Preparation method of chromium molybdate micron-nanometer material

A micro-nano, molybdic acid technology, applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., can solve the problems of difficult to control hydrolysis rate, less research on preparation methods, difficult to control crystal shape, etc., and achieve industrialized mass production. , the effect of easy operation and control, low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

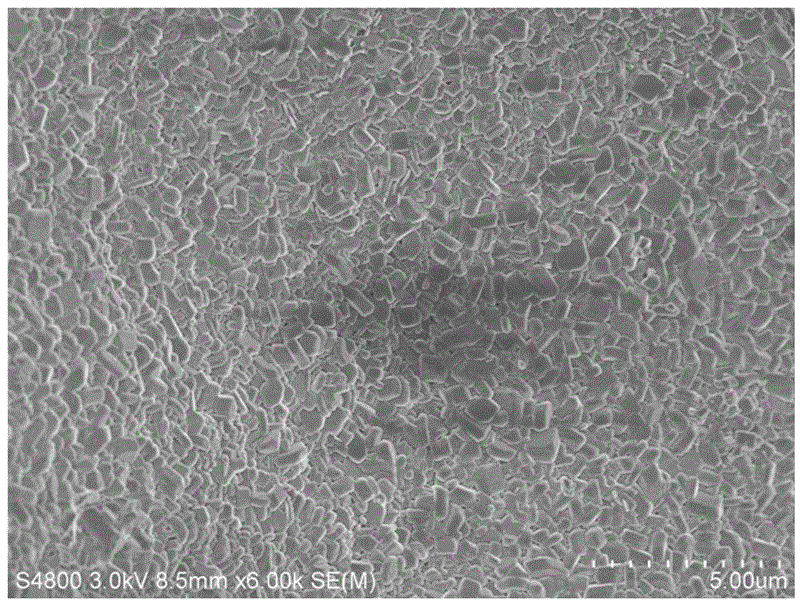

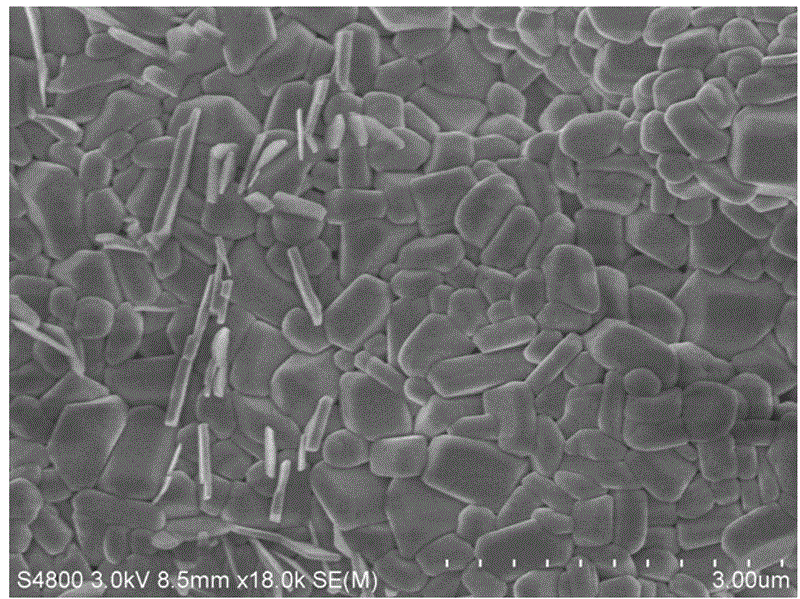

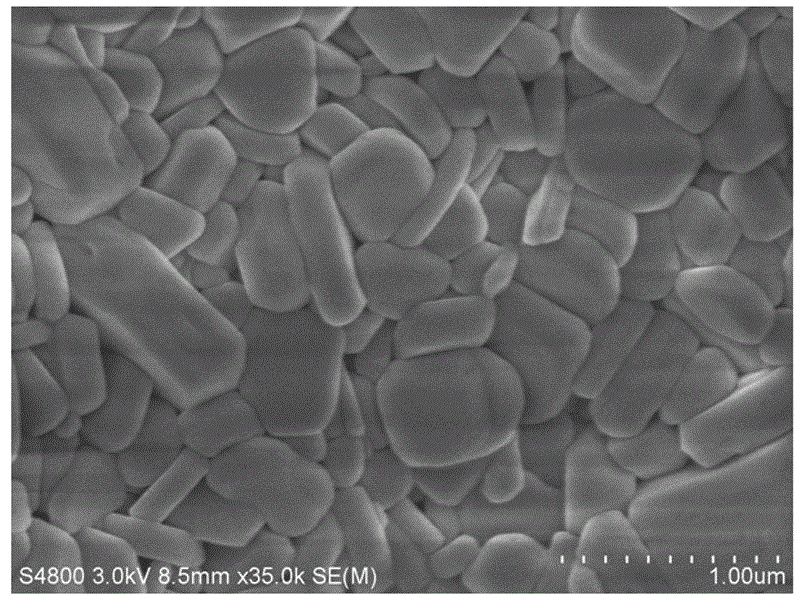

Embodiment 1

[0031] Prepare an aqueous solution of molybdic acid, chromium nitrate and oxalic acid, heat at 100°C, and evaporate water under the condition of a stirring speed of 300 rpm. The molar ratios of molybdic acid, chromium nitrate and oxalic acid are 3:2:30. The molar concentration of molybdic acid is 0.05 mol / L, and that of oxalic acid is 0.5 mol / L. After evaporating the water, carry out the cross-linking reaction, the reaction temperature is 200 °C, and the reaction time is 2 hours. After the cross-linking reaction is completed, the high-temperature reaction is carried out in the muffle furnace. The high-temperature reaction temperature is 600 °C, and the reaction time is 4 h. . After natural cooling, the target product is obtained. The product size is 0.5μm, and the yield of the product is 99.1%; the product purity is 99.5%, and the impurity content: carbon is less than 0.5%; the absorption peak.

Embodiment 2

