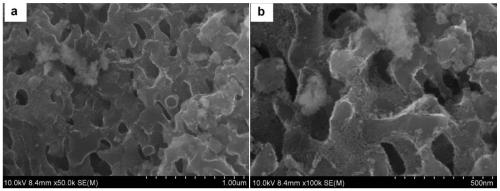

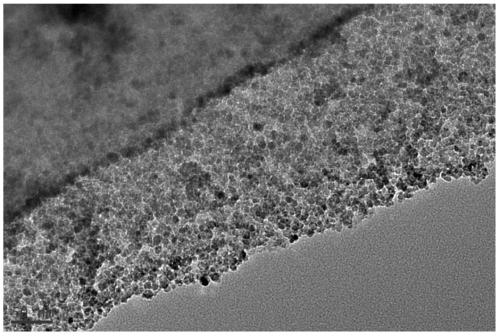

Porous carbon-supported trimanganese tetraoxide nanoparticle composite material and preparation method thereof

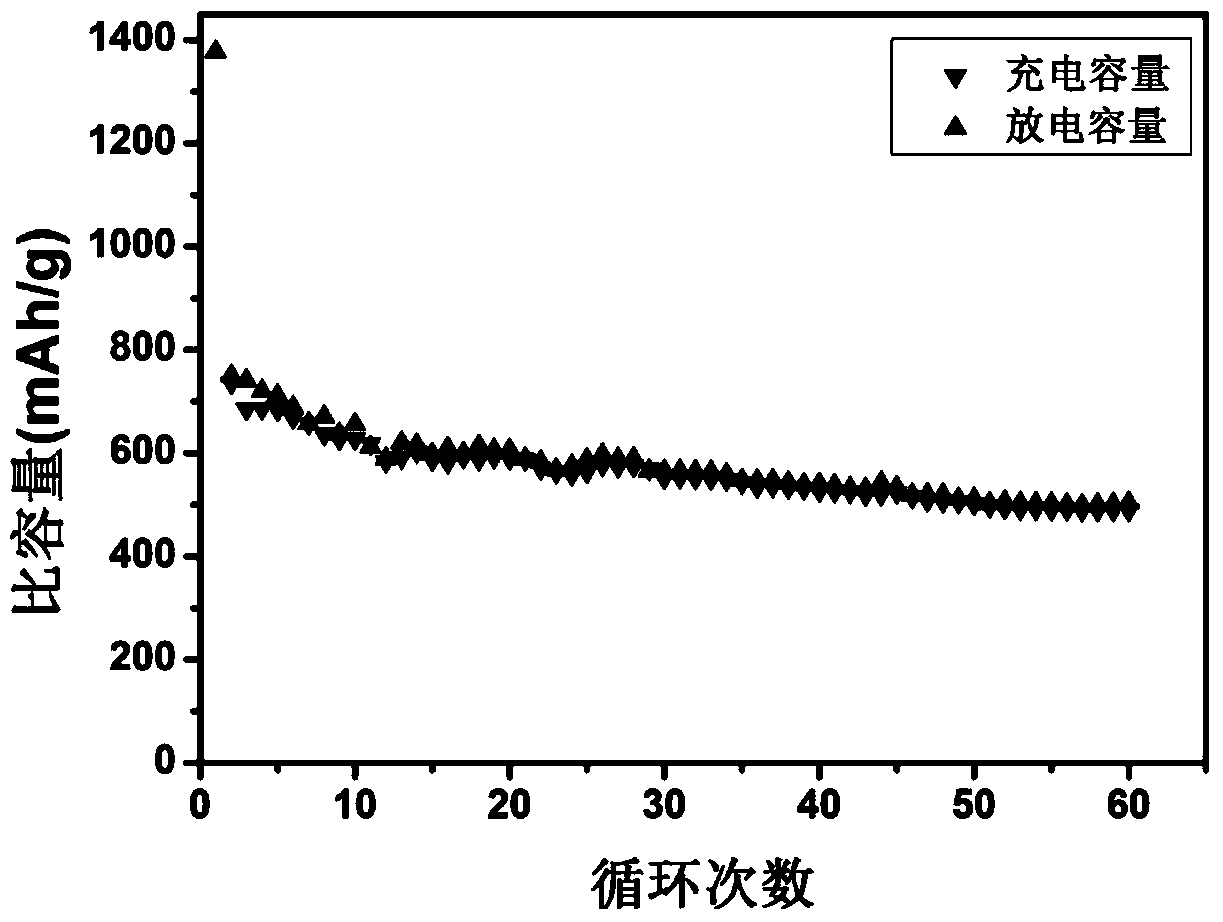

A technology of manganese tetroxide nanometers and manganese tetroxide particles is applied in the fields of material synthesis and electrochemistry to achieve the effects of improving cycle performance and charge-discharge performance, low cost, and suppressing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a porous carbon-supported manganese tetraoxide nanoparticle composite material and a preparation method thereof. The porous carbon-supported manganese tetraoxide nanoparticle composite material includes nano-manganese tetraoxide with a weight percentage content of 50%. Manganese particles and a three-dimensional porous carbon material support with a content of 50% by weight. Its preparation steps are as follows:

[0037] 1. Take 200g ginkgo leaves with electronic balance and treat with 2mol / L concentrated hydrochloric acid for 12h under magnetic stirring;

[0038] 2. After filtering the above materials, wash them three times with ethanol and water respectively, and dry them;

[0039] 3. Treat the product at 700°C for 240 minutes to complete carbonization and obtain a porous carbon scaffold;

[0040] 4. Ball mill the porous carbon support material, adopt wet ball milling, add acetone, rotate at a speed of 400r / min, ball mill for 90min in total,...

Embodiment 2

[0051] This embodiment provides a porous carbon-supported manganese tetraoxide nanoparticle composite material and a preparation method thereof. The porous carbon-supported manganese tetraoxide nanoparticle composite material includes nano-manganese tetraoxide with a content of 80% by weight. Manganese particles and a three-dimensional porous carbon material support with a content of 20% by weight. Its preparation steps are as follows:

[0052] 1. Adopt electronic balance to take the ginkgo leaf of 200g and adopt shearing machine to process with the concentrated hydrochloric acid of 2mol / L under magnetic stirring for 12h;

[0053] 2. After filtering the above materials, wash them three times with ethanol and water respectively, and dry them;

[0054] 3. Treat the product at 1000°C for 360 minutes to complete carbonization and obtain a porous carbon scaffold;

[0055] 4. Ball mill the porous carbon support material, adopt wet ball milling, add acetone, rotate at a speed of 40...

Embodiment 3

[0063] This embodiment provides a porous carbon-supported manganese tetraoxide nanoparticle composite material and a preparation method thereof. The porous carbon-supported manganese tetraoxide nanoparticle composite material includes nano-manganese tetraoxide with a weight percentage content of 65%. Manganese particles and a three-dimensional porous carbon material support with a content of 35% by weight. Its preparation steps are as follows:

[0064] 1. Adopt electronic balance to take the ginkgo leaf of 200g and adopt shearing machine to process with the concentrated hydrochloric acid of 2mol / L under magnetic stirring for 12h;

[0065] 2. After filtering the above materials, wash them three times with ethanol and water respectively, and dry them;

[0066] 3. Treat the product at 850°C for 300 minutes to complete carbonization and obtain a porous carbon scaffold;

[0067] 4. Ball mill the porous carbon support material, adopt wet ball milling, add acetone, rotate at a spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com