A preparation method of vanadium dioxide film with heat-reflectivity response

A vanadium dioxide and reflectivity technology, applied in the field of vanadium dioxide thin film and its preparation, can solve the problems of inability to adjust negative temperature feedback and high phase transition temperature, and achieve stable time-consuming, strong chemical stability, and good thermo-optical response. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

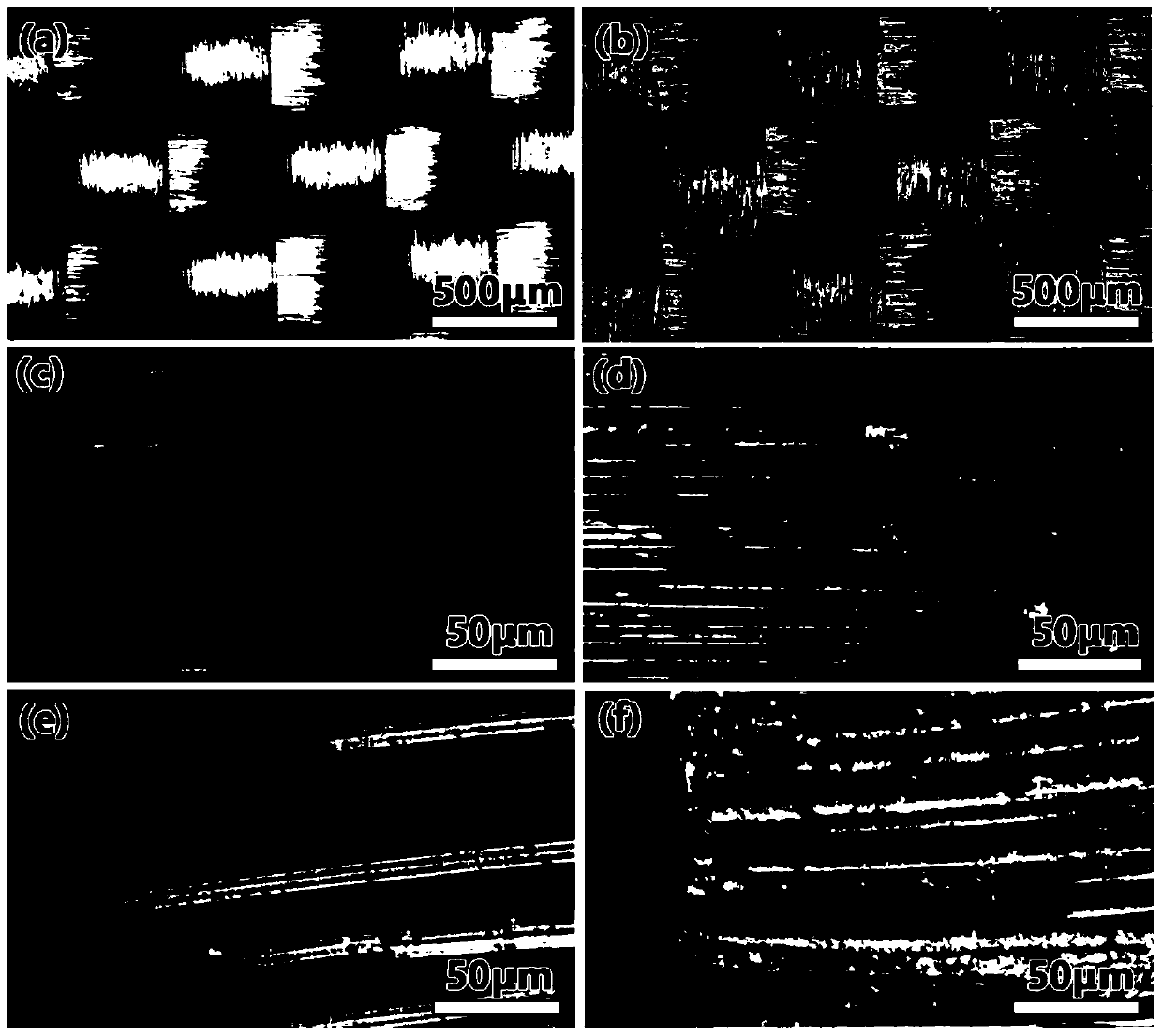

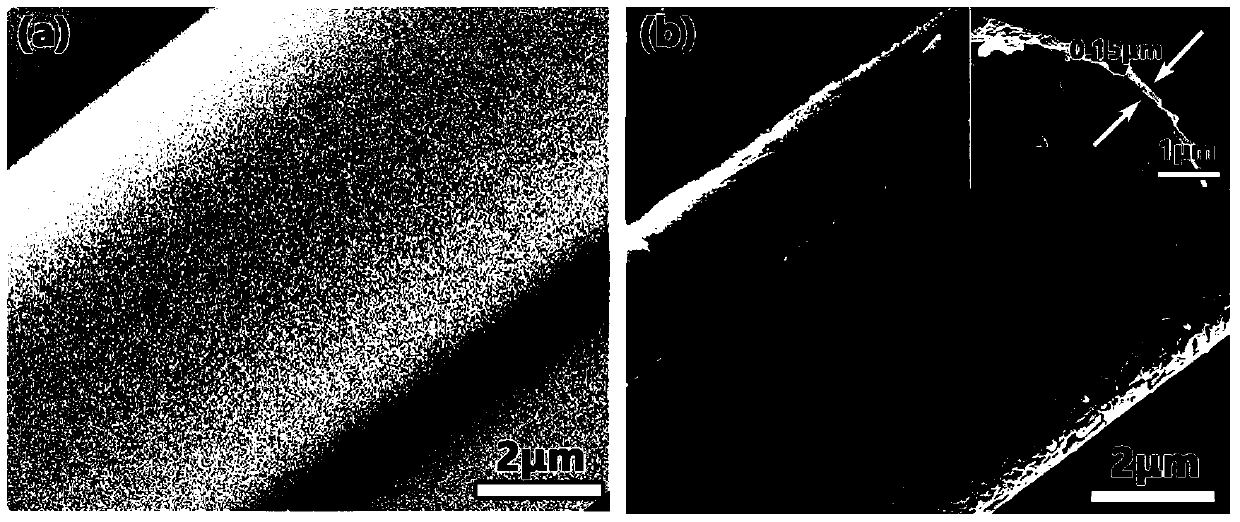

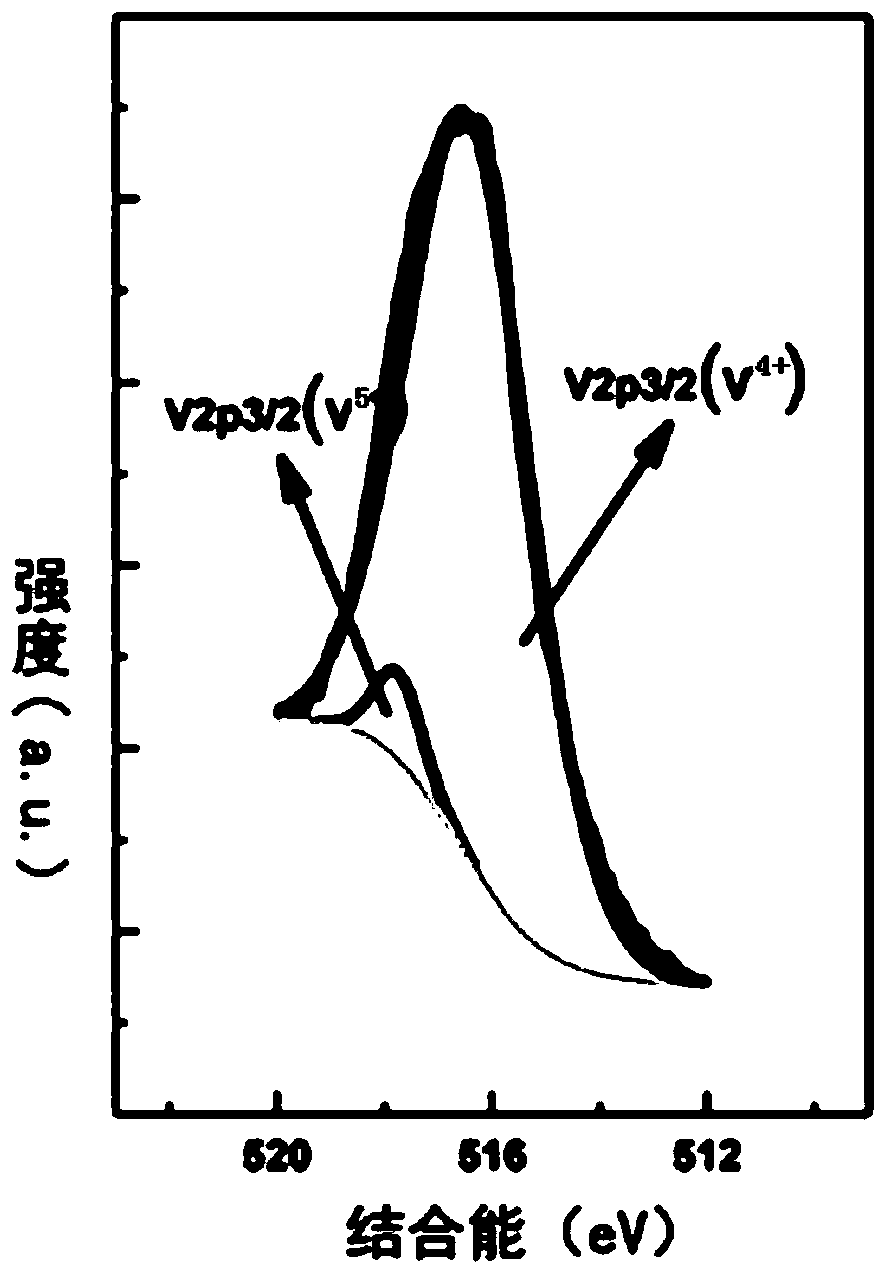

Embodiment 1

[0042] Choose 100m 2 / g Alkali-free E-type glass fiber cloth as the carrier, first place the carrier in a muffle furnace for heat treatment at 500°C for 2 hours to remove the sizing agent on the surface of the glass fiber, and then ultrasonicate the treated glass fiber cloth for 1 hour to further remove Sizing remaining on glass fiber surface. Will 5g V 2 o 5 The powder was placed in a muffle furnace and heated at 800 °C for 30 min to obtain molten V 2 o 5 , quickly poured into 300ml cold distilled water for quenching, stirred for 10min, and filtered to remove the residue to obtain a brown sol solution. The