Waterborne organic-inorganic hybrid anticorrosion coating and its application method

An anti-corrosion coating, organic technology, applied in anti-corrosion coatings, coatings, devices for coating liquids on surfaces, etc., can solve the problems of loss of corrosion inhibition ability, insufficient corrosion resistance, insufficient film strength, etc. The effect of layer longevity requirements, good corrosion resistance, good substrate adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

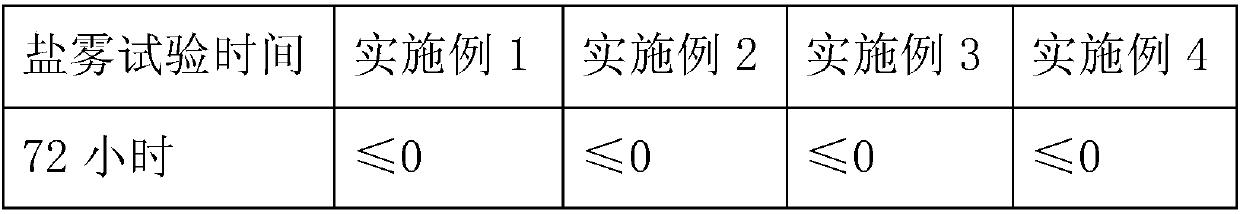

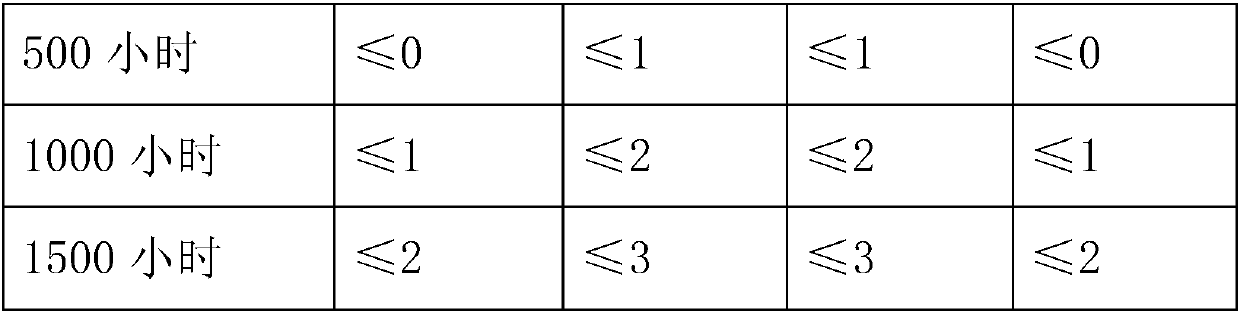

Embodiment 1

[0036] A water-based organic-inorganic hybrid anti-corrosion coating, which consists of the following components in parts by weight: 90 parts of nano-material modified acrylate composite emulsion, 10 parts of ammonium fluorozirconate, 15 parts of sodium molybdate, titanate coupling agent 10 parts, methanol 5 parts, water 32 parts, defoamer (BYK022) 1 part, PH regulator 1.8 parts, leveling agent (BYK331) 0.3 parts, curing agent 7 parts.

[0037] The preparation of nanomaterial modified acrylate composite emulsion in the present embodiment is as follows:

[0038] 1) Formula (parts by weight):

[0039] 1 part of N,N dimethylbisacrylamide, 1 part of polyethylene glycol dimethacrylate, 2 parts of acrylamide, 35 parts of styrene, 35 parts of butyl acrylate, 15 parts of hydroxyethyl methacrylate, 5 parts of acrylic acid, 1.5 parts of allyl glycidyl ether, 25 parts of methyl methacrylate, 15 parts of n-butyl methacrylate, 14 parts of dodecafluoroheptyl methacrylate, 20 parts of silic...

Embodiment 2

[0051] A water-based organic-inorganic hybrid anti-corrosion coating, which consists of the following components in parts by weight: 90 parts of nano-material modified acrylate composite emulsion, 10 parts of ammonium fluorozirconate, 15 parts of sodium molybdate, titanate coupling agent 10 parts, methanol 5 parts, water 32 parts, defoamer (BYK022) 1 part, pH regulator 2.4 parts, leveling agent (BYK331) 0.3 parts, curing agent 7 parts.

[0052] The preparation of nanomaterial modified acrylate composite emulsion in the present embodiment is as follows:

[0053] 1) Formula (parts by weight):

[0054] 1 part of N,N dimethylbisacrylamide, 1 part of polyethylene glycol dimethacrylate, 2 parts of acrylamide, 35 parts of styrene, 35 parts of butyl acrylate, 15 parts of hydroxyethyl methacrylate, 5 parts of acrylic acid, 1.5 parts of allyl glycidyl ether, 25 parts of methyl methacrylate, 15 parts of n-butyl methacrylate, 14 parts of dodecafluoroheptyl methacrylate, 25 parts of alumi...

Embodiment 3

[0059] A water-based organic-inorganic hybrid anti-corrosion coating, which consists of the following components in parts by weight: 90 parts of nano-material modified acrylate composite emulsion, 10 parts of ammonium fluorozirconate, 15 parts of sodium molybdate, titanate coupling agent 10 parts, methanol 5 parts, water 32 parts, defoamer (BYK022) 1 part, PH regulator 1.8 parts, leveling agent (BYK331) 0.3 parts, curing agent 5 parts.

[0060] The preparation of nanomaterial modified acrylate composite emulsion in the present embodiment is as follows:

[0061] 1) formula (parts by weight):

[0062] 1 part of N,N dimethylbisacrylamide, 1 part of polyethylene glycol dimethacrylate, 2 parts of acrylamide, 35 parts of styrene, 35 parts of butyl acrylate, 15 parts of hydroxyethyl methacrylate, 5 parts of acrylic acid, 1.5 parts of allyl glycidyl ether, 25 parts of methyl methacrylate, 15 parts of n-butyl methacrylate, 14 parts of dodecafluoroheptyl methacrylate, 15 parts of nano-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com