Method and system for achieving enhanced HEMT device through electrochemical corrosion

An enhanced, electrochemical technology, applied in electrical components, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve problems such as affecting device stability, difficult recessed gate structure process, and degrading device performance, to improve repeatability, Easy to mass-produce, less etching damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

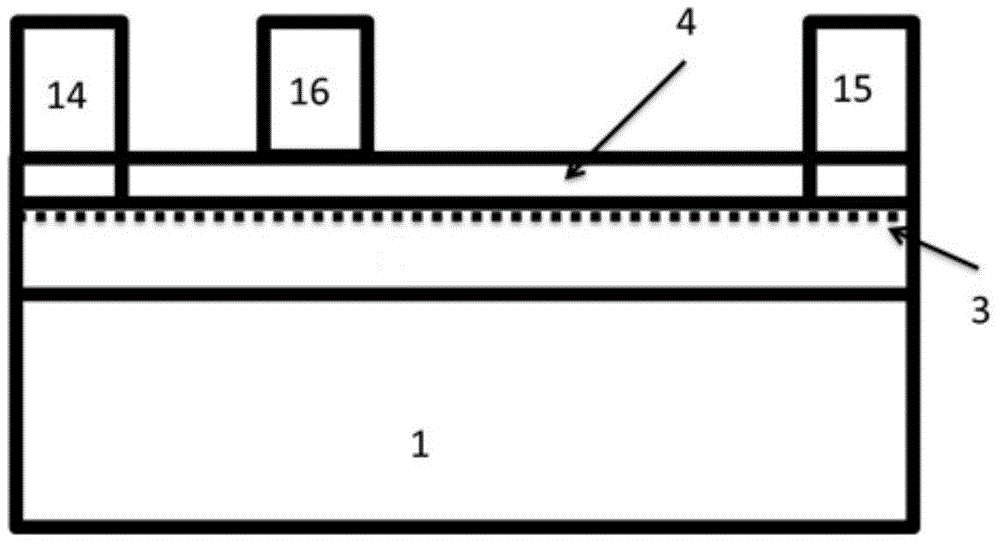

[0038] Such as figure 1 As shown, for common HEMT devices (taking AlGaN / GaN devices as an example), generally speaking, when zero bias voltage or no bias voltage is applied to the gate electrode 16, both the source electrode 14 and the drain electrode 15 are connected to the two-dimensional electron gas 3-phase connection, so the source electrode 14 and the drain electrode 15 of the HEMT device are turned on, and the HEMT device is in the open state. Generally, this kind of HEMT device is called a depletion HEMT device, and it can also be called a normally-on HEMT device. In order to make the HEMT device in the off state, the two-dimensional electron gas 3 between the source electrode 14 and the drain electrode 15 must be depleted or the two-dimensional electron gas in a certain regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com