main component of the sol solution solute is H x V 2 o 5. Soak the pre-treated glass fiber cloth in the prepared sol solution for 10 seconds, then place the glass fiber in an oven for drying. The temperature of the oven is set at 60°C. Repeat the above operation 10 times to obtain a dark brown glass fiber cloth. Clamp the dark brown fiberglass cloth quartz piece int...

Embodiment 2

[0044] Choose 120m 2 / g Alkali-free E-type glass fiber cloth is used as the carrier. First, the carrier is placed in a muffle furnace for heat treatment at 450°C for 3 hours to remove the sizing agent on the surface of the glass fiber, and then the treated glass fiber cloth is ultrasonicated for 2 hours to further remove Sizing remaining on glass fiber surface. Will 5g V 2 o 5 The powder was placed in a muffle furnace and heated at 750 °C for 40 min to obtain molten V 2 o 5 , quickly poured into 100ml cold distilled water to quench, stirred for 10min, and filtered to remove the residue to obtain a brown sol solution. The main component of the sol solution solute is H x V 2 o 5 . Soak the pretreated glass fiber cloth in the prepared sol solution for 8 seconds, then place the glass fiber in an oven for drying, the oven temperature is set at 55°C, and repeat the above operation 8 times to obtain a dark brown glass fiber cloth. Clamp the dark brown fiberglass cloth quartz ...

Embodiment 3

[0046] Choose 80m 2 / g non-alkali E-type glass fiber cloth as the carrier, first place the carrier in a muffle furnace for heat treatment at 550°C for 1 h to remove the sizing agent on the surface of the glass fiber, and then ultrasonicate the treated glass fiber cloth for 1.5 h, further Remove the sizing remaining on the surface of the fiberglass. Will 5g V 2 o 5 The powder was placed in a muffle furnace and heated at 850 °C for 20 min to obtain molten V 2 o 5 , quickly poured into 500ml cold distilled water for quenching, stirred for 10min, and filtered to remove the residue to obtain a brown sol solution. The main component of the sol solution solute is H x V 2 o 5 . Soak the pretreated glass fiber cloth in the prepared sol solution for 12 seconds, then arrange the glass fiber in an oven for drying, the oven temperature is set at 65°C, and repeat the above operation 12 times to obtain a dark brown glass fiber cloth. Clamp the dark brown fiberglass cloth quartz piece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com