Heat storage type combustion device and method for processing dust-containing VOC waste gas

An incineration device and regenerative technology, which is applied in the combustion method, incinerator, combustion type, etc., can solve the problems of heat exchange deterioration, over-temperature burning of the regenerative body, blockage of small holes, etc., and achieve the effect of high-efficiency and energy-saving treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

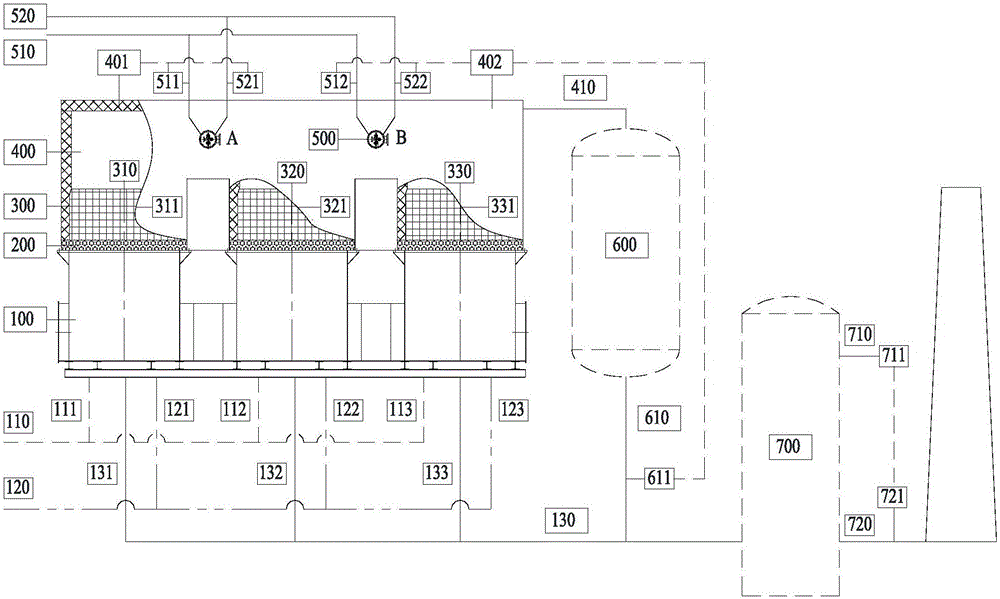

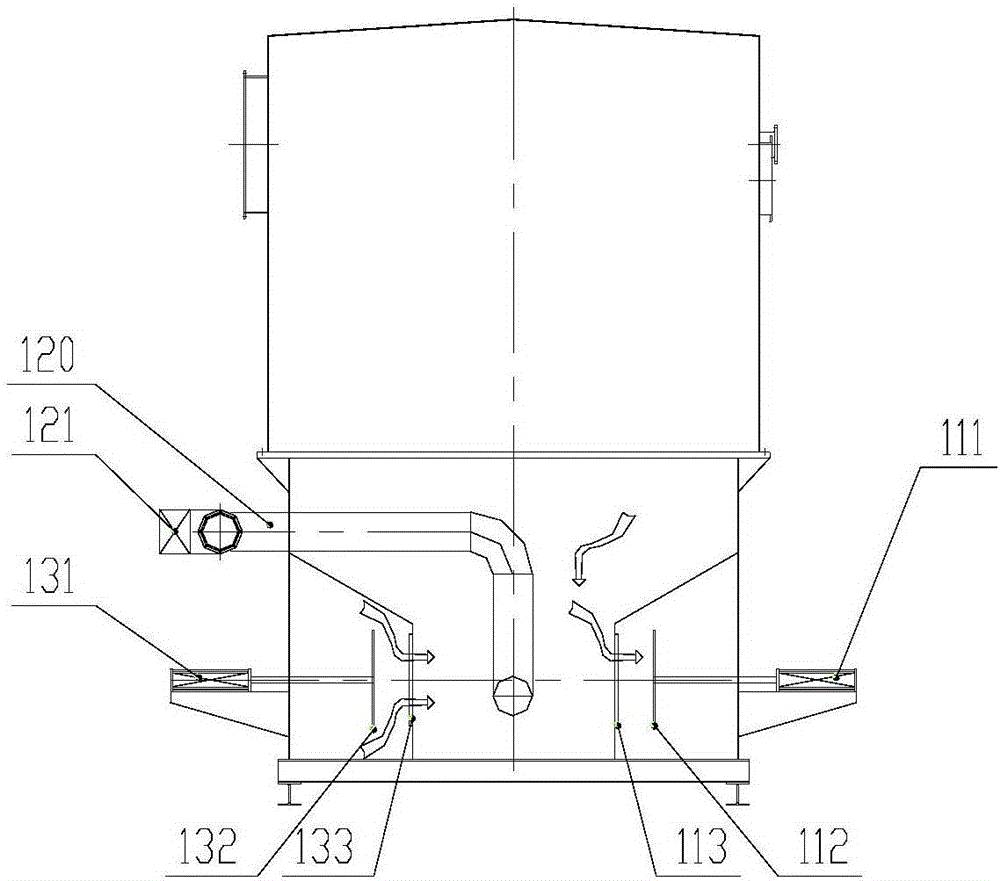

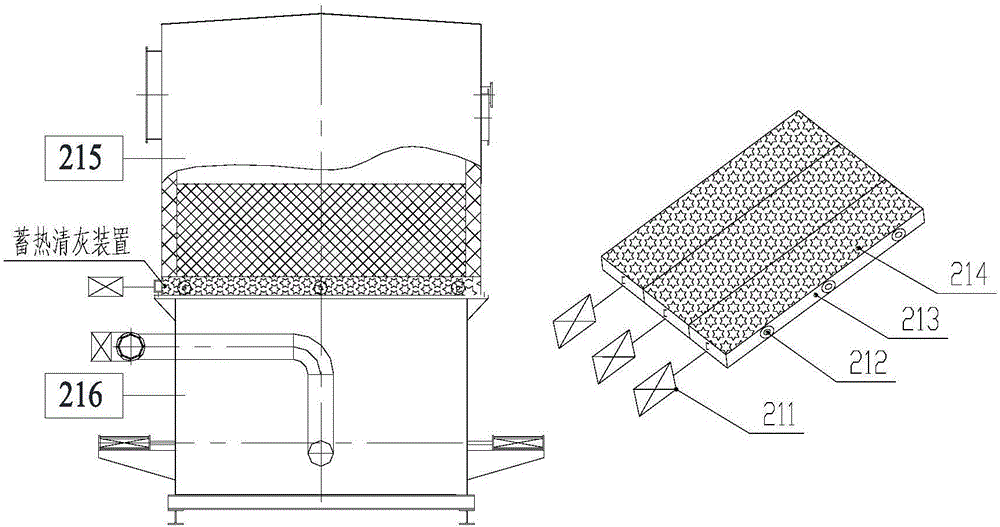

[0023] Such as figure 1 As shown, a regenerative incineration device for treating dusty VOC waste gas according to the present invention includes a linkage valve combination 100, a regenerative ash cleaning device 200, a regenerator 300, an oxidation incinerator 400, a burner 500, Waste heat boiler 600 and quench absorption device 700 .

[0024]The upper part of the regenerator 300 is a connected oxidation incineration chamber 400, and the lower part of the regenerator 300 is arranged with a heat storage and ash cleaning device 200. The regenerator 300 is connected to the waste gas pipeline 110, the reverse blowing pipeline 120 and the flue gas through the linkage valve combination 100. Pipeline 130; two burners 500 for combustion are arranged on the oxidation incineration chamber 400.

[0025] The regenerator 300 includes the first regenerator 310, the second regenerator 320 and the third regenerator 330, and the same linkage valve combination 100 is distributed under each r...

Embodiment 2

[0031] The regenerative incineration method for treating dust-containing VOC waste gas using the device described in Example 1 includes the following steps: the VOC waste gas contains harmful gases such as toluene, xylene, sulfur-containing compounds, and a large amount of dust, and in the operating condition Large fluctuations in composition and flow rate, resulting in large fluctuations in calorific value, the design waste gas treatment capacity is 30000Nm 3 / h.

[0032] First, the fresh air blower is started to pre-purge the regenerator 300 and the oxidation incineration chamber 400 for three minutes, and the residual waste gas in the incineration device is discharged; the burner 500 is started to ignite and heat up to 850-950°C (for example: 850°C, 900°C or 950°C), switch to work mode:

[0033] In the first step, the exhaust gas is preheated to a higher temperature of 800-900°C (for example: 800°C, 850°C or 900°C) through the heat storage bin 1 310, and then enters the ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com