Salt-bath niobiumizing agent for surface of metallic titanium and niobiumizing method thereof

A metal titanium and salt bath technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of poor flexibility, high cost, poor industrial practicability, etc., and achieve the effect of good interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for infiltrating niobium in a salt bath on the surface of metal titanium, which comprises preparation of an infiltrating agent, pretreatment of the workpiece surface, pretreatment of the infiltrating agent, niobium infiltrating treatment and workpiece cleaning, wherein:

[0029] The preparation of osmotic agent refers to 840 grams of anhydrous borax (Na 2 B 4 o 7 ), 100 grams of niobium oxide (Nb 2 o 5 ) and 60 grams of silicon carbide (SiC) were mixed evenly and placed in an oven at 120°C for 40 minutes to obtain the required salt bath niobium infiltrating agent for the surface of titanium metal for use. The silicon carbide is commercially available green and pure silicon carbide with a particle size of 150-200 The purity of niobium oxide is at least 99.5%;

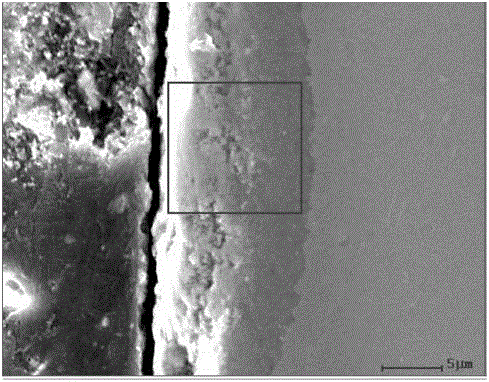

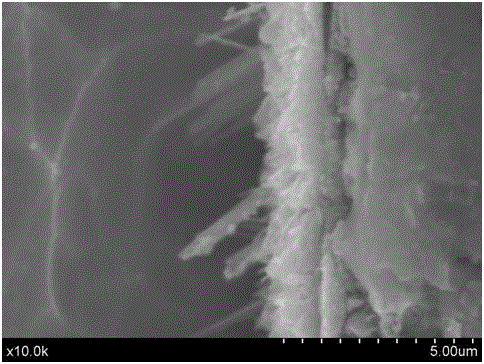

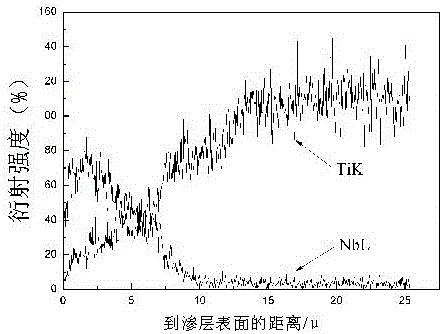

[0030] The surface pretreatment of the workpiece is to wire-cut the TC4 titanium alloy bar into 10mm×12mm×3mm profiles for later use. After degreasing and cleaning with deionized water, the surface o...

Embodiment 2

[0036] Method is basically identical with embodiment 1, and difference is that the niobium infiltrating agent formula that adopts is by 840 gram Na 2 B 4 o 7 (84%), 100 g Nb 2 o 5 (10%), 60 grams of SiC (6%).

[0037] Test after taking out the sample. The thickness of the infiltrated layer is 1.6 μm ( figure 2 ); the surface hardness of the infiltrated niobium layer is 1155HV, which is about 3.5 times the hardness of the matrix.

Embodiment 3

[0039] The method is basically the same as in Example 1, except that the temperature of niobium infiltration in the niobium infiltration method adopted is 1000°C.

[0040] After taking out the sample, it was tested that the surface hardness of the niobium infiltrated layer was 1071.8HV, about 3.2 times the hardness of the matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com