Indium tin oxide film, preparing method thereof, array substrate comprising indium tin oxide film and display device

A technology of indium tin oxide and indium oxide, which is applied in semiconductor/solid-state device manufacturing, instruments, nonlinear optics, etc., can solve the problem that the probability of target re-use is negligible, reduce the service life of magnetron sputtering equipment, and cannot effectively guarantee Equipment loss and other issues, to achieve the effect of improving target utilization, shortening the development cycle, and simple and convenient control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

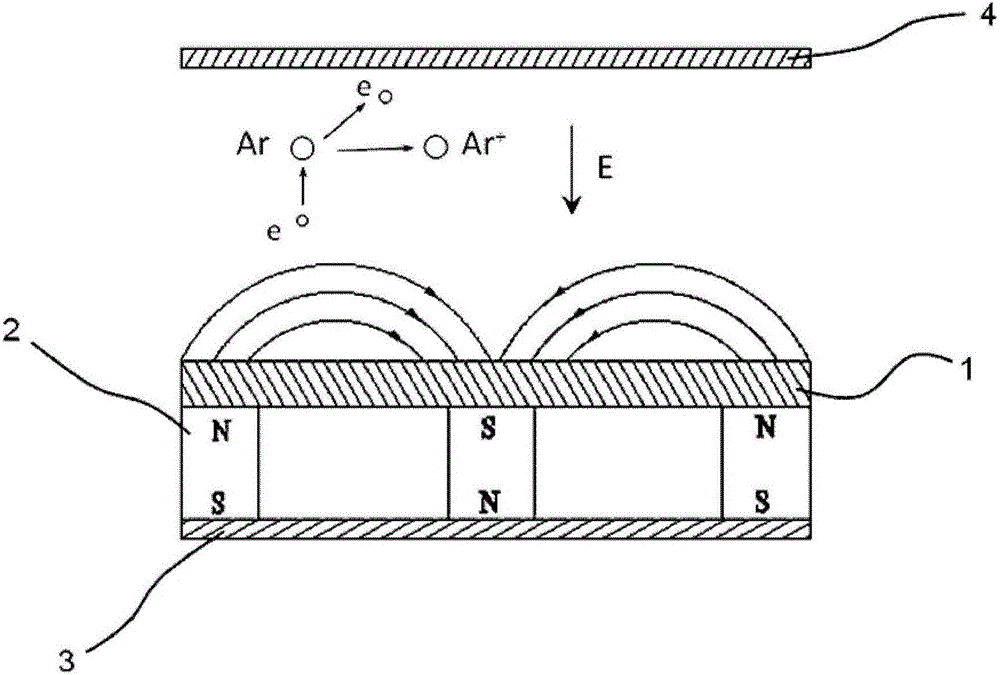

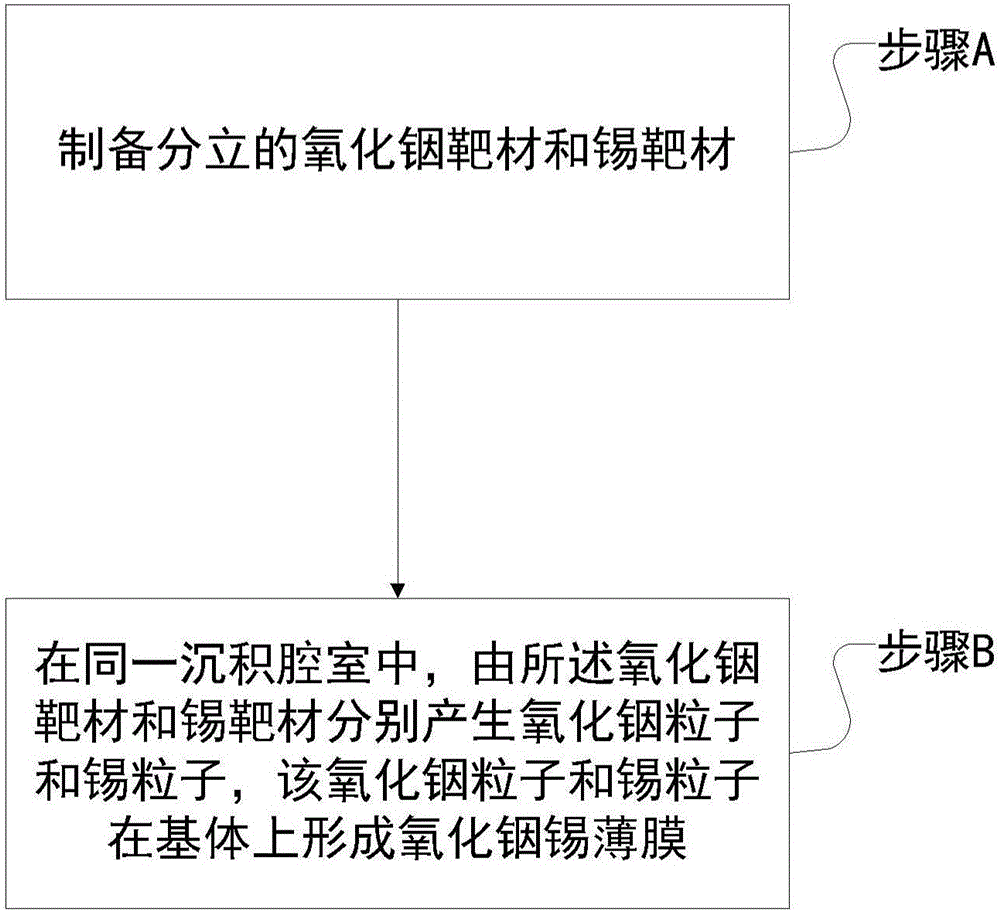

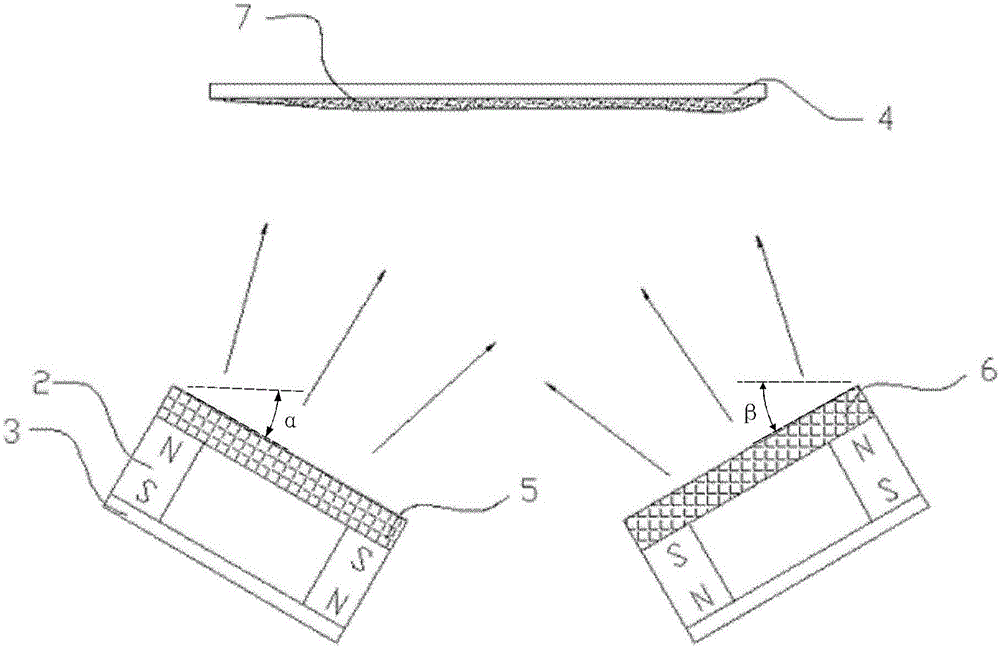

[0045] In the following, the technical solutions of the present invention will be further described in detail through embodiments and in conjunction with the drawings. In the specification, the same or similar reference numerals indicate the same or similar components. It should be noted that the following drawings are simplified schematic diagrams. The number, shape, and size of the components in the drawings can be changed at will according to actual implementation conditions, and the layout of the components can be more complicated. The present invention can also be implemented or applied through other different specific embodiments, and various details in this specification can also be based on different viewpoints and applications, and various modifications and changes can be made without departing from the spirit of the present invention.

[0046] According to the overall inventive concept of the present invention, a method for preparing an indium tin oxide thin film is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com