A manufacturing method of an amorphous alloy iron core with an ultra-thin epoxy resin coating

A technology of epoxy resin coating and amorphous alloy, which is applied in the manufacture of inductors/transformers/magnets, electrical components, transformer/inductor cores, etc. Solve the problems of magnetic properties, core unit loss and large excitation power, etc., to achieve the effect of excellent soft magnetic properties, good versatility, low unit loss and excitation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

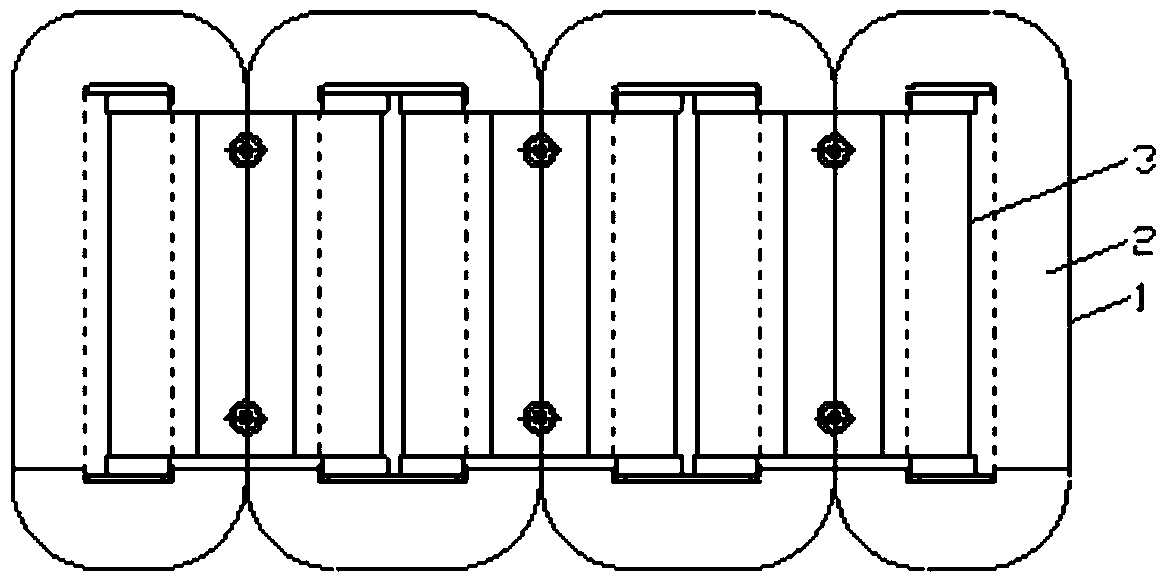

[0028] A method for manufacturing an amorphous alloy iron core with an ultra-thin epoxy resin coating, comprising the following steps:

