Toner for developing electrostatic charge image

A manufacturing method and technology of toner, applied in the field of toner, can solve the problems of insufficient charging performance, stability and durability of toner, insufficient durability, and unsatisfactory image stability, etc., to achieve Effects of high durability, stable chargeability, and excellent image stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0230] Now, the present invention will be specifically described by way of examples, but the present invention will not be limited to these examples. "Parts" means "parts by mass".

[0231]

[0232] (step 1)

[0233] 2,5-Dihydroxybenzoic acid (100 g) and 80% sulfuric acid (1441 g) were heated to 50° C. and mixed. Tert-butanol (144 g) was added to the dispersion, and stirred at 50° C. for 30 minutes. Then, the operation of adding tert-butanol (144 g) to the dispersion liquid followed by stirring for 30 minutes was performed three times. The reaction solution was cooled to room temperature, and poured slowly into ice water (1 kg). The precipitate was filtered and washed with water and then with hexane. The precipitate was dissolved in methanol (200 mL), and reprecipitated in water (3.6 L). After filtration, the reaction product was dried at 80° C., thereby preparing a salicylic acid intermediate (74.9 g) represented by formula (4).

[0234] [Formula 4]

[023...

manufacture example

[0289] Methyl ethyl ketone (200.0 parts) was put into a reaction vessel equipped with a stirrer, a condenser, a thermometer and a nitrogen introduction tube, and resin A-1 (100.0 parts) was added and dissolved. A 1.0 mol / L potassium hydroxide aqueous solution was slowly added, and stirred for 10 minutes. Ion-exchanged water (500.0 parts) was slowly added dropwise to emulsify the solution. The emulsified product was distilled under reduced pressure to remove the solvent, and ion-exchanged water was added to adjust the concentration of the resin to 20%. An aqueous dispersion of resin particles E-1 was prepared. The physical property values of the aqueous dispersion of resin particles A are shown in Table 3.

[0290]

[0291] Resin pellets were prepared in the same manner as in the production example of resin pellets E-1, except that resin A-1 was changed to other polymers and the amount of 1.0 mol / L potassium hydroxide aqueous solution was changed as shown in Table 3...

Embodiment 1

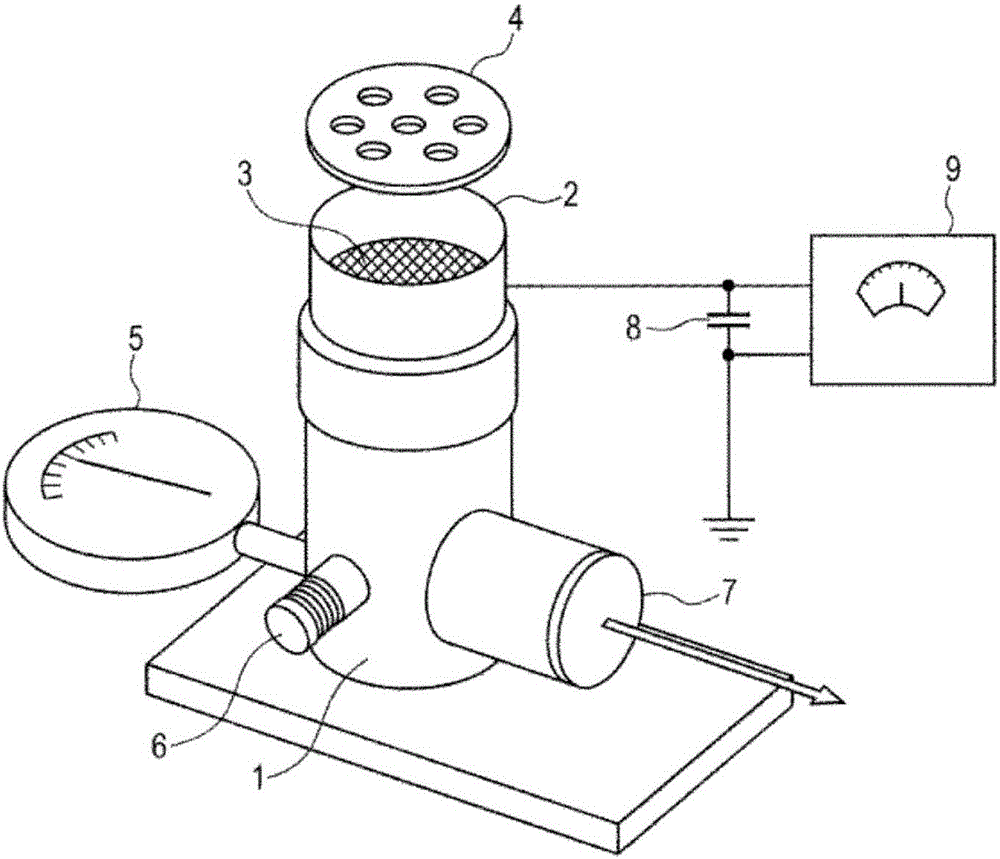

[0301] (Preparation of Toner Base Particles)

[0302] 0.1mol / L of Na 3 PO 4 The aqueous solution (850.0 parts) was put into a container equipped with a high-speed stirrer Clearmix (manufactured by MTechnique Co., Ltd.). The number of revolutions was adjusted to 15000 rpm, and the vessel was heated to 60°C. Add 1.0mol / L of CaCl to it 2 Aqueous solution (68.0 parts), thus prepares the dispersant Ca 3 (PO 4 ) 2 aqueous medium. After stirring for 30 minutes, the pH was adjusted to 6.0.

[0303] The materials listed below were dissolved at 100 r / min using a propeller stirrer to prepare a solution.

[0304] Styrene (70.0 parts)

[0305] n-butyl acrylate (30.0 parts)

[0306] Saturated polyester resin (3.0 parts)

[0307] (Bisphenol A copolymer modified by terephthalic acid-propylene oxide, acid value: 13mgKOH / g, Mw: 14500)

[0308] Next, add the materials listed below to the solution:

[0309] C.I. Pigment Blue 15:3 (6.5 parts)

[0310] Ester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com