Fin-type field-effect transistor with Omega-shaped top gate structure and preparation method of fin-type field-effect transistor

A fin field effect and transistor technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of lack of top gate channel cross-sectional area, small equivalent Fin thickness, large leakage current, etc. The effect of low cost, high on-state current, and small source-drain series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

[0083] The preparation of N-type Ω-type top-gate structure fin field-effect transistors on SOI substrates can be realized according to the following steps:

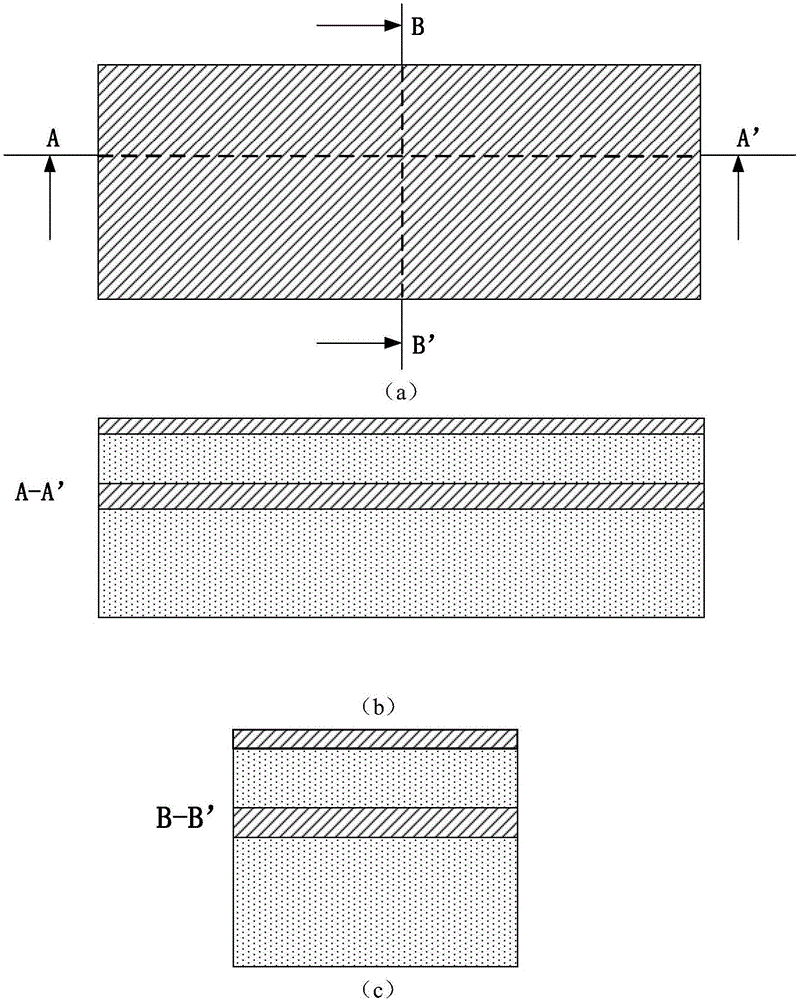

[0084] 1) On the P-type (100) SOI substrate, the top silicon film will be thinned to 250nm by HNA solution, LPCVDSiO 2 100nm as mask layer 1, such as figure 1 shown;

