Two-in-one oil field heating furnace with high-pressure descaling system

A heating furnace, two-in-one technology, applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve the problems affecting the working efficiency of oil field heating furnaces, the need to stop the furnace for descaling work, and long processing time, etc., to achieve the installation effect Reliability, high degree of automation, convenient transformation and installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

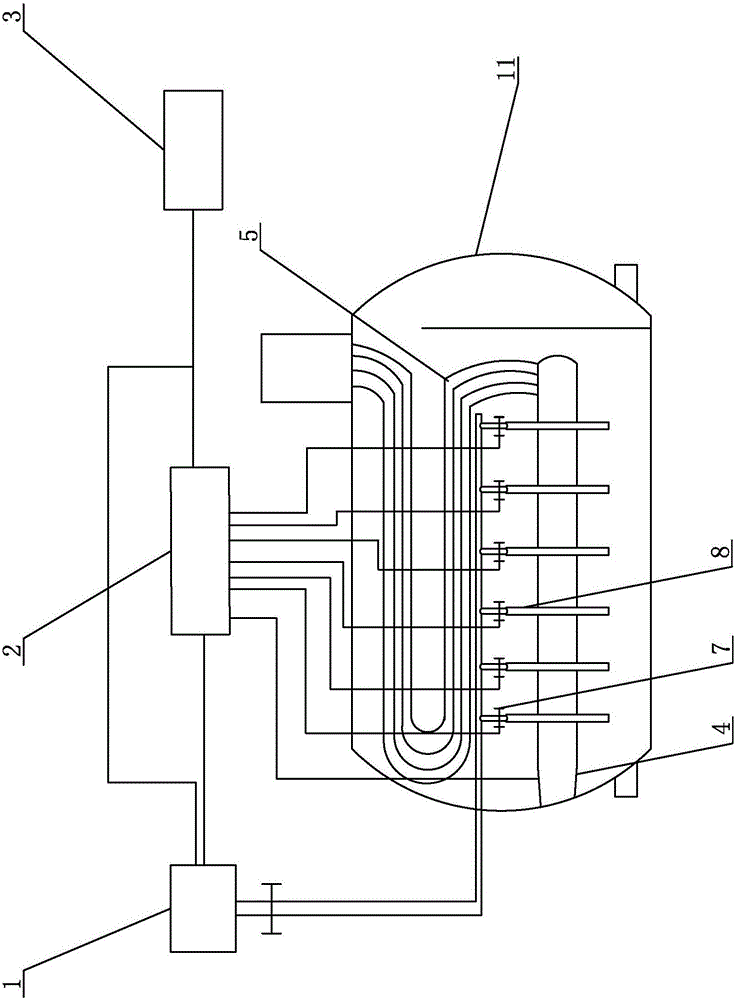

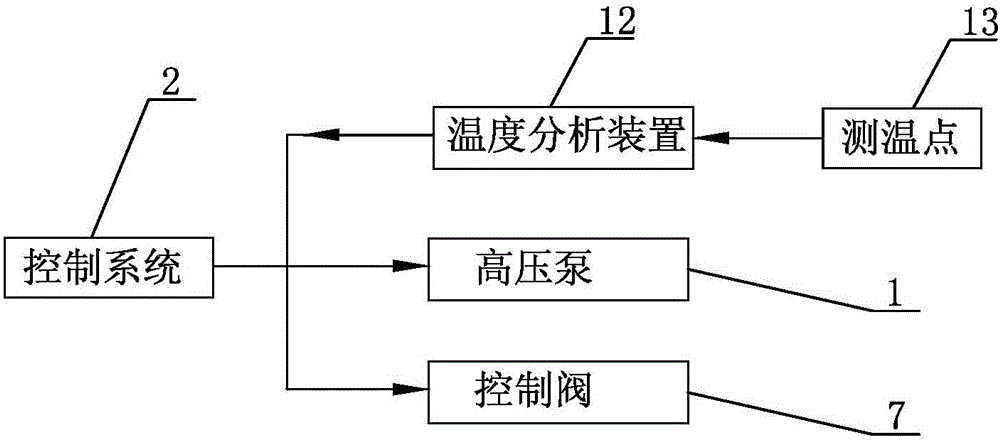

[0021] Specific implementation mode one: combine figure 1 , figure 2 with image 3 Describe this embodiment, this embodiment comprises high-pressure pump 1, control system 2, power supply 3, torch 4, heating furnace body 11 and a plurality of descaling devices, described heating furnace body 11 is provided with torch 4, and the plurality of The descaling devices are sequentially arranged on the torch 4 along the length direction of the torch 4, and the high-pressure pump 1 is arranged outside the heating furnace body 11 and communicates with each descaling device in the heating furnace body 11 through a pipeline assembly. The control system 2 is arranged outside the furnace body 11 and connected to each descaler in the furnace body 11 through a line assembly, and the power supply 3 is located outside the furnace body 11 and connected to the control system 2;

