Hardening film for protecting photovoltaic glass anti-reflection layer

A technology of anti-reflection layer and photovoltaic glass, which is applied in the field of hardened film, can solve the problems of increasing thermal infrared reflection and lack of effective protection of anti-reflection layer, and achieve the effects of prolonging life, compensating for power loss, and reducing component temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

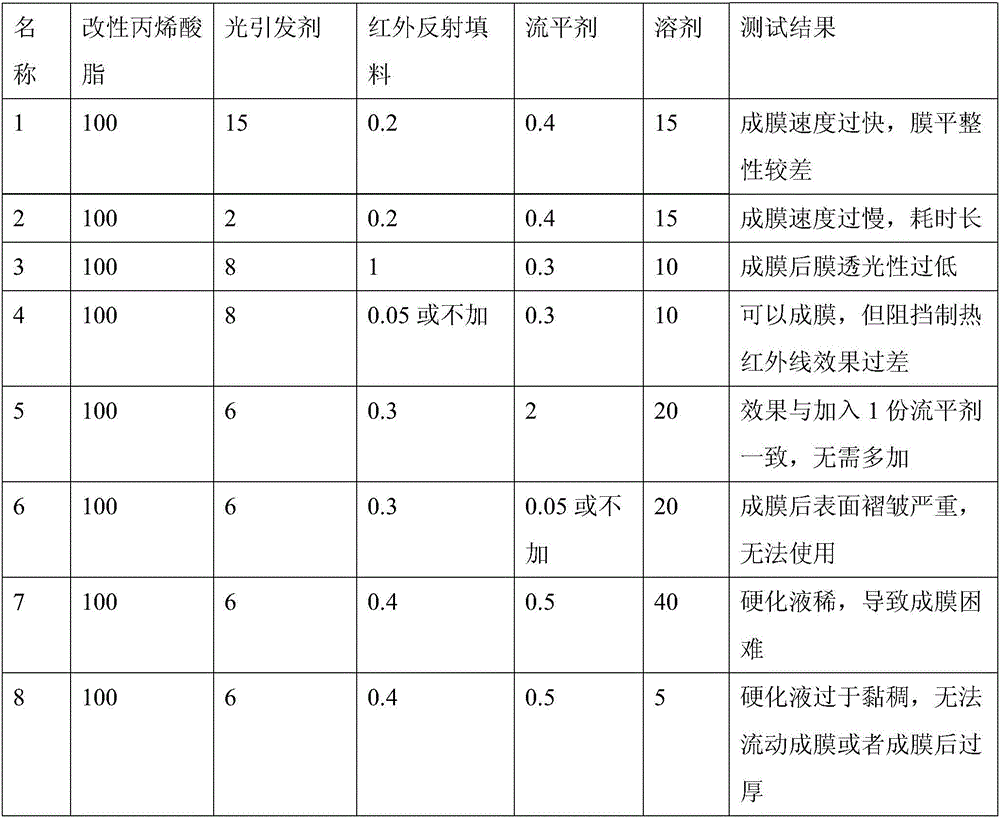

Method used

Image

Examples

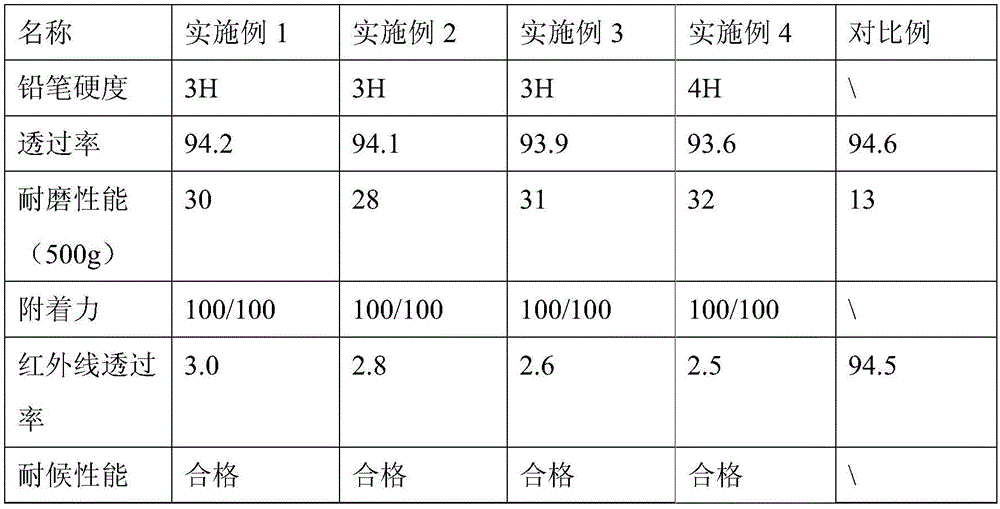

Embodiment 1

[0020] 100 mass parts of polyurethane acrylate prepolymer (6130B-80, Changxing Chemical Material Co., Ltd.), 5 mass parts of photoinitiator 1-hydroxycyclohexyl phenyl ketone (184, Changzhou Qiangli Electronic New Material Co., Ltd.), 0.1 parts by mass of silver nanoparticles (average size of 5-7 nanometers) and 0.1 parts by mass of acrylic leveling agent (EFKA3772, Efka, Netherlands) were mixed, and then 10 parts by mass of toluene (Hangzhou Chemical Reagent Co., Ltd.) was added Stir and dilute to obtain a hardening liquid paint. Then, it is coated on the anti-reflection glass substrate by wire bar coating, and then dried in an oven at 50 degrees Celsius for 2 minutes, and then the dried coating is cured by ultraviolet light. The thickness of the coating after drying is controlled to be 2um.

Embodiment 2

[0022] 100 parts by mass of epoxy acrylate (Agisyn1010, DSM Xinlimei), 7 parts by mass of photoinitiator 2-hydroxymethylphenyl propane-1-ketone (1173, Changzhou Qiangli Electronic New Materials Co., Ltd.), 0.25 parts by mass of silver nanoparticles (average size is 5-7 nanometers) and 0.3 parts by mass of organosiloxane leveling agent (EFKA3299, Efka, Netherlands) are mixed, then add 15 parts by mass of xylene (Hangzhou Chemical Reagent Co., Ltd.) was stirred and diluted to obtain a hardened liquid coating. Then, it is coated on the anti-reflection glass substrate by wire bar coating, and then dried in an oven at 50 degrees Celsius for 2 minutes, and then the dried coating is cured by ultraviolet light. The thickness of the coating after drying is controlled to be 2um.

Embodiment 3

[0024] 100 mass parts of polyester acrylate (RJ521, Asahi Kasei Corporation), 9 mass parts of photoinitiator 2,4,6-trimethylphenyl acyl diphenylphosphine oxide (D3358, Sigma Aldrich), 0.4 mass parts Parts of indium tin oxide nanoparticles (average size of 8-10 nanometers) and 0.7 parts by mass of acrylic leveling agent (EFKA3772, Efka, Netherlands) were mixed, and then 25 parts by mass of ethyl acetate (Shanghai Lingfeng Chemical Reagent Co., Ltd.) was stirred and diluted to obtain a hardened liquid coating. Then, it is coated on the anti-reflection glass substrate by wire bar coating, and then dried in an oven at 50 degrees Celsius for 2 minutes, and then the dried coating is cured by ultraviolet light. The thickness of the coating after drying is controlled to be 4um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com