[0033] Prepare an aqueous solution of molybdic acid, chromium nitrate and oxalic acid, heat at 100°C, and evaporate water under the condition of a stirring speed of 60 rpm. Among them, the molar ratio of molybdic acid, chromium nitrate and oxalic acid is 3:2:60. The molar concentration of molybdic acid is 0.05 mol / L, and that of oxalic acid is 0.5 mol / L. After the water was evaporated, the cross-linking reaction was carried out. The reaction temperature was 400 °C and the reaction time was 2 hours. After the cross-linking reaction was completed, the high-temperature reaction was carried out in a muffle furnace. . After natural cooling, the target product is obtained. The size of the product is 0.9 μm, and the yield of the product is 99.6%; the purity of the product is 99.7%, and the impurity content: carbon is less than 0.3%; the absorption peak.

Embodiment 3

[0035] Prepare an aqueous solution of molybdic acid, chromium nitrate and oxalic acid, heat at 100°C, and evaporate water under the condition of a stirring speed of 120 rpm. Among them, the molar ratio of molybdic acid, chromium nitrate and oxalic acid is 3:2:50. The molar concentration of molybdic acid is 0.05 mol / L, and that of oxalic acid is 0.5 mol / L. After evaporating the water, carry out the cross-linking reaction, the reaction temperature is 150 °C, and the reaction time is 4 hours. After the cross-linking reaction is completed, the high-temperature reaction is carried out in the muffle furnace. The high-temperature reaction temperature is 600 °C, and the reaction time is 4 h. . After natural cooling, the target product is obtained. The product size is 0.5μm, and the yield of the product is 99.5%; the product purity is 99.6%, and the impurity content: carbon is less than 0.4%; the absorption peak.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com