Preparation method of sorbitan oleate

A technology of sorbitan oleate and oleic acid, which is applied in the field of preparation of sorbitan oleate, achieves the effects of high stability, improved performance and reduced color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

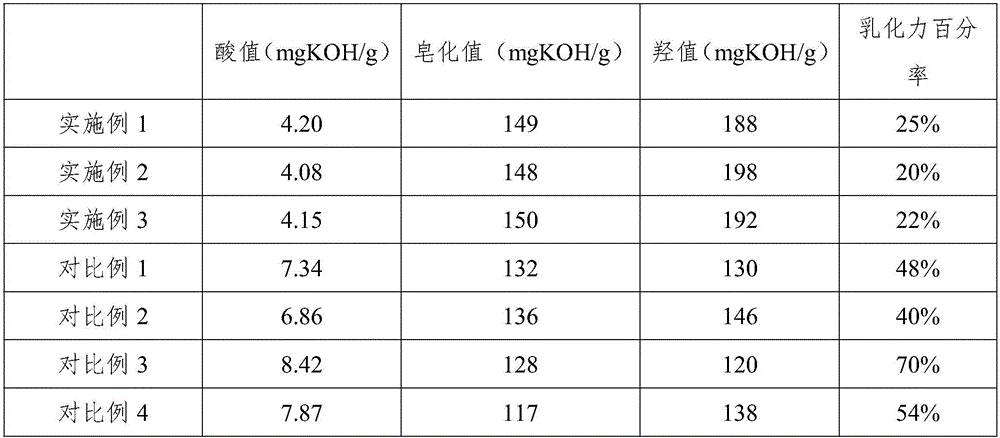

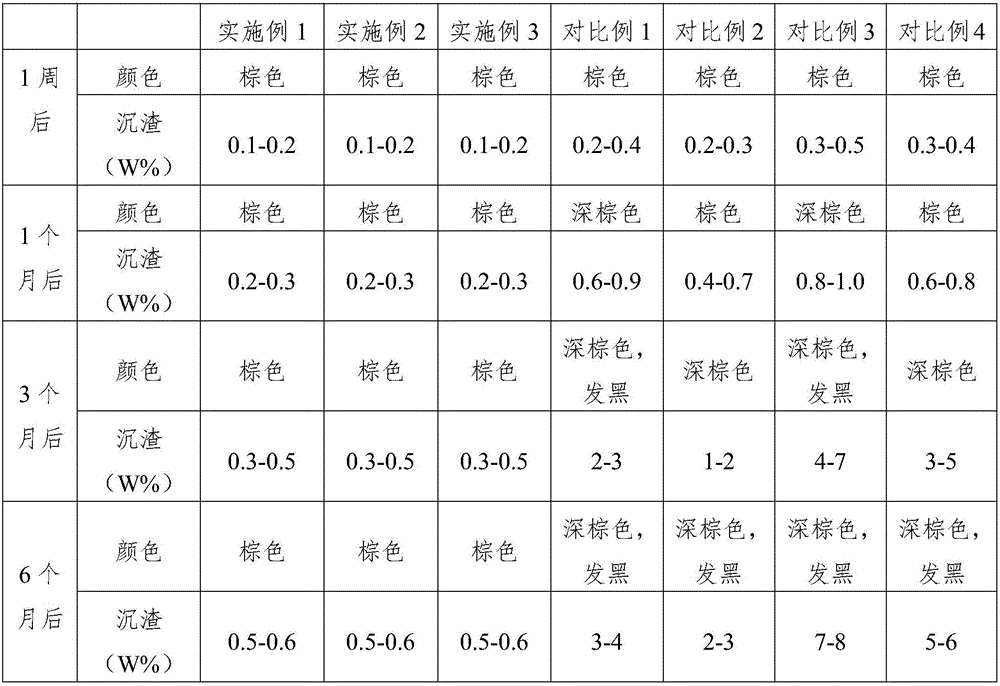

Examples

Embodiment 1

[0027] Embodiment 1, a kind of preparation of sorbitan oleate

[0028] S1 gets the solid sorbitol powder and places it in the reactor, raises the temperature to 90° C., stirs to a molten state, adds catalyst I, and the addition amount of the catalyst I is 4% of the solid sorbitol powder weight, and the catalyst I consists of four Butylammonium bromide and p-toluenesulfonic acid are composed of 3:2 by weight, stirred evenly, dehydrated at a temperature of 100°C and a vacuum of 0.006MPa for 2 hours, filtered, and added activated carbon when the temperature was lowered to 35°C. 50min, the addition of the activated carbon is 0.3% of the total weight of solid sorbitol powder and catalyst I, the average particle diameter of the activated carbon is 48 μm, filtered, concentrated, and dried to obtain 1,4-sorbitol;

[0029] S2 adds oleic acid and catalyst II to the 1,4-sorbitan that step S1 obtains, and the weight ratio of described 1,4-sorbitan and oleic acid is 1:1.72, the addition am...

Embodiment 2

[0030] Embodiment 2, a kind of preparation of sorbitan oleate

[0031] S1 gets the solid sorbitol powder and places it in the reactor, raises the temperature to 95° C., stirs to a molten state, adds catalyst I, and the addition amount of the catalyst I is 3% of the solid sorbitol powder weight, and the catalyst I consists of four Butylammonium bromide and p-toluenesulfonic acid are composed of 4:1 by weight, stirred evenly, dehydrated at a temperature of 105°C and a vacuum of 0.008MPa for 1 hour, filtered, and added activated carbon when the temperature was lowered to 40°C. 40min, the addition of the activated carbon is 0.4% of the total weight of solid sorbitol powder and catalyst I, the average particle diameter of the activated carbon is 50 μm, filtered, concentrated, and dried to obtain 1,4-sorbitol;

[0032]S2 adds oleic acid and catalyst II to the 1,4-sorbitan that step S1 obtains, and the weight ratio of described 1,4-sorbitan and oleic acid is 1:1.82, the addition amou...

Embodiment 3

[0033] Embodiment 3, a kind of preparation of sorbitan oleate

[0034] S1 gets the solid sorbitol powder and places it in the reactor, raises the temperature to 100° C., stirs to a molten state, adds catalyst I, and the addition amount of the catalyst I is 2% of the solid sorbitol powder weight, and the catalyst I consists of four Butylammonium bromide and p-toluenesulfonic acid are composed of 5:0.5 by weight, stirred evenly, dehydrated at a temperature of 115°C and a vacuum of 0.01MPa for 1 hour, filtered, and added activated carbon when the temperature was lowered to 45°C. 30min, the addition amount of described gac is 0.5% of the total weight of solid sorbitol powder and catalyst 1, the average particle diameter of described gac is 55 μ m, filter, concentrate, dry, obtain 1,4-sorbitol;

[0035] S2 adds oleic acid and catalyst II to the 1,4-sorbitan that step S1 obtains, and the weight ratio of described 1,4-sorbitan and oleic acid is 1:1.95, the addition amount of describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com