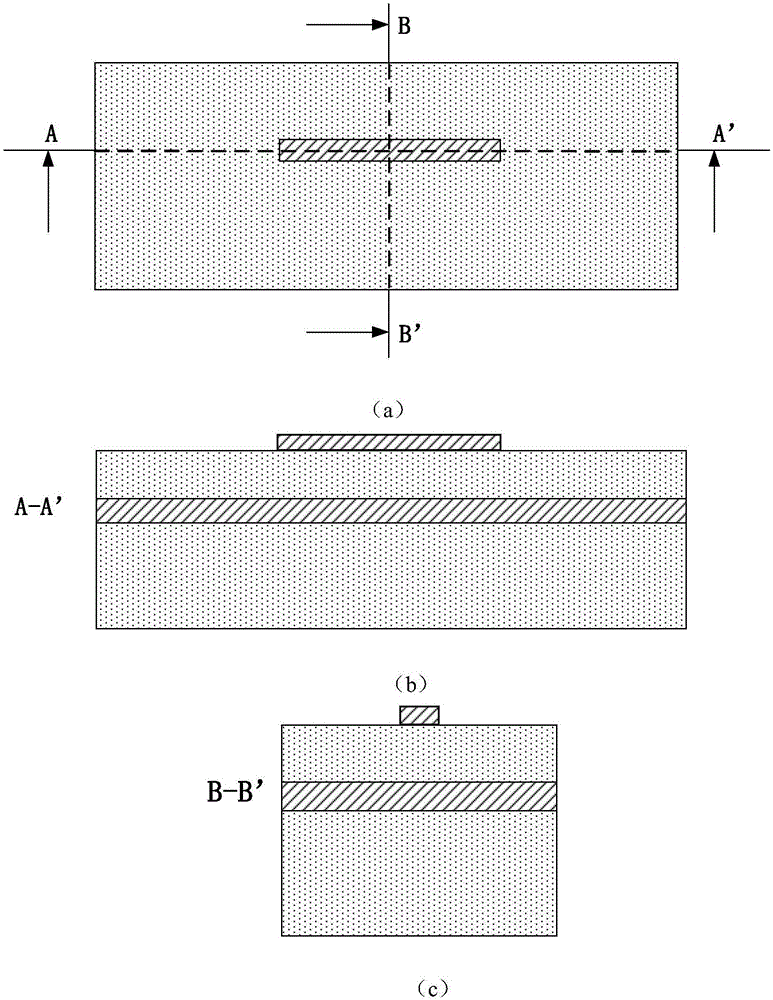

[0085] 2) Define the mask pattern of the channel region with a length of 100nm and a width of 50nm by electron beam lithography, that is, the line width of the top of the Ω-type Fin is 50nm, using photoresist as a mask, and ICP etching mask layer 1 to form a rectangular Fin mask film, the line width of the rectangular Fin mask is 50nm, which is the line width at the top of the Ω-type Fin, and the adhesive is removed, such as figure 2 shown;

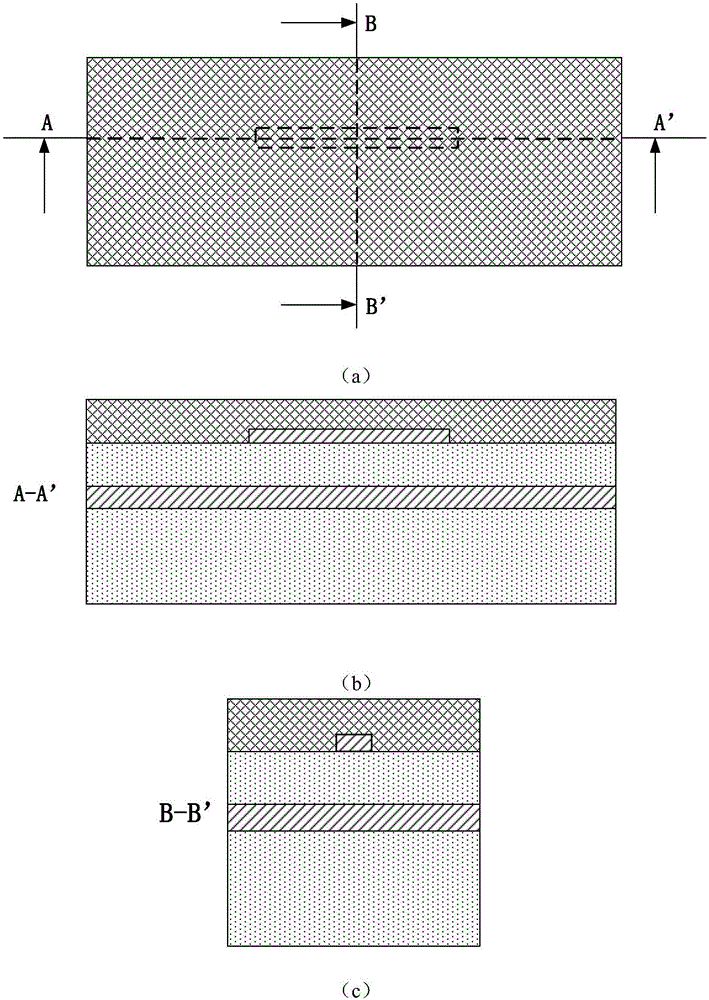

[0086] 3) LPCVD 300nm silicon nitride is used as the mask layer 2, the mask la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com