Method for preparing biodiesel by utilizing waste animal and vegetable oil

A technology for discarding animals, plants, and biodiesel, which is applied in the field of biodiesel preparation, and can solve the problems of no disclosed embodiment, unfavorable industrialized production of biodiesel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

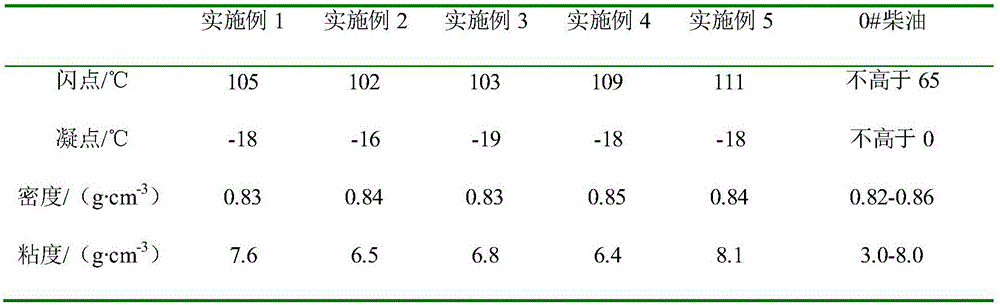

Examples

Embodiment 1

[0023] Heat 10L of waste animal and vegetable fats and oils to liquefy them, and filter to remove impurities once; put the filtered liquid waste fats and oils in a heating container, heat up and start stirring at a speed of 800 rpm, and then add 1.8L of pure Water, 1.5% sulfuric acid, when the temperature rises to 80°C, react at 80-85°C for 1-1.5h, then put the hydrolyzed waste grease into layers and separate to obtain the upper organic solution; put the obtained organic solution in In the heating container, raise the temperature and start stirring at 1000 rpm, and add 1L of methanol. When the temperature rises to 65°C, keep the temperature constant and react for 0.5-1h; Most of the glycerin and the remaining light liquid part were distilled at 60-65°C to obtain 9.6L of biodiesel after removing water.

Embodiment 2

[0025] Heat 10L of waste animal and vegetable fats and oils to liquefy them, and filter to remove impurities 3 times; put the filtered liquid waste fats and oils in a heating container, heat up and start stirring at a speed of 1000 rpm, and then add 2.0L of pure Water, 1.6% sulfuric acid, when the temperature rises to 80°C, react at 80-85°C for 1-1.5h, then put the hydrolyzed waste grease into layers, and separate to obtain the upper organic solution; place the obtained organic solution in In the heating vessel, raise the temperature and start stirring at 1100 rpm, and add 1.8L of methanol. When the temperature rises to 65°C, keep the temperature constant and react for 0.5-1h; The larger part of glycerin and the remaining light liquid part were distilled at 60-65°C to obtain 9.9L of biodiesel after removing water.

Embodiment 3

[0027] Heat 10L of waste animal and vegetable fats and oils to liquefy them, and filter to remove impurities once; put the filtered liquid waste fats and oils in a heating container, heat up and start stirring at a speed of 1000 rpm, and then add 1.8L of pure Water, 2.0% sulfuric acid, when the temperature rises to 80°C, react at 80-85°C for 1-1.5h, then put the hydrolyzed waste grease into layers, and separate to obtain the upper organic solution; put the obtained organic solution in In the heating container, raise the temperature and start stirring at 1000 rpm, and add 1.2L of methanol. When the temperature rises to 65°C, keep the temperature constant and react for 0.5-1h; The larger part of glycerin and the remaining light liquid part were distilled at 60-65°C to obtain 9.7L of biodiesel after removing water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com