A kind of preparation method of heterogeneous fenton catalyst fe3c/c composite material

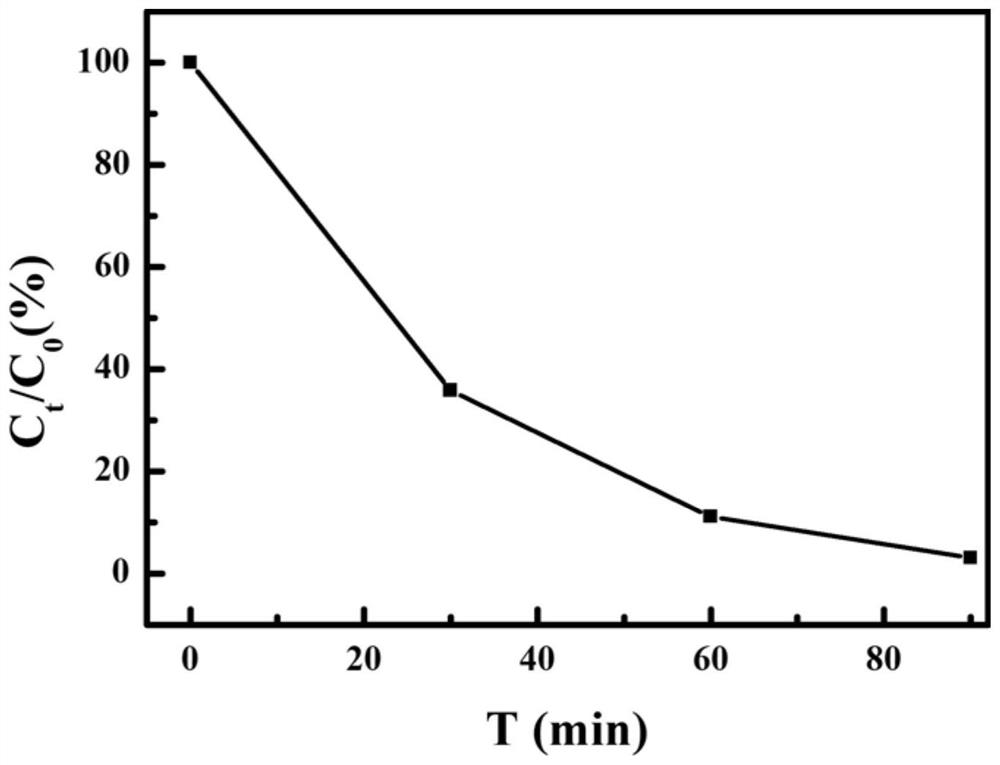

A composite material and catalyst technology, which is applied in the field of preparation of heterogeneous Fenton-like catalyst Fe3C/C composite materials, can solve the problems of unfavorable large-scale use, secondary pollution, equipment corrosion, etc., and achieve low cost, low equipment requirements, The effect of short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1, Fe 3 Preparation of C / C composites

[0037] Add 1g of Enteromorpha powder and 9mmol of potassium ferrate into a 100mL beaker, add 90mL of deionized water and stir evenly, place in a water bath at 80°C, stir and heat until dried to obtain the precursor powder. The precursor powder was heated to 800° C. and calcined for 2 hours in an Ar atmosphere to obtain a black powder. Transfer it to 80 mL of 1 mol / L hydrochloric acid solution, stir and wash it, wash it with deionized water until it is neutral, and dry it to obtain the final product.

