Sheet metal microcrack recognizing and positioning system and detection method based on system

A metal sheet and positioning system technology, which is applied to the analysis of solids, instruments, and materials using sonic/ultrasonic/infrasonic waves. It can solve the problem of low detection and recognition ability of small cracks, and achieve the effect of simplifying the extraction method and avoiding complex analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

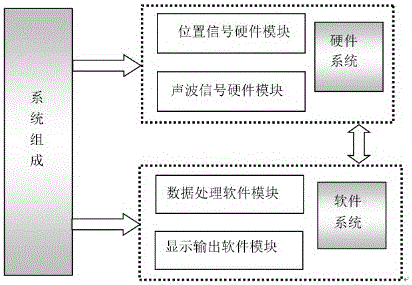

[0022] Specific implementation mode 1. Combination figure 1 This specific embodiment is described. The metal thin plate microcrack identification and location system and the detection method based on the system described in this specific embodiment include two parts: a hardware system and a software system.

specific Embodiment approach 2

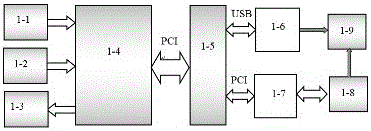

[0023] Specific embodiment two, combine figure 2 The difference between this embodiment and the metal sheet microcrack identification and positioning system described in Embodiment 1 and the detection method based on the system is that the hardware system includes a keyboard 1-1, a mouse 1-2, a printer 1- 3. Industrial computer 1-4, expansion station 1-5, position sensor probe 1-6, sound wave receiving / transmitting hardware module 1-7, piezoelectric transducer array 1-8, metal plate to be tested 1-9, It is composed of five data transmission lines, two sets of PCI peripheral parts interconnection standard data bus and USB universal serial bus. The industrial computer 1-4 is electrically connected to the expansion station through the PCI peripheral component interconnection standard data bus. The position sensor probes 1-6 are electrically connected to the expansion station through a USB universal serial bus. The sound wave receiving / transmitting hardware modules 1-7 are elec...

specific Embodiment approach 3

[0024] Specific embodiment three, combine figure 2 The difference between this specific embodiment and the metal thin plate microcrack identification and positioning system described in the second specific embodiment and the detection method based on this system is that the hardware system can be divided into position information collection and processing and acoustic wave information collection from the function. Dealing with hardware modules, but both structurally contain repetitive parts. The position information module mainly includes an industrial computer 1-4, an extension station, and a position sensor 1-6. The sound wave information collection and processing hardware module mainly includes industrial computer 1-4, expansion station, sound wave receiving / transmitting hardware module 1-7, and piezoelectric transducer array 1-8. The industrial control computer 1-4 controls the acoustic wave receiving / transmitting hardware module 1-7 and the position sensor probe 1-6 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com