Silver salt doped silver conductive adhesive, as well as preparation method and application thereof

A technology of conductive silver glue and silver salt, applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of low conductivity, weak adhesion, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

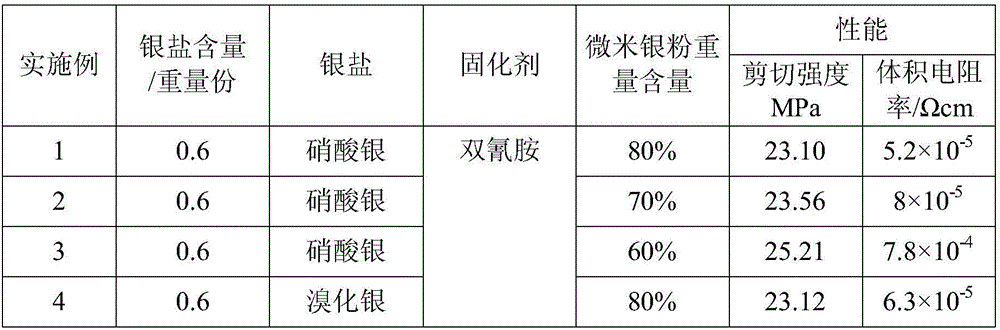

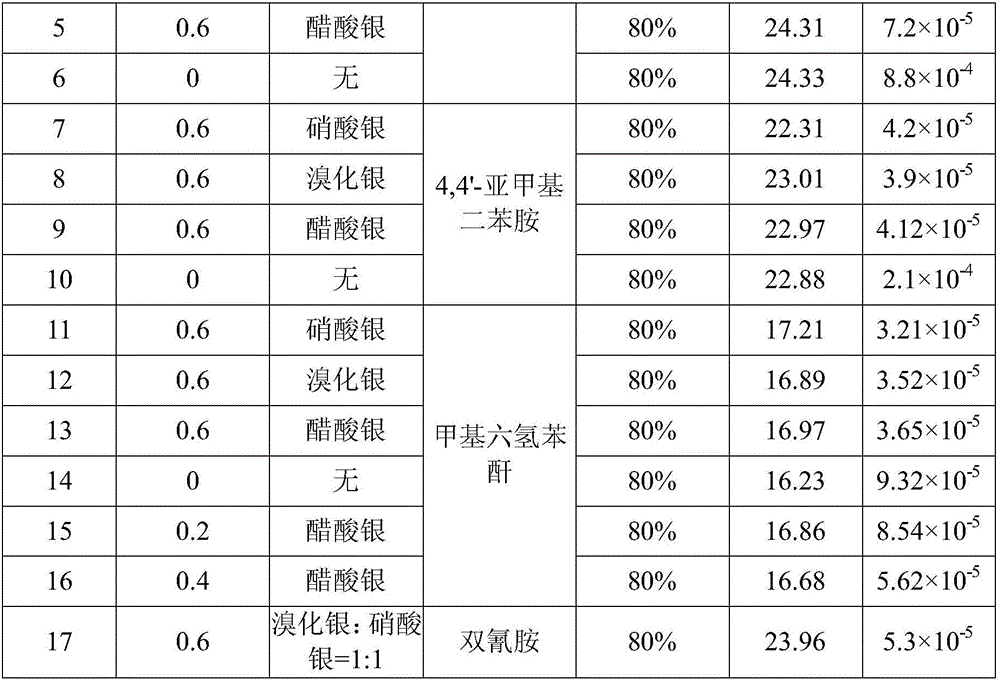

Embodiment 1

[0099] This embodiment provides a conductive silver glue doped with silver salt, which is prepared from the following raw materials:

[0100] 0.6 parts by weight of silver salt (silver nitrate);

[0101] 80 parts by weight of micron silver powder (mixing flaky rod-shaped silver powder, 5 microns of average particle diameter);

[0102] Epoxy resin (Shell bisphenol A type epoxy resin 828E) 17 parts by weight;

[0103] 1 part by weight of curing agent (dicyandiamide);

[0104] Accelerator (1-cyanoethyl-2-ethyl-4-methylimidazole) 0.1 parts by weight;

[0105] 0.1 parts by weight of coupling agent (KH-560);

[0106] Diluent (1,4-butanediol diglycidyl ether) 1.15 parts by weight;

[0107] Anti-precipitation agent (fumed silica) 0.05 parts by weight;

[0108] The preparation method of the above-mentioned conductive silver glue doped with silver salt comprises the following steps:

[0109] (1) Silver nitrate is filled in the epoxy resin according to the ratio, stirred and ground...

Embodiment 2

[0113] This embodiment provides a conductive silver glue doped with silver salt, which is prepared from the following raw materials:

[0114] 0.6 parts by weight of silver salt (silver nitrate);

[0115] 70 parts by weight of micron silver powder (mixing flaky rod-shaped silver powder, 5 microns of average particle diameter);

[0116] Epoxy resin (Shell bisphenol A type epoxy resin 828E) 25.0 parts by weight;

[0117] 1.4 parts by weight of curing agent (dicyandiamide);

[0118] Accelerator (1-cyanoethyl-2-ethyl-4-methylimidazole) 0.15 parts by weight;

[0119] 0.15 parts by weight of coupling agent (KH-560);

[0120] Diluent (1,4-butanediol diglycidyl ether) 2.63 parts by weight;

[0121] Anti-precipitation agent (fumed silica) 0.075 parts by weight;

[0122] The preparation method of the above-mentioned conductive silver glue doped with silver salt comprises the following steps:

[0123] (1) Silver nitrate is filled in the epoxy resin according to the ratio, stirred an...

Embodiment 3

[0127] This embodiment provides a conductive silver glue doped with silver salt, which is prepared from the following raw materials:

[0128] 0.6 parts by weight of silver salt (silver nitrate);

[0129] Micron silver powder (mixed flake rod-shaped silver powder, average particle diameter 5 microns) 60 parts by weight;

[0130] Epoxy resin (Shell bisphenol A type epoxy resin 828E) 34 parts by weight;

[0131] 2 parts by weight of curing agent (dicyandiamide);

[0132]Accelerator (1-cyanoethyl-2-ethyl-4-methylimidazole) 0.2 parts by weight;

[0133] 0.2 parts by weight of coupling agent (KH-560);

[0134] Diluent (1,4-butanediol diglycidyl ether) 2.9 parts by weight;

[0135] 0.1 parts by weight of anti-precipitation agent (fumed silica);

[0136] The preparation method of the above-mentioned conductive silver glue doped with silver salt comprises the following steps:

[0137] (1) Silver nitrate is filled in the epoxy resin according to the ratio, stirred and ground, so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com