Preparation method and application of polyolefin elastomer material capable of releasing negative ions

A polyolefin elastomer and negative ion technology, applied in the coating and other directions, can solve the problems of easy hardening and yellowing, insufficient stability, etc., achieve increased functionality, avoid environmental pollution and waste of social resources, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

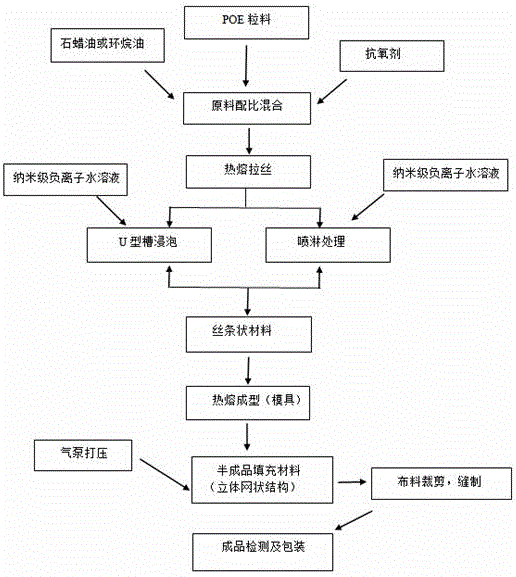

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 The preparation method of releasing anion polyolefin elastomer material, the steps are as follows:

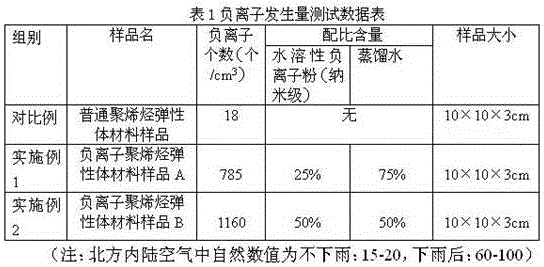

[0029] Step 1: Prepare a nano-scale negative ion aqueous solution: mix 25g of water-soluble negative ion powder and 75g of distilled water, fully stir, and prepare a nano-scale negative ion aqueous solution, then add it to a watering can or connect a spray gun for use;

[0030] Step 2: Preparation of Raw Material Ratio 2g, spare;

[0031] Step 3: Hot-melt wire drawing: The raw materials in step 2 are uniformly mixed and then added to the hot-melt wire drawing machine. Under the condition of temperature of 220°C, heat and melt into polymer, which is used as the base material to keep the polymer at a temperature of 150-150°C. In the process of 220 °C, the wire drawing is processed into a wire-like material;

[0032] Step 4: Attach the nanoscale negative ion aqueous solution: add the nanoscale negative ion aqueous solution to the filamentous material in step ...

Embodiment 2

[0034] Embodiment 2 The preparation method of releasing anion polyolefin elastomer material, the steps are as follows:

[0035] Step 1: Prepare an aqueous solution of nano-scale negative ions: mix 50 g of water-soluble negative ion powder and 50 g of distilled water, stir well, prepare a nano-scale negative ion aqueous solution, and then add it to a watering can or connect a spray gun for use;

[0036] Step 2: Preparation of Raw Material Ratio 2g, spare;

[0037] Step 3: Hot-melt wire drawing: The raw materials in step 2 are uniformly mixed and then added to the hot-melt wire drawing machine. Under the condition of temperature of 220°C, heat and melt into polymer, which is used as the base material to keep the polymer at a temperature of 150-150°C. In the process of 220 °C, the wire drawing is processed into a wire-like material;

[0038] Step 4: Attach the nanoscale negative ion aqueous solution: add the nanoscale negative ion aqueous solution to the filamentous material in...

Embodiment 3

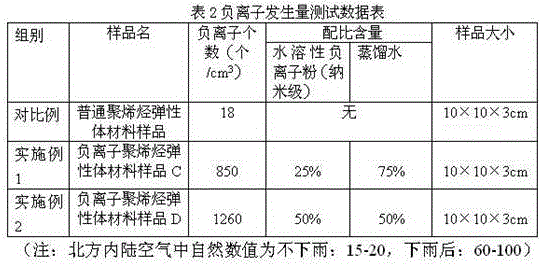

[0040] Embodiment 3 The preparation method of releasing anion polyolefin elastomer material, the steps are as follows:

[0041] Step 1: prepare a nano-scale negative ion aqueous solution: mix 25g of water-soluble negative ion powder and 75g of distilled water, stir well, prepare a nano-scale negative ion aqueous solution, and add it to a U-shaped tank for use;

[0042] Step 2: Preparation of Raw Material Ratio Ester 1g, for use;

[0043] Step 3: Hot-melt wire drawing molding: The raw materials in step 2 are uniformly mixed and then added to the hot-melt wire drawing machine. Under the condition of temperature of 260°C, heat and melt into a polymer, which is used as the base material to keep the polymer at a temperature of 150-150°C. In the process of 220 °C, the wire drawing is processed into a wire-like material;

[0044] Step 4: Attach the nano-scale negative ion aqueous solution: pass the filamentous material in the step 3 through the U-shaped groove, and make it fully an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com