Engine composite carbon removing solution and device and working mode of engine composite carbon removing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

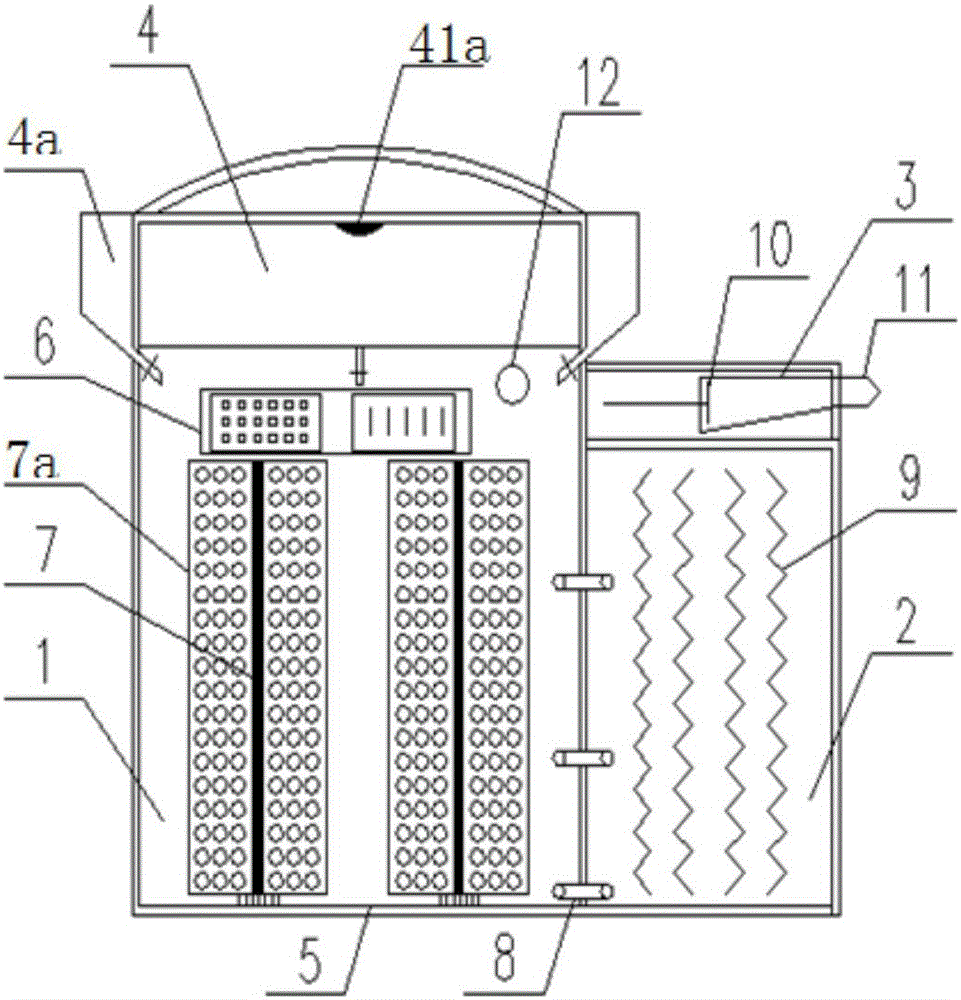

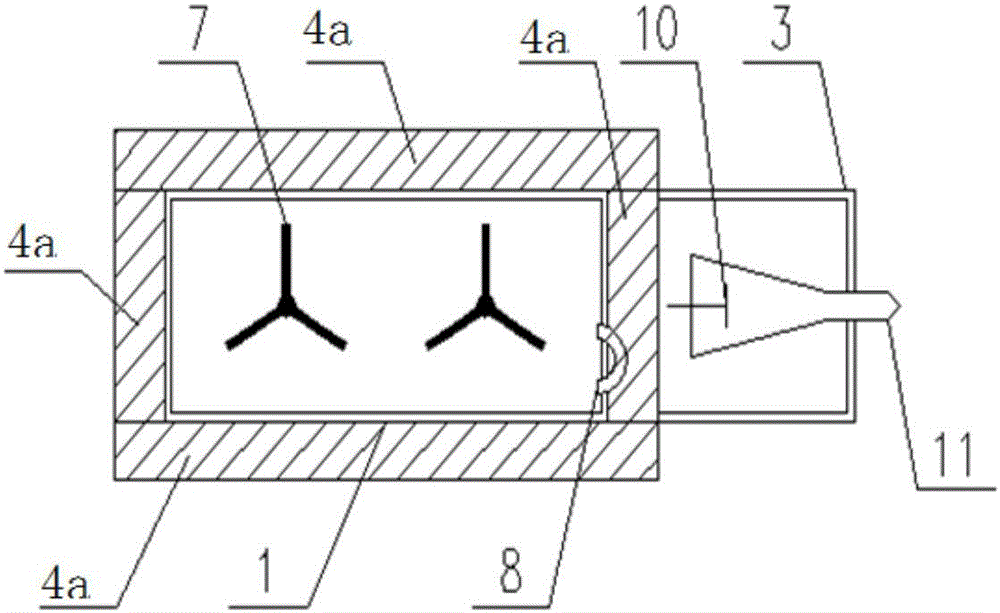

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0020] As shown in Figure 1, before the device starts to work, the solvent is sent into the composite decarbonization solution preparation unit 1 through the replenishment port 12, and the solvent quality added is weighed through the weighing unit 5, and the solvent quality is transmitted in the form of data to the central control system 6; the central control system 6 calculates the required mass of solute in each proportion, and feeds back the required solute mass to the solute storage unit 4, and the discharge valve of the solute storage sub-bin 4a in the solute storage unit 4 is opened, and the solute: 10% alkyl glucoside, 12% polyether amine, 15% purity of 95% ethanol, 6% sodium bicarbonate are added in the compound carbon removal solution preparation unit 1, and the residual capacity of each solute is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com