Method for preparing potassium oxonate

A technology of oteracil potassium and potassium iodide, which is applied in the field of chemical synthesis, can solve the problems of non-compliance with medicinal requirements, low product purity, high production cost, etc., and achieve the effects of favorable reaction, high product yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

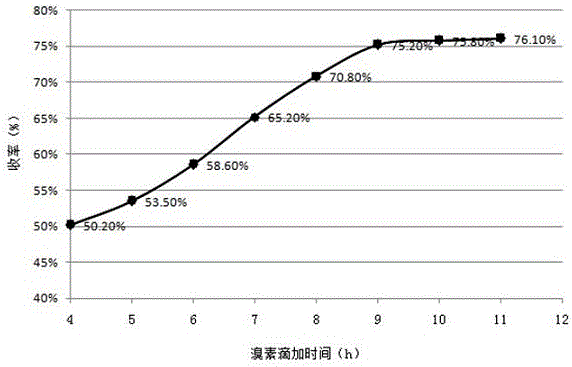

[0025] Dissolve 3.2Kg of potassium hydroxide in 11.4L of water, add it into a 20L reaction kettle, cool down to 0-5°C, add 46g of potassium iodide, add 0.9kg of allantoin in batches, stir to dissolve, and control the temperature at 0-5°C It takes 9 hours to add 1.8kg of bromine dropwise (according to the different bromine dropping time, they are respectively regarded as the 1-8 group). Bursulin figure 1

[0026] group

[0027] . figure 1 It is the relationship diagram between reaction temperature and yield in the embodiment of the present invention. Depend on figure 1 As can be seen, along with the increase of the bromine dripping time, the yield of oteracil potassium increases, and when the bromine dripping time is 9 hours, the yield can increase to 75.2%, and then prolong the dripping time later, the yield increases Not obvious.

Embodiment 2

[0029] Dissolve 3.2Kg of potassium hydroxide in 12.8L of water, add it into a 20L reaction kettle, cool down to 0-5°C, add 48g of potassium iodide, add 1.0kg of allantoin in batches, stir to dissolve, and control the temperature at 0-5°C It takes 9 hours to add 2.0kg bromine dropwise. After the dropwise addition, stir at 0-5°C for 1 hour, raise the temperature to 20-25°C and react for 20 hours. HPLC detects that allantoin is <0.6%, cool down to 0-5°C, and add acetic acid dropwise to adjust pH to 5, filtered, washed with 3L of water at 0-5°C, washed with 1L of ethanol at room temperature, and dried by blast at room temperature to obtain 928.36g of white crystalline solid with a yield of 75.21% and a purity of 99.6%.

Embodiment 3

[0031] Dissolve 3.2Kg of potassium hydroxide in 9.6L of water, add it into a 20L reaction kettle, cool down to 0-5°C, add 38g of potassium iodide, add 0.8kg of allantoin in batches, stir to dissolve, and control the temperature at 0-5°C It takes 9 hours to add 1.6kg bromine dropwise. After the dropwise addition, stir at 0-5°C for 1 hour, heat up to 20-25°C and react for 20 hours. HPLC detects that allantoin is <0.6%, cool down to 0-5°C, and add acetic acid dropwise to adjust pH to 5, filtered, washed with 3L of water at 0-5°C, washed with 1L of ethanol at room temperature, and air-dried at room temperature to obtain 712.07g of white crystalline solid with a yield of 72.1% and a purity of more than 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com