Heavy oil slurry reactor hydrogenation reaction device and application method

A technology for hydrogenation reaction and hydrogenation reactor, which is applied in the fields of hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc. The effect of high conversion rate of heavy oil, increasing compatibility, and inhibiting possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

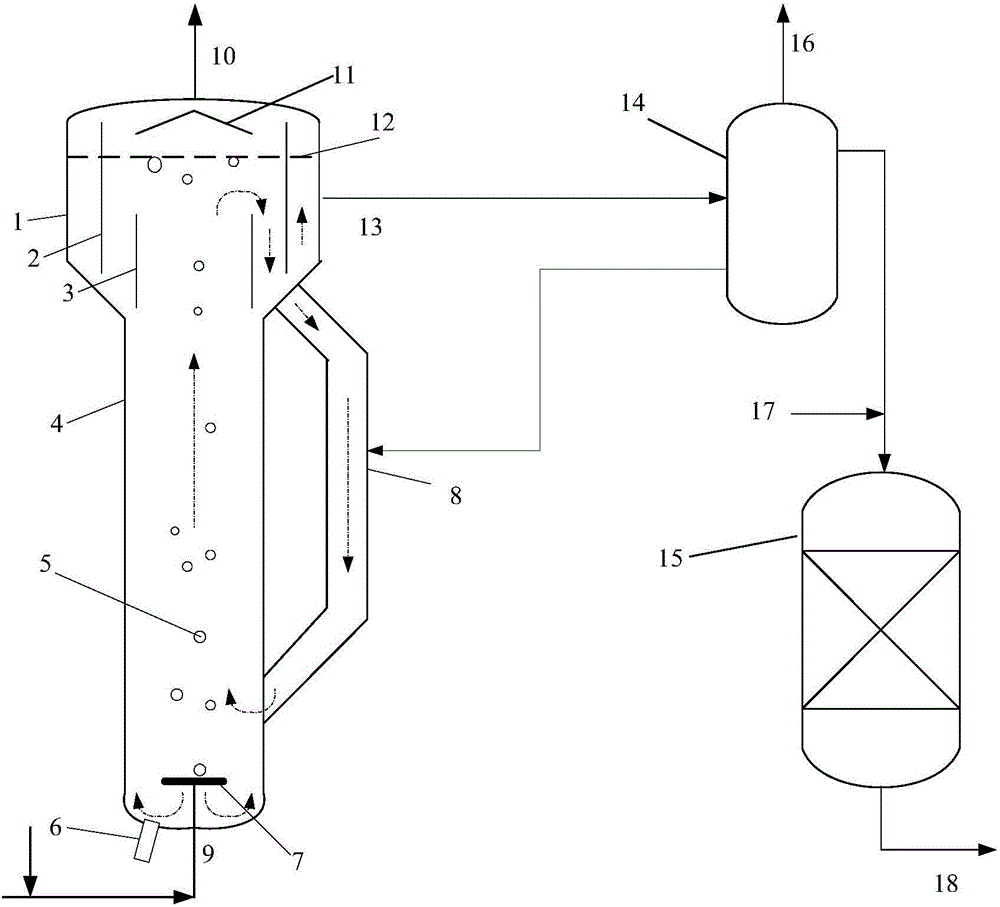

[0041] Use as attached figure 1 In the slurry bed reactor shown, the diameter ratio of the riser to the outer tube of the downcomer is 2:1, and the diameter ratio of the riser to the expansion section is 0.75:1. The diameter ratio of the inner cylinder to the outer cylinder of the slurry phase separator is 0.6:1. The connection position between the upper part of the downcomer and the expansion section is 1.5m away from the top of the riser, and the interface between the bottom of the downcomer and the riser is 2.5m away from the bottom of the riser.

[0042] Hydrocracking catalyst preparation method: metal precursor ammonium molybdate ((NH 4 )6Mo 7 o 24 4H 2 O), nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) and vanadium oxide (V 2 o 5 ) with a mass ratio of 3.3:4.16:1, added to water, and stirred evenly. Then add acid-treated activated carbon 3.5 times the total mass of the metal precursor and 0.34 times the vulcanizing agent (sublimed sulfur) into the autoclave, and vulcaniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com