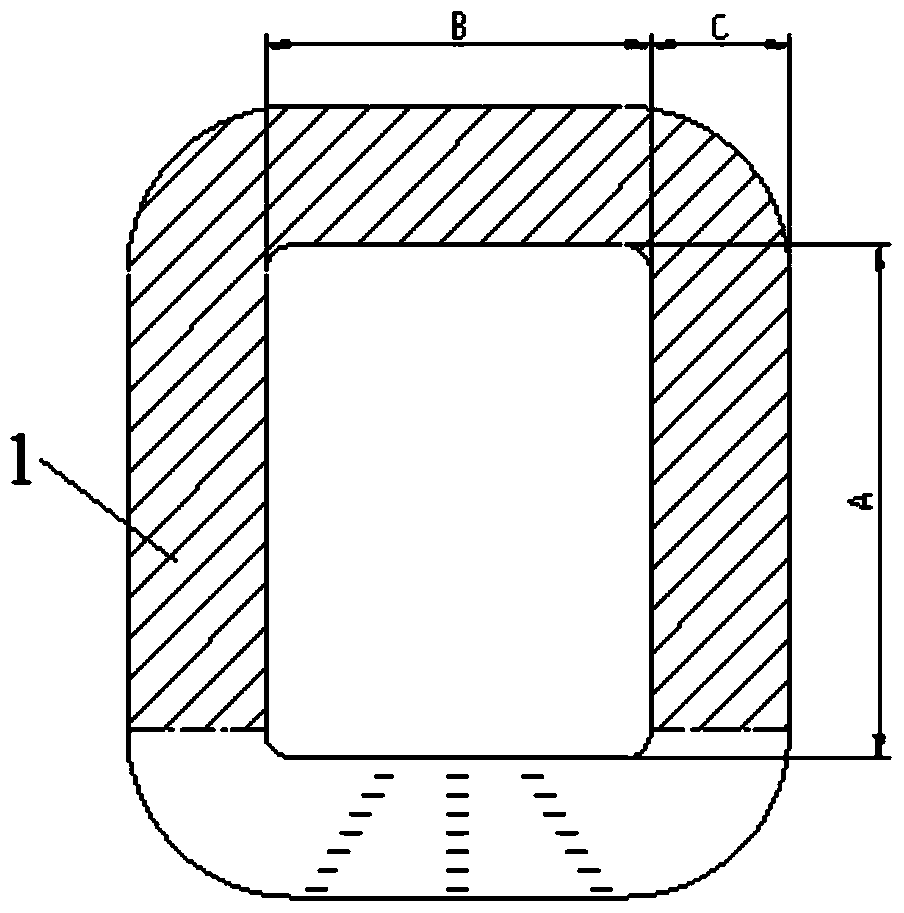

[0029] (1) Superimpose the iron core with multiple pieces of amorphous alloy strips with a width of 142 mm, remove debris and impurities on the end face of the iron core, and separate the epoxy coated surface with shielding tape to ensure that the epoxy is only in the required area during epoxy coating. within the coated area;

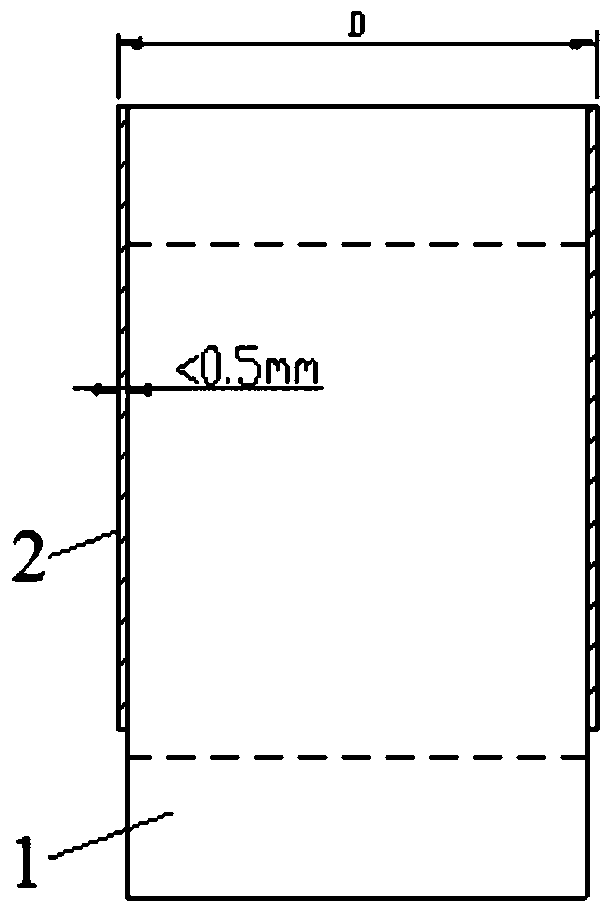

[0030] (2) After the epoxy resin and curing agent are evenly prepared in a weight ratio of 4:1, slowly apply the fully mixed epoxy resin to one end of the iron core with a spatula. After the epoxy resin is fully penetrated, apply the epoxy resin The thickness of the coating is controlled within 0.5mm to ensure the smooth surface of the epoxy resin coating;

[0031] (3) Carry out heating and curing treatment to the coated epoxy resin, the temperature is controlled at 130-150° C., and the curing time is 50-70 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com