Bean dreg tempeh products and production method thereof

A technology of bean dregs tempeh and bean dregs, which is applied in the field of bean dregs tempeh and its production, can solve the problems of environmental pollution, waste, and low conversion rate, and achieve the effects of good quality, saving production time and energy consumption, and short fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

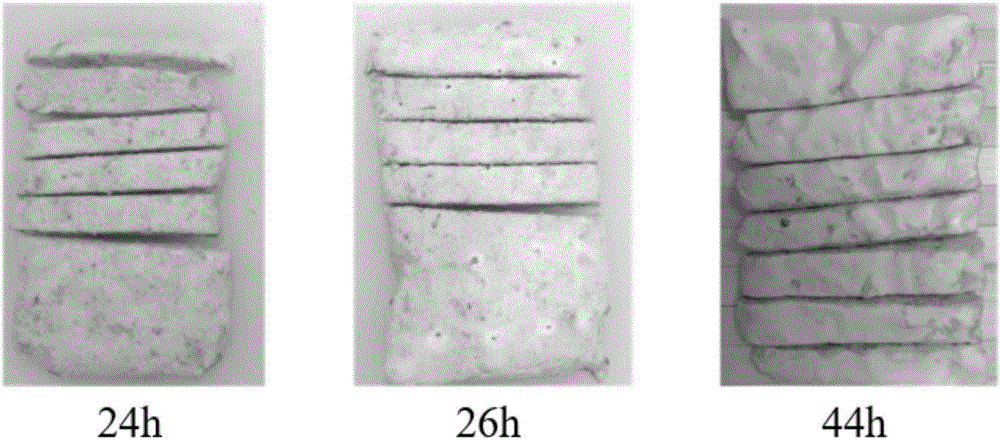

[0042] Example 1 Optimization of fermentation time of bean dregs tempeh

[0043] method:

[0044] Take 100 grams of dried bean dregs, let it cool to 38-42°C after sterilization, add the spore suspension of LT0229, about 10 5 ~10 7 spores / mL culture medium, the inoculum amount was 1%, stirred evenly, put into a No. 5 plastic bag, pierced holes, and cultivated at 30°C until hyphae appeared on the surface of bean dregs.

[0045] Fermentation was stopped at different fermentation times of the three settings, and the morphology of tempeh was observed and recorded.

[0046] Results: See Table 1

[0047] Table 1 Sensory evaluation of okara tempeh obtained at different fermentation times

[0048]

[0049] After 24 hours of bean dregs fermentation, a small amount of mycelium can be seen on the surface, but because of less mycelium, the product has poor elasticity, and the cross section is loose and not smooth;

[0050] Continue to cultivate until 26h, the growth of mycelia on t...

Embodiment 2