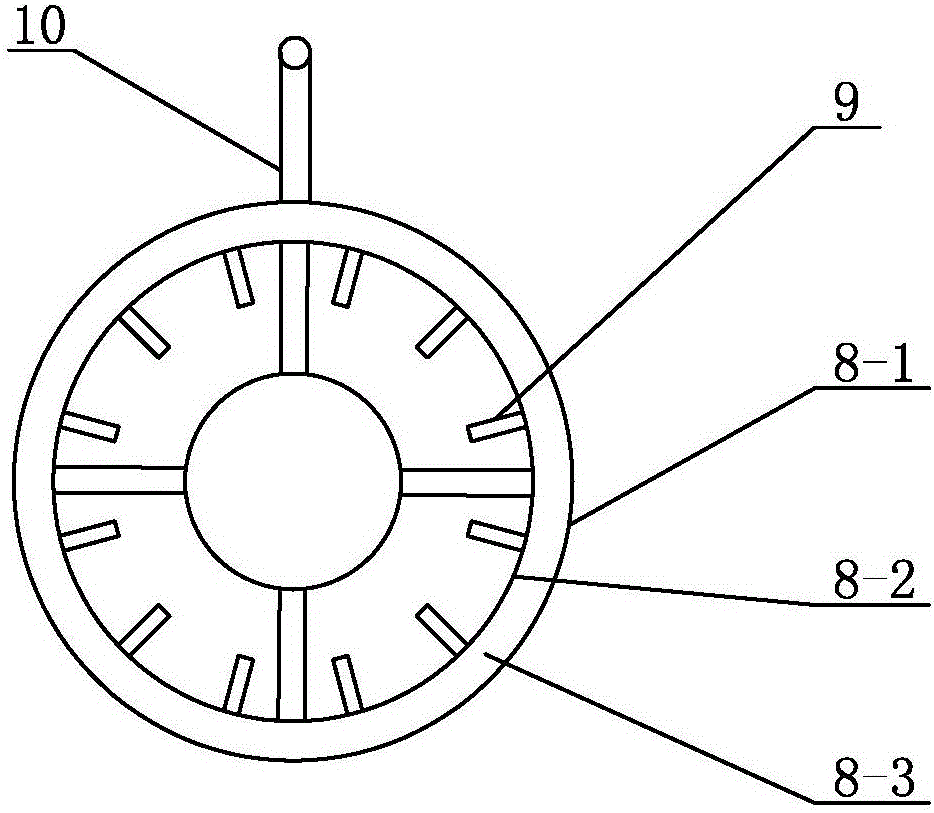

[0022] Each descaler comprises a control valve 7, a water spray ring 8 and a plurality of nozzles 9, the water spra...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 with figure 2 This embodiment is described. In this embodiment, each descaler corresponds to a bracket 10 , and the water spray ring 8 in each descaler is fixedly connected to the pipeline assembly through its corresponding bracket 10 .

[0029] In this embodiment, each descaling device corresponds to a bracket 10, that is, a plurality of brackets 10 are all arranged on a guide rail, and the guide rail is arranged in the heating furnace body 11, and each bracket 10 is slidably matched with the heating furnace body 11. Each descaler slides reciprocally along the length direction of the guide rail under the drive of its corresponding bracket 10, which enhances the flexibility of the present invention, that is, realizes the mobile spraying mode, and the injection power of each descaler comes from a plurality of nozzles 9. The reaction force of the jet stream. Other unmentioned structures and connections are the same...

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 with figure 2 Describe this embodiment, this embodiment also includes a plurality of smoke pipes 5, the plurality of smoke pipes 5 are arranged in parallel in the heating furnace body 11, one end of each smoke pipe 5 communicates with the fire tube 4, and each smoke pipe 5 The other end communicates with the smoke outlet outside the heating furnace body 11. Other unmentioned structures and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com