Self-reinforced profiled bar, and production method and application thereof

A profile technology, applied in the field of self-reinforced profile and its preparation, can solve the problems of PVC base material decomposition and foaming, reduce the reinforcing effect of reinforcing strips, and be vulnerable to lightning strikes, etc., and achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

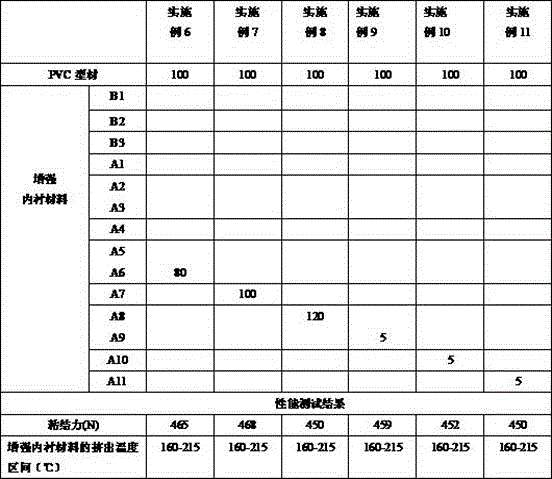

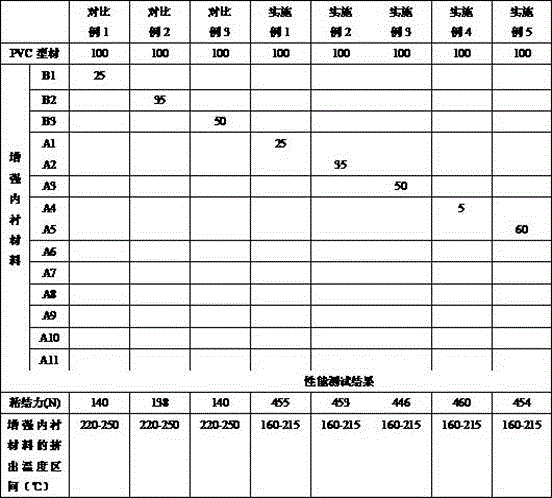

[0041] In order to better understand the present invention, the present invention will be further described through the following examples. It should be noted that the examples do not constitute a limitation to the protection scope of the present invention.

[0042] The raw materials used are as follows:

[0043] PVC profiles, PVC-EX23, made by Kingfa Technology;

[0044] AS styrene-acrylonitrile resin, SAN PN-137H, Chimei, Taiwan, China, melt flow rate 12 g / 10min;

[0045] AS styrene-acrylonitrile resin, SAN NF-5 customized; melt flow rate 5 g / 10min;

[0046]AS styrene-acrylonitrile resin, SAN NF2200, Taiwan Chemical, melt flow rate 35g / 10min; ABS resin, ABSAG10NP, Taiwan Chemical; melt flow rate 6 g / 10min;

[0047] PBT resin, PBT 1200-211M, Changchun, Taiwan, China;

[0048] ASA styrene-acrylonitrile-acrylate copolymer, ASA PW-997, Chimei, Taiwan, China; melt flow rate 5g / 10min;

[0049] Glass fiber, ECS13-4.5-534A, Tongxiang Boulder, 6~20μm in diameter.

[0050] Carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com