Method for pure nature brewing of persimmon aromatic vinegar

A pure natural, persimmon technology, applied in the field of vinegar, to achieve the effect of good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Choose fresh persimmons that have matured after frost and place them in a place with a large temperature difference between day and night for about 40 days. Let the persimmons soften naturally until the astringency is removed and the taste is sweet and rich. Raise the temperature to above 2°C and place it for 12 hours. Repeat this twice to increase the sugar content of the persimmon fruit to above 20%, perform beating and separation, remove the persimmon pedicle, core, and skin dregs, put it into a fermentation container, and add pectinase 0.25%, 0.2% cellulase, 0.2% low-temperature Saccharomyces cerevisiae, stir evenly, control the temperature at about 15 degrees for low-temperature fermentation, the cycle is 15-20 days, the alcohol content is about 9%, add 0.1% acetic acid bacteria for acetic fermentation, The temperature is controlled at about 35°C, the fermentation process is continuously ventilated and stirred, and the time is 3-4 days. The acidity to be tested reac...

Embodiment 2

[0024] Choose fresh persimmons picked after frost, leave them to soften naturally for about 35 days, freeze them to increase the sugar content by 20%, and separate them by beating. After removing the persimmon pedicles and skin residues, put the persimmon juice into the tank, and add 0.26% pectinase , cellulase 0.21%, low-temperature wine yeast 0.21%, stir well, control the temperature 15-18 degrees; low-temperature fermentation for about 18 days, after testing, after the alcohol content is 8.8%, add 0.1% acetic acid bacteria, carry out acetic acid fermentation, temperature control 35 After 4 days at ℃, the acidity is 4.0%, and the alcohol content is reduced to 0.9%. After the fermentation is over, it is filtered and aged for 100 days, then filtered with diatomaceous earth, sterilized at 80 ℃ for 15-20 minutes, and the finished product is filled.

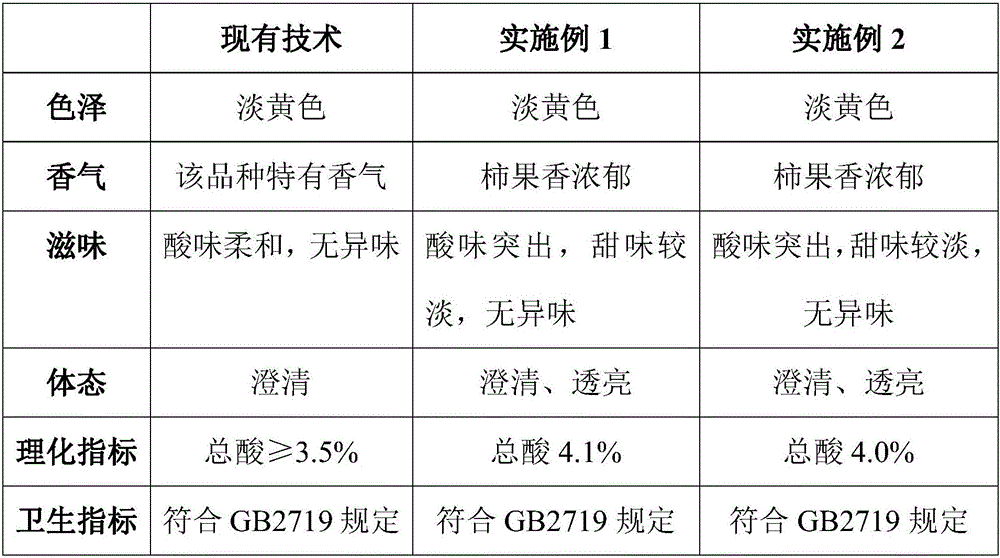

[0025] The present invention compares with the experimental effect of prior art as follows:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com