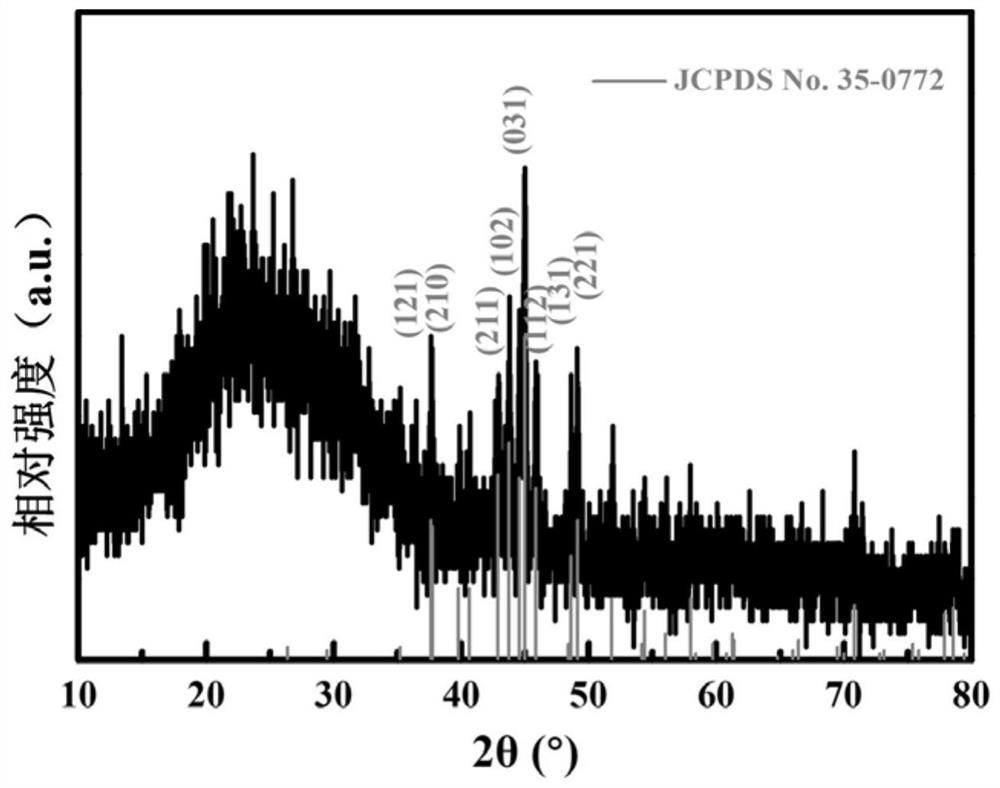

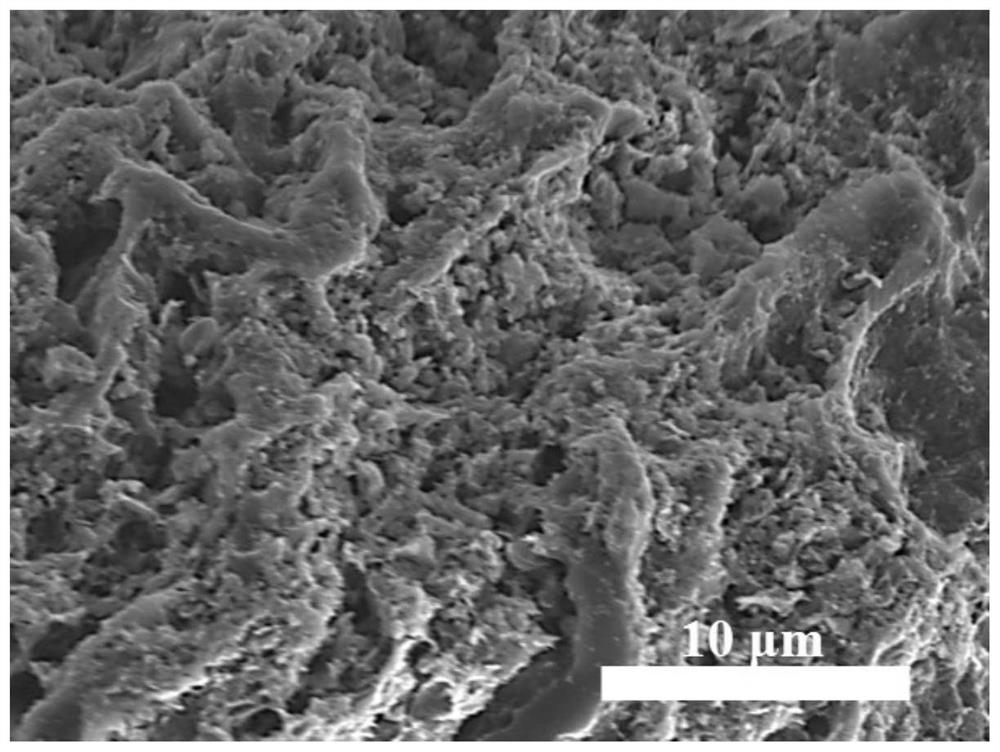

[0038] The product adopts Bruker D8ADVANCE X-ray powder diffractometer to carry out phase analysis with Cu Kα ray (wavelength scanning step speed is 0.08 ° / second), the result is as follows figure 1 shown by figure 1 It can be seen that the final product is pure phase Fe 3 C / C complexes can be used as Fenton-like catalysts, figure 2 SEM photograph of the final product.

Embodiment 2

[0039] Example 2, Fe3 Preparation of C / C composites

[0040] Add 1.2g of soybean hull powder and 9mmol of sodium ferrate into a 100mL beaker, add 90mL of deionized water and stir evenly, place in a 90°C water bath, stir and heat until dried to obtain the precursor powder. The precursor powder was heated to 700° C. and calcined for 3 hours in a nitrogen atmosphere to obtain a black powder. Transfer it to 100 mL of 0.6 mol / L hydrochloric acid solution for stirring and washing, wash with deionized water until neutral, and dry to obtain the final product.

[0041] The product was subjected to phase analysis with Cu Kα rays (wavelength scan step speed of 0.08° / sec) using a Bruker D8ADVANCE X-ray powder diffractometer, and the results showed that it was a pure phase of Fe 3 C / C complexes can be used as Fenton-like reagents.

Embodiment 3

[0042] Example 3, Fe 3 Preparation of C / C composites

[0043] Add 1.5g of bamboo leaf powder and 9mmol of potassium ferrate into a 100mL beaker, add 90mL of deionized water and stir evenly, place in an 80°C water bath, stir and heat until dried to obtain the precursor powder. The precursor powder was heated to 750° C. and calcined for 2 hours in a nitrogen atmosphere to obtain a black powder. Transfer it to 150 mL of 0.2 mol / L hydrochloric acid solution for stirring and washing, wash with deionized water until neutral, and dry to obtain the final product.

[0044] The product was subjected to phase analysis with Cu Kα rays (wavelength scan step speed of 0.08° / sec) using a Bruker D8ADVANCE X-ray powder diffractometer, and the results showed that it was a pure phase of Fe 3 C / C complexes can be used as Fenton-like reagents.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com