Environment-friendly chemical nickel stripper and deplating method thereof

A chemical nickel stripping agent, an environmentally friendly technology, applied in the field of environmentally friendly iron-based chemical nickel stripping agents, can solve problems such as increased factory costs, personal injury, and threats to the personal safety of staff, and achieves simple and convenient maintenance operations and shortened production cycles. , The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

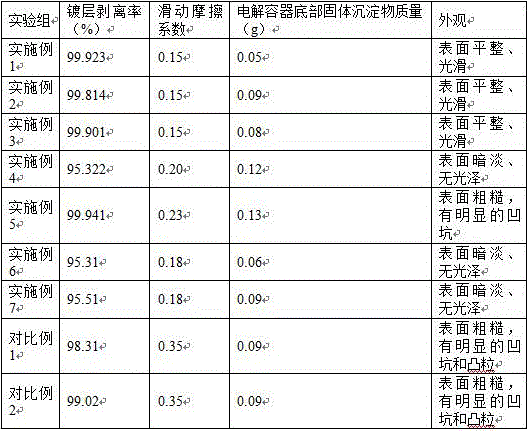

Examples

Embodiment 1

[0036] Present embodiment provides a kind of environment-friendly chemical stripping nickel agent, and its raw material comprises by weight:

[0037] 50 parts of oxidizing agent;

[0038] 30 parts of buffer;

[0039] 40 parts of corrosion inhibitor;

[0040] 65 parts of complexing agent;

[0041] 4 parts conductive salt;

[0042] Wherein, the oxidizing agent is sodium m-nitrobenzoate, the buffering agent is sodium diethyldithiocarbamate, the corrosion inhibitor is ethylenediamine, the complexing agent is ammonium citrate, and the conductive salt Sodium dodecyl sulfonate. In this embodiment, the coating is a nickel coating.

Embodiment 2

[0044] Present embodiment provides a kind of environment-friendly chemical stripping nickel agent, and its raw material comprises by weight:

[0045] 30 parts of oxidizing agent;

[0046] 30 parts of buffer;

[0047] 40 parts of corrosion inhibitor;

[0048] 65 parts of complexing agent;

[0049] 4 parts conductive salt;

[0050] Wherein, the oxidizing agent is sodium m-nitrobenzoate, the buffering agent is sodium diethyldithiocarbamate, the corrosion inhibitor is ethylenediamine, the complexing agent is ammonium citrate, and the conductive salt Sodium dodecyl sulfonate. In this embodiment, the coating is a nickel coating.

Embodiment 3

[0052] Present embodiment provides a kind of environment-friendly chemical stripping nickel agent, and its raw material comprises by weight:

[0053] 60 parts of oxidizing agent;

[0054] 30 parts of buffer;

[0055] 40 parts of corrosion inhibitor;

[0056] 65 parts of complexing agent;

[0057] 4 parts conductive salt;

[0058] Wherein, the oxidizing agent is sodium m-nitrobenzoate, the buffering agent is sodium diethyldithiocarbamate, the corrosion inhibitor is ethylenediamine, the complexing agent is ammonium citrate, and the conductive salt Sodium dodecyl sulfonate. In this embodiment, the coating is a nickel coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com