Water-permeable cement concrete reinforcing agent and preparation method thereof

A technology of concrete reinforcing agent and permeable cement, which is applied in the field of permeable cement concrete reinforcing agent and its preparation, which can solve the problems of poor water permeability, running grains on the road surface, and inability to withstand high-intensity loads, so as to achieve good construction performance, improve cohesive force, Guarantee the effect of connected porosity and construction uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

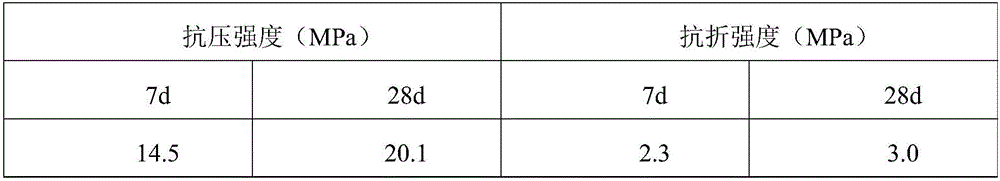

Examples

Embodiment 1

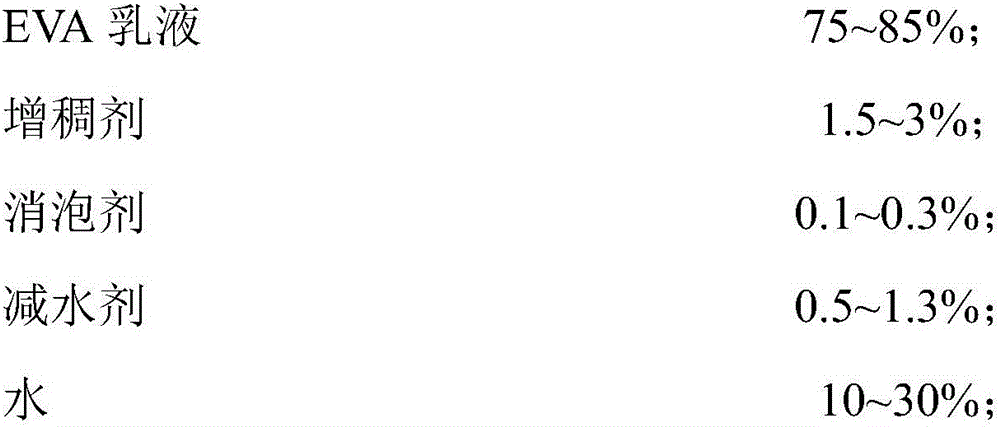

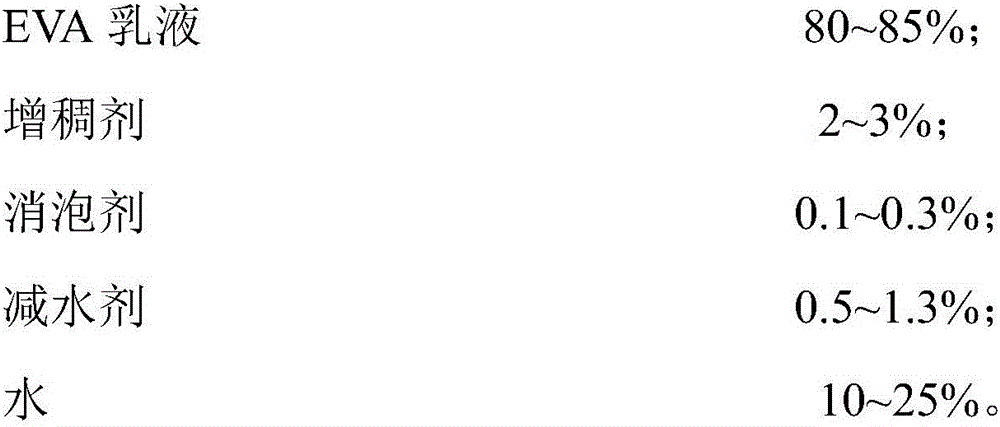

[0040] 1. The permeable cement concrete reinforcing agent is composed of the following components by weight:

[0041] 20.8% deionized water; 75% Japanese Showa AD-10 emulsion; 2% Kaiyuan chemical powder polyvinyl alcohol 2488; 1% sodium gluconate; 1% Sika polycarboxylate superplasticizer 325C; 0.2 % Dow Corning Dimethicone OFX-0193.

[0042] 2. Production method:

[0043] At a temperature of 25°C, add 20% deionized water into the production equipment according to the weight ratio, slowly add 75% Japanese Showa AD-10 emulsion under the stirring condition of 500 rpm, and stir for 15 minutes; then add 2% of Kaiyuan chemical powder polyvinyl alcohol 2488, stirred for 10 minutes; then added 1% sodium gluconate, stirred for 5 minutes; finally added 1% of Sika polycarboxylate superplasticizer 325C, 0.2% of Dow Corning Polymer Methylsiloxane OFX-0193, stirred and reacted at 25°C until the finished emulsion product is uniformly dispersed, free of bubbles and particles.

Embodiment 2

[0054] 1. The permeable cement concrete reinforcing agent is composed of the following components by weight:

[0055] 15.8% deionized water; 80% Japan Showa AD-10 emulsion; 2% Kaiyuan chemical powder polyvinyl alcohol 2488; 1% Dow TEA99 triethanolamine; 1% Sika polycarboxylate superplasticizer 325C 0.2% Dow Corning Dimethicone OFX-0193.

[0056] 2. production method is identical with embodiment 1 method.

Embodiment 3

[0062] 1. The permeable cement concrete reinforcing agent is composed of the following components by weight:

[0063] 11.8% deionized water; 85% Japanese Showa AD-10 emulsion; 2% Kaiyuan chemical powder polyvinyl alcohol 2488; 1% Sika polycarboxylate superplasticizer 325C; 0.2% Dow Corning polydimethyl Silicone OFX-0193.

[0064] 2. production method is identical with embodiment 1 method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com