Ni-based anode material resistant to carbon deposition, preparation method and use

An anode material, anti-carbon technology, applied in the direction of fuel cells, battery electrodes, structural parts, etc., can solve the problem that the catalytic activity cannot be compared with Ni-based anodes, so as to improve the anti-carbon performance and long-term stability, reduce Small exposed area, inhibits the effect of growing over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] This example is used to illustrate the 1mol% MgO doped NiO-30wt%Sm 0.2 Ce 0.8 o 1.9 Anode materials and methods for their preparation.

[0089] First, 1 mol% MgO-doped NiO powder was prepared by a glycine combustion method, which included the following steps:

[0090] (1) take nickel nitrate and magnesium nitrate by stoichiometric ratio, and join in deionized water, form aqueous solution;

[0091] (2) in the aqueous solution that step (1) makes, add glycine as complexing agent, after glycine dissolves, continue to stir for about 2 hours to fully complex, wherein, the molar number of added glycine is 1 / 2 (NO 3- moles of -NH 4+ moles).

[0092] (3) The aqueous solution containing about 0.02mol of nickel nitrate obtained in step (2) is taken at a time, placed in a 1000-ml beaker, heated on a 500-watt electric heating plate, and slowly evaporated at 80°C After the solution becomes viscous (that is, a jelly is formed), continue heating at 300°C, the jelly burns and spr...

Embodiment 2

[0096] This example is used to illustrate the 2mol% MgO coated NiO-20wt% Sm 0.2 Ce 0.8 o 1.9 Anode materials and methods for their preparation.

[0097] First, adopt the sol-gel (sol-gel) method to coat nano-scale MgO on the particle surface of NiO powder, this method specifically comprises the following steps:

[0098](1) Calcining 3 grams of NiO powder prepared by glycine combustion method at 850° C. for 2 hours, then adding 8 milliliters of 0.1 mol / L magnesium methoxide in ethanol, and stirring for 5 hours;

[0099] (2) The product obtained in step (1) was dried at 120° C. and calcined at 500° C. for 1 h to obtain a NiO sample coated with 2 mol% MgO.

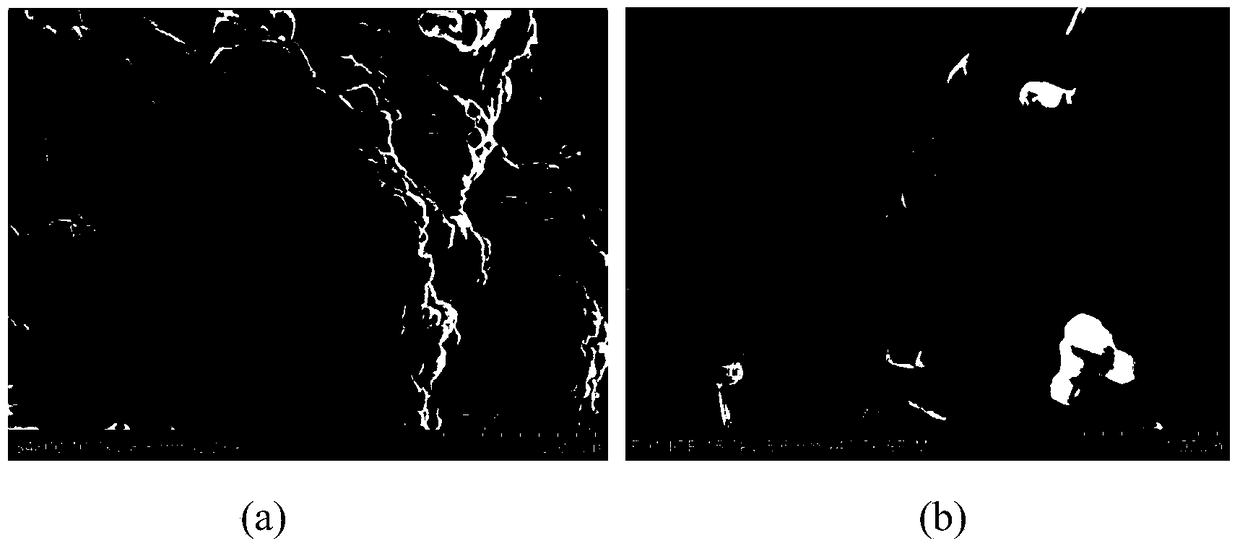

[0100] Using a scanning electron microscope to observe the size and morphology of the 2mol% MgO-doped NiO powder sample particles, the results are as follows image 3 shown.

[0101] Then, the prepared 2mol% MgO-coated NiO powder sample and Sm 0.2 Ce 0.8 o 1.9 The powder is mechanically ground and mixed uniformly at a...

Embodiment 3

[0103] This example is used to illustrate doping with 1mol% MoO 3 Doped NiO-20wt%Sm 0.2 Ce 0.8 o 1.9 Anode materials and methods for their preparation.

[0104] First, 1 mol% MoO was prepared by the glycine combustion method 3 The NiO powder of doping, the NiO powder that this method prepares 1mol% MgO doping in the embodiment 1 is basically the same, difference is: what used in step (1) is the nickel nitrate and molybdic acid that take by stoichiometric ratio Ammonium ((NH) 4 Mo 7 o 24 .4H 2 O).

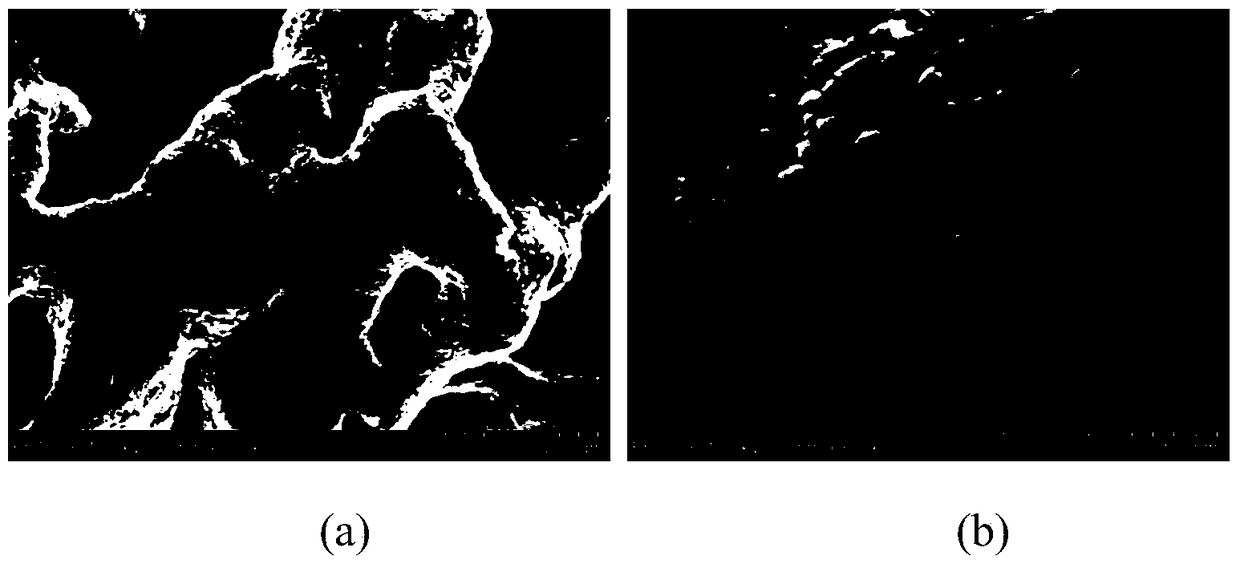

[0105] Observation of 1 mol% MoO by scanning electron microscopy 3 The size and morphology of the doped NiO powder sample particles, the results are as follows Figure 4 shown.

[0106] Then the 1mol% MoO synthesized by glycine combustion method 3 Doped NiO powder and Sm 0.2 Ce 0.8 o 1.9 The powder is mechanically ground and mixed uniformly according to the mass ratio of 80:20, and the target product is obtained, and the number is No.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com