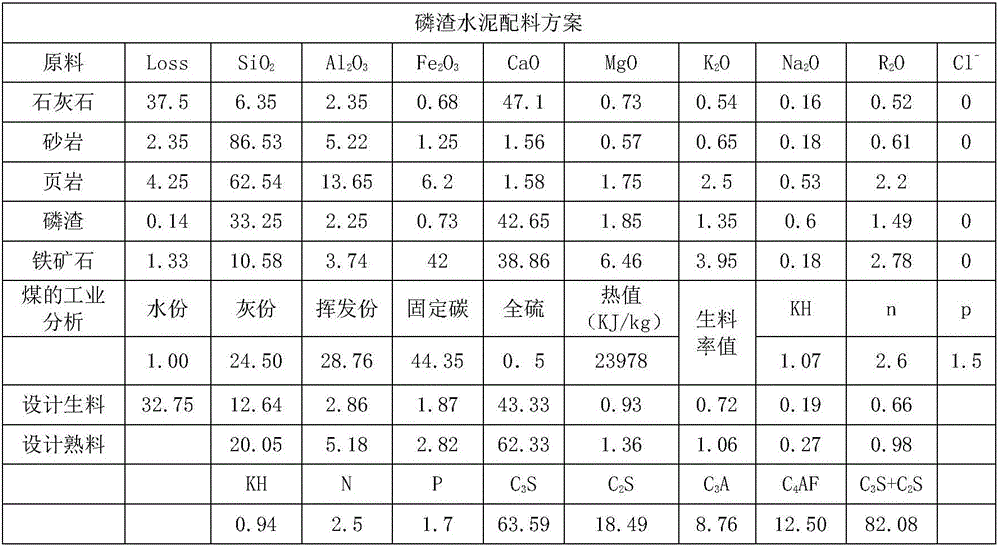

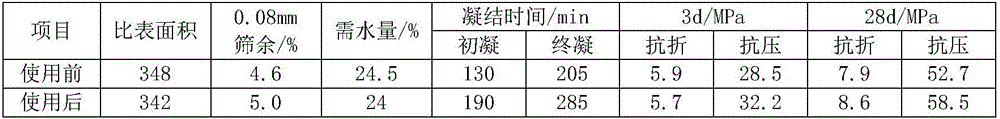

[0035] The incoming raw materials should be as stable as possible, and the main raw materials should be made from a single ore as much as possible. Shale, phosphorus slag, sandstone, limestone, and iron ore should be used as five-component ingredients, and sandstone should be used as siliceous correction material to adjust SiO in the raw meal. 2 . Make a batching plan according to the chemical composition of each raw material, put it into the raw material mill for grinding according to the ratio of the batching plan, and finally mix. Wherein the chemical composition of the raw material in implementation is shown in Table 1:

[0036] The chemical composition of table 1 raw material

[0037] raw material

SiO 2

Al 2 o 3

Fe 2 o 3

CaO

MgO

K 2 o

Na 2 o

R 2 o

Cl -

...

Embodiment 2

[0062] A kind of cement that utilizes phosphorus slag to produce high-quality and high-volume phosphorus slag, the cement includes the following ingredients in parts by weight:

[0063] 55 parts of clinker;

[0064] Mixed materials: 26 parts of phosphorus slag, 5 parts of limestone, 2 parts of gypsum, 0.01 part of grinding aid.

[0065] The raw meal for producing the clinker is prepared with shale, phosphorus slag, sandstone, limestone and iron ore, and the SiO in the raw meal is adjusted with sandstone as the siliceous correcting raw material. 2 .

[0066] The raw meal contains phosphorus slag with a weight ratio of 3%, and the lime saturation coefficient of the clinker is 0.92; the silicon rate is 2.5; the tricalcium aluminate content is 8%, the free calcium oxide content is 1250g / L.

[0067] The grinding aid is triethanolamine and triisopropanolamine mixed in a weight ratio of 1:1.

[0068] The gypsum is natural dihydrate gypsum.

[0069] Described phosphorus slag com...

Embodiment 3

[0072] A kind of cement that utilizes phosphorus slag to produce high-quality and high-volume phosphorus slag, the cement includes the following ingredients in parts by weight:

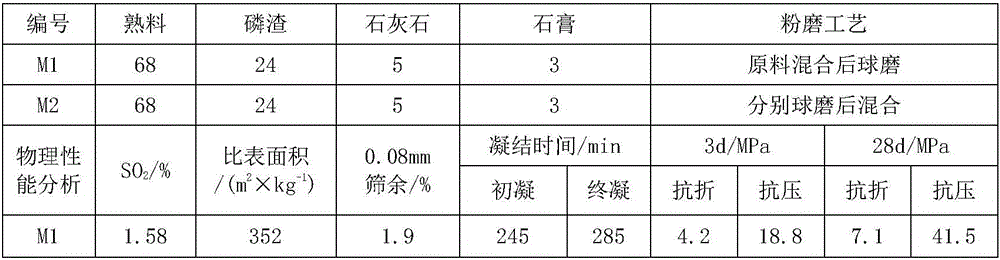

[0073] 68 parts of clinker;

[0074] Mixed materials: 39 parts of phosphorus slag, 6 parts of limestone, 4 parts of gypsum, 0.04 parts of grinding aid.

[0075] The raw meal for producing the clinker is prepared with shale, phosphorus slag, sandstone, limestone and iron ore, and the SiO in the raw meal is adjusted with sandstone as the siliceous correcting raw material. 2 .

[0076] The raw meal contains phosphorus slag with a weight ratio of 5%, and the lime saturation coefficient of the clinker is 0.96; the silicon rate is 2.7; the tricalcium aluminate content is 9%, the free calcium oxide content is 1250g / L.

[0077] The grinding aid is triethanolamine and triisopropanolamine mixed in a weight ratio of 1:1.

[0078] The gypsum is natural dihydrate gypsum.

[0079] Described phosphorus slag co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com