Low-floating-fiber high-flame-retardancy PBT (polybutylene terephthalate) material and preparation method thereof

A high flame-retardant, low-floating fiber technology, applied in the field of polymer modification, can solve the problems of insufficient flame retardancy of PBT, easy to drip when burning, and many floating fibers, and achieve excellent flame-retardant effect, low cost, and bulk density Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

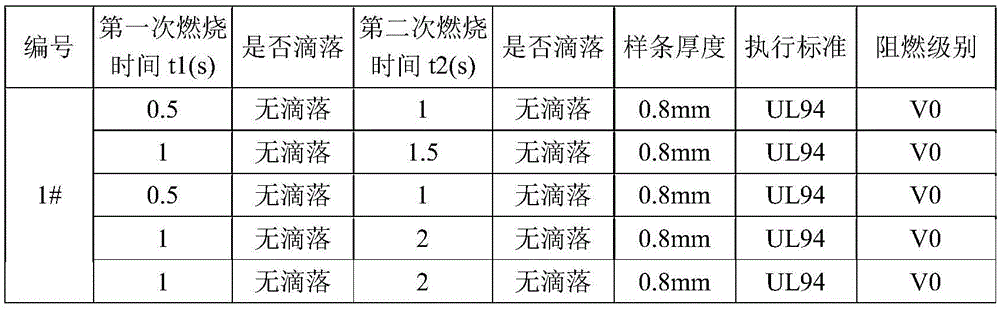

Embodiment 1

[0031] A low floating fiber high flame retardant PBT material, comprising the following raw materials in weight ratio:

[0032] PBT resin: 52 parts, flame retardant A: 12 parts, flame retardant B: 5 parts, flame retardant C: 0.2 parts, glass fiber: 27 parts, toughening agent: 4 parts, coupling agent: 0.22 parts, Anti-glass fiber exposure agent: 0.75 parts, lubricant: 0.35 parts, antioxidant: 0.26 parts.

[0033] Further, the viscosity of the PBT resin is 0.95. A low-floating fiber and high flame-retardant PBT material provided by the present invention, in order to make the glass fiber well dispersed and reduce the floating fiber, the PBT raw material selects a medium-low viscosity with an intrinsic viscosity of 0.95 PBT resin, to ensure that the material has sufficient fluidity. This resin has a low concentration of terminal carboxyl groups and low water content, making the material less prone to hygrothermal degradation during processing, while ensuring the mechanical properti...

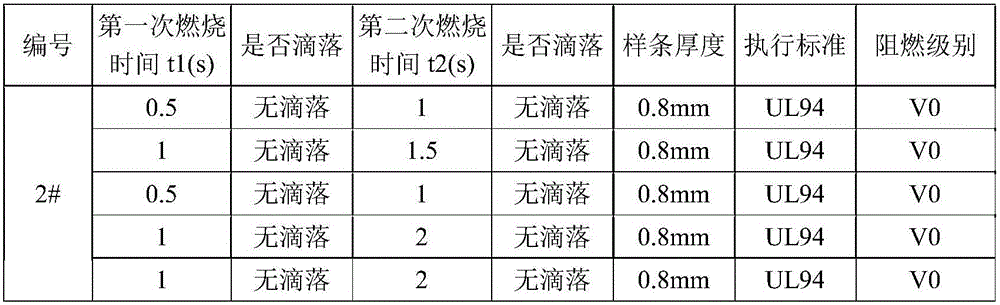

Embodiment 2

[0053] A low floating fiber high flame retardant PBT material, comprising the following raw materials in weight ratio:

[0054] PBT resin: 50 parts, flame retardant A: 13 parts, flame retardant B: 5 parts, flame retardant C: 0.2 parts, glass fiber: 27 parts, toughening agent: 5 parts, coupling agent: 0.1 parts, Anti-glass fiber exposure agent: 1 part, lubricant: 0.5 part, antioxidant: 0.1 part.

[0055] Further, the viscosity of the PBT resin is 0.86. In the low-floating fiber and high flame-retardant PBT material provided by the present invention, in order to make the glass fiber well dispersed and reduce the floating fiber, the PBT raw material selects a medium-low viscosity PBT with an intrinsic viscosity of 0.86. Resin, to ensure that the material has sufficient fluidity. This resin has a low concentration of terminal carboxyl groups and low water content, making the material less prone to hygrothermal degradation during processing, while ensuring the mechanical propertie...

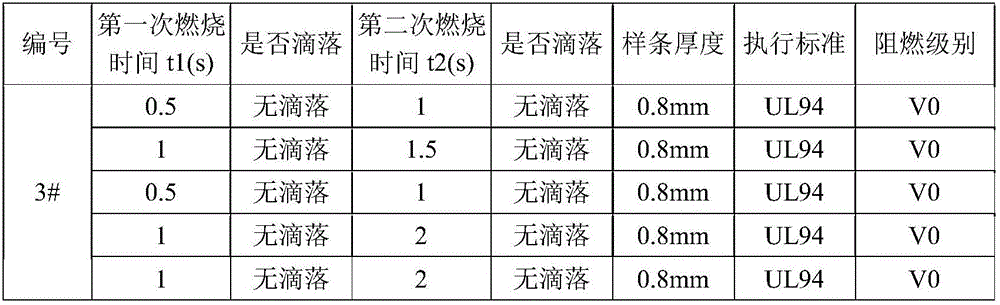

Embodiment 3

[0075] A low floating fiber high flame retardant PBT material, comprising the following raw materials in weight ratio:

[0076] PBT resin: 45 parts, flame retardant A: 13 parts, flame retardant B: 6 parts, flame retardant C: 0.3 parts, glass fiber: 30 parts, toughening agent: 6 parts, coupling agent: 0.3 parts, Anti-glass fiber exposure agent: 0.5 parts, lubricant: 0.2 parts, antioxidant: 0.5 parts.

[0077] Further, the viscosity of the PBT resin is 1.05. In the low-floating fiber and high flame-retardant PBT material provided by the present invention, in order to make the glass fiber well dispersed and reduce the floating fiber, the PBT raw material selects a medium-low viscosity PBT with an intrinsic viscosity of 1.05. Resin, to ensure that the material has sufficient fluidity. This resin has a low concentration of terminal carboxyl groups and low water content, making the material less prone to hygrothermal degradation during processing, while ensuring the mechanical prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com