Method for industrially preparing braised pork

A technology for braised pork and pork belly, which is applied in the field of food processing, can solve the problems that the taste and taste cannot be unified, depend on the craftsmanship of chefs, easily cause food poisoning, etc., and achieve the effects of enhancing heat-clearing and detoxifying, improving nutrients, and improving taste and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

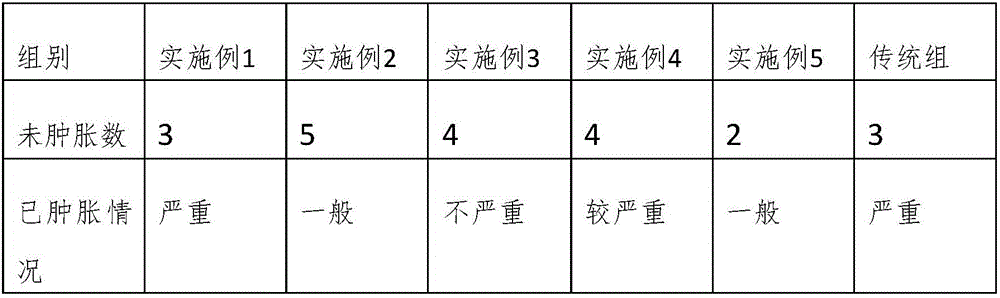

Examples

Embodiment 1

[0045] Preparation of rice wine: Mix 0.2kg of licorice and 0.4kg of winter melon, add 5L of water, extract at a temperature of 75°C, and obtain the extract for later use; steam 1.2kg of glutinous rice, mix it with 0.3kg of banana and the extract, add 12g of yeast and 60g of beer were sealed and fermented at a temperature of 20°C for 7 days, wherein during the sealed fermentation time, deflation was performed every 1d to obtain rice wine;

[0046] Preparation of marinade: Heat 1.35kg of soy sauce to 100°C, add 1.35kg of denatured starch and mix for 3 minutes, cool until there is no obvious steam, add 1.35kg of salt and stir evenly, cool to room temperature, add it to 4.05kg of rice wine, seal and let stand After 18 hours, add 20.25 kg of water and stir evenly to obtain the pickle preparation;

[0047] Preparation of braised sauce: mix 280 g of bagasse, 100 g of actinolite, and 140 g of dodder seed, and then extract with water. The amount of water added is 300 mL. The extraction...

Embodiment 2

[0050]Preparation of rice wine: Mix 0.15kg of licorice and 0.2kg of winter melon, add 3L of water, extract at a temperature of 90°C, and obtain the extract for later use; steam 1kg of glutinous rice, mix it with 0.4kg of banana and the extract, and add yeast 8g of bacteria and 90g of beer were sealed and fermented at a temperature of 25°C for 7 days, wherein during the sealed fermentation time, deflation was performed every 1d to obtain rice wine;

[0051] Preparation of pickling preparation: Heat 1.29kg of soy sauce to 85°C, add 1.29kg of denatured starch and mix for 2 minutes, cool until there is no obvious steam, add 1.29kg of salt and stir evenly, cool to room temperature, add it to 3.87kg of rice wine, seal and let stand After 12 hours, add 19.35 kg of water and stir evenly to obtain the pickle preparation;

[0052] Preparation of braised sauce: mix 350 g of bagasse, 70 g of actinolite, and 120 g of dodder seed, and then extract with water. The amount of water added is 25...

Embodiment 3

[0055] Preparation of rice wine: mix 0.3kg of licorice and 0.5kg of winter melon, add 3.5L of water, extract at a temperature of 70°C, and obtain the extract for later use; steam 1.5kg of glutinous rice, and mix it with 0.35kg of banana and the extract evenly. Add 18g of yeast and 70g of beer, and seal and ferment for 7 days at a temperature of 23°C. During the sealed fermentation, deflate once every 1d to obtain rice wine;

[0056] Preparation of pickling preparation: Heat 1.35kg of soy sauce to 90°C, add 1.35kg of denatured starch and mix for 5 minutes, cool until there is no obvious steam, add 1.35kg of salt and stir evenly, cool to room temperature, add it to 4.05kg of rice wine, seal and let stand After 15 hours, add 20.25 kg of water and stir evenly to obtain the pickling preparation;

[0057] Preparation of braised sauce: mix 320g of bagasse, 150g of actinolite, and 100g of dodder seed, then extract with water, add 320mL of water, the extraction temperature is 40°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com