Method for recovering phenylacetic acid from waste liquid in preparation of 6-aminopenicillanic acid by enzymic method

A technology for the preparation of aminopenicillanic acid and enzymatic methods, which is applied in the preparation of carboxylate salts, chemical instruments and methods, and the preparation of organic compounds. It can solve water and air pollution, difficulty in purchasing, and environmental hazards of phenylacetic acid, etc. problem, to achieve the effect of simple operation, good product quality, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

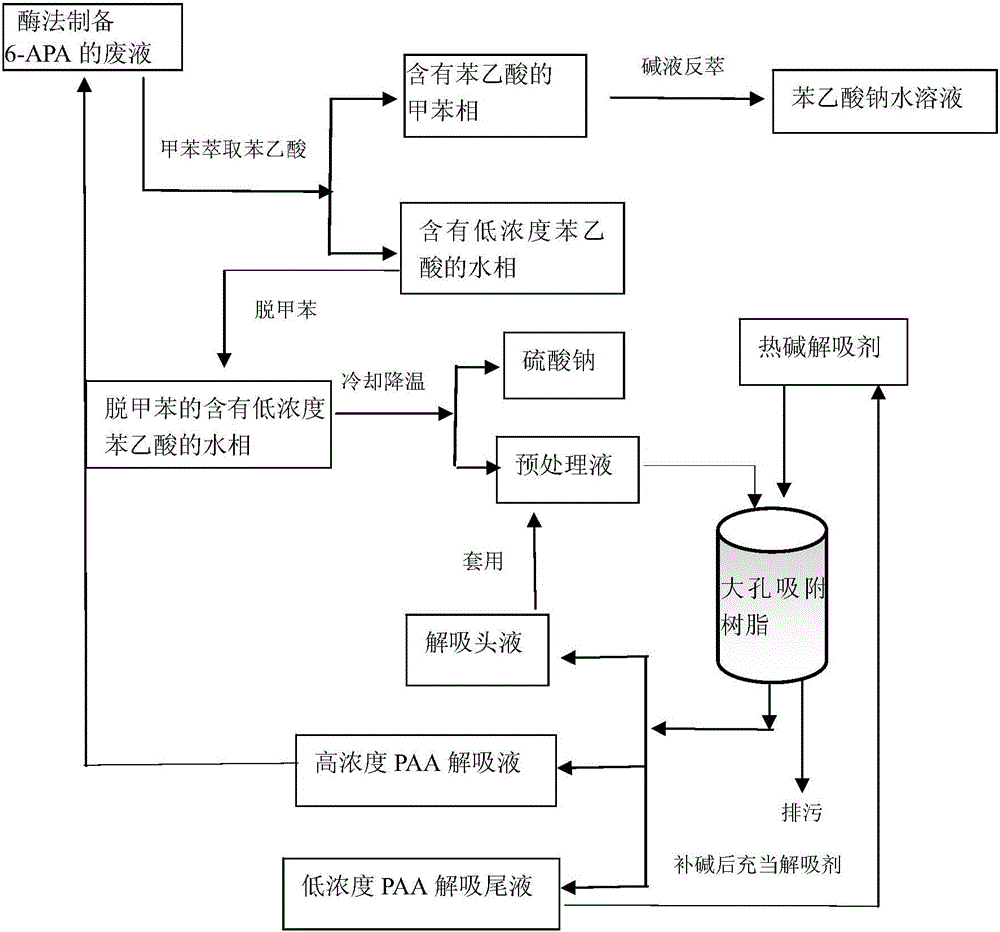

Method used

Image

Examples

Embodiment 1

[0040] Step 1: Extraction of phenylacetic acid with toluene

[0041] Get 400ml of enzymatically prepared waste liquid of 6-APA (light transmittance is 20%, appearance red-black, purity 67%), wherein phenylacetic acid content is 203mg / ml, pH value is 8.9, at temperature 35 ℃, add slowly 200ml of toluene; add 60ml of concentrated sulfuric acid to it to adjust the pH value to 1.95, control the temperature at 68°C, after the interface is clear, let it stand for stratification, that is, the toluene phase containing phenylacetic acid and the water phase containing low concentration of phenylacetic acid; separation 260 ml of toluene phase containing phenylacetic acid and 360 ml of water phase containing low concentration of phenylacetic acid (5.23 mg / ml of phenylacetic acid content) were obtained.

[0042] Step 2: preparing the sodium phenylacetate aqueous solution with few impurities

[0043] Wash 260ml of the toluene phase containing phenylacetic acid obtained in the above step 1 ...

Embodiment 2

[0053] Step 1: Extraction of phenylacetic acid with toluene

[0054] Get 400ml of the waste liquid of 6-APA prepared by enzymatic method (light transmittance is 22%, appearance red-black, purity 69%), wherein phenylacetic acid content is 195mg / ml, pH value is 8.9, at temperature 37 ℃, add slowly 200ml of toluene; then add 60ml of concentrated sulfuric acid to adjust the pH value to 1.99, and control the temperature at 68°C. After the interface is clear, let it stand for stratification, that is, the toluene phase containing phenylacetic acid and the water phase containing low-concentration phenylacetic acid; separate 260 ml of toluene phase containing phenylacetic acid and 360 ml of water phase containing low concentration of phenylacetic acid (5.67 mg / ml of phenylacetic acid content) were obtained.

[0055] Step 2: Prepare the sodium phenylacetate aqueous solution with few impurities

[0056] Wash 260ml of the toluene phase containing phenylacetic acid obtained in the above s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com