Method for preparing chlorophenylglycine

A technology of p-chlorophenylglycine and p-chlorobenzaldehyde, which is applied to the preparation of cyanide reaction, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of long reaction time period, difficult process control, and low product yield, etc. problems, to achieve fast response, ensure the safety of production operations, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A. Preparation of p-chlorophenylhydantoin

[0034] a) Preparation of raw materials: prepare p-chlorobenzaldehyde feed solution, 20% ammonium bicarbonate solution, 30% sodium cyanide solution and 30% sodium hydroxide solution that melt into liquid;

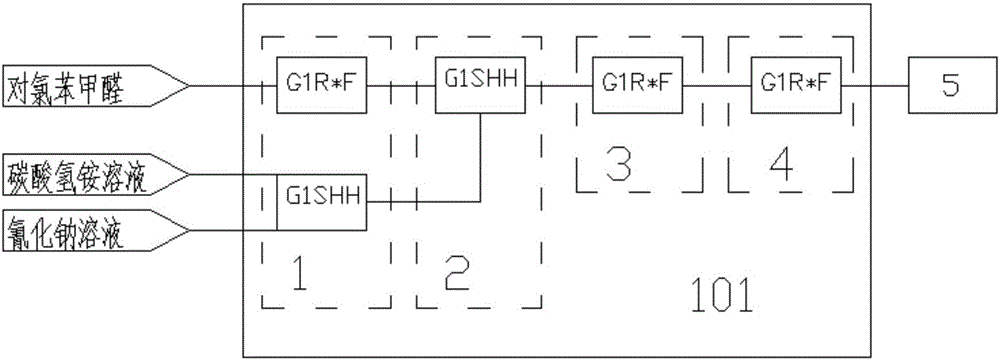

[0035] b) After the p-chlorobenzaldehyde is heated and melted into a liquid state, it is passed into the G1R*F module of the preheating zone pipeline 1 via a metering pump, the control flow is 5.0g / min, and the preheating temperature of the G1R*F module is 50℃;

[0036] The 20% ammonium bicarbonate aqueous solution and the 30% sodium cyanide solution are respectively fed into the G1SHH module of the preheating zone pipeline 1 through the metering pump to preheat and mix, and the flow rate of the 20% ammonium bicarbonate aqueous solution is controlled to 21.0g / min. The flow rate of 30% sodium cyanide solution is 5.8g / min, and the preheating temperature of G1SHH module is 50℃;

[0037] c) The p-chlorobenzaldehyde feed solution preheat...

Embodiment 2

[0047] A. Preparation of p-chlorophenylhydantoin

[0048] a) Preparation of raw materials: prepare p-chlorobenzaldehyde feed solution, 20% ammonium bicarbonate solution, 30% sodium cyanide solution and 30% sodium hydroxide solution that melt into liquid;

[0049] b) After the p-chlorobenzaldehyde is heated and melted into a liquid state, it is passed into the G1R*F module of the preheating zone pipeline 1 through a metering pump, the control flow is 7.5g / min, and the preheating temperature of the G1R*F module is 55℃;

[0050] The 20% ammonium bicarbonate aqueous solution and the 30% sodium cyanide solution are respectively fed into the G1SHH module of the preheating zone pipeline 1 through the metering pump to preheat and mix, and the flow rate of the 20% ammonium bicarbonate aqueous solution is controlled to 35.9g / min. The flow rate of 30% sodium cyanide solution is 11.3g / min, and the preheating temperature of G1SHH is 55℃;

[0051] c) The p-chlorobenzaldehyde feed solution preheated...

Embodiment 3

[0061] A. Preparation of p-chlorophenylhydantoin

[0062] a) Preparation of raw materials: preparation of p-chlorobenzaldehyde feed solution, 20% ammonium bicarbonate solution, 30% sodium cyanide solution and 30% sodium hydroxide solution that melt into liquid;

[0063] b) After the p-chlorobenzaldehyde is heated and melted into a liquid state, it is fed into the G1R*F module in the preheating zone pipeline 1 via a metering pump, and the control flow is 10.0g / min, and the preheating temperature of the G1R*F module is 60℃;

[0064] Pass the 20% ammonium bicarbonate aqueous solution and 30% sodium cyanide solution through the metering pump into the G1SHH module in the preheating zone pipeline 1 to preheat and mix, and control the flow rate of the 20% ammonium bicarbonate aqueous solution to 56.3g / min , The flow rate of 30% sodium cyanide solution is 17.4g / min, and the preheating temperature of G1SHH is 60℃;

[0065] c) The p-chlorobenzaldehyde feed solution preheated in step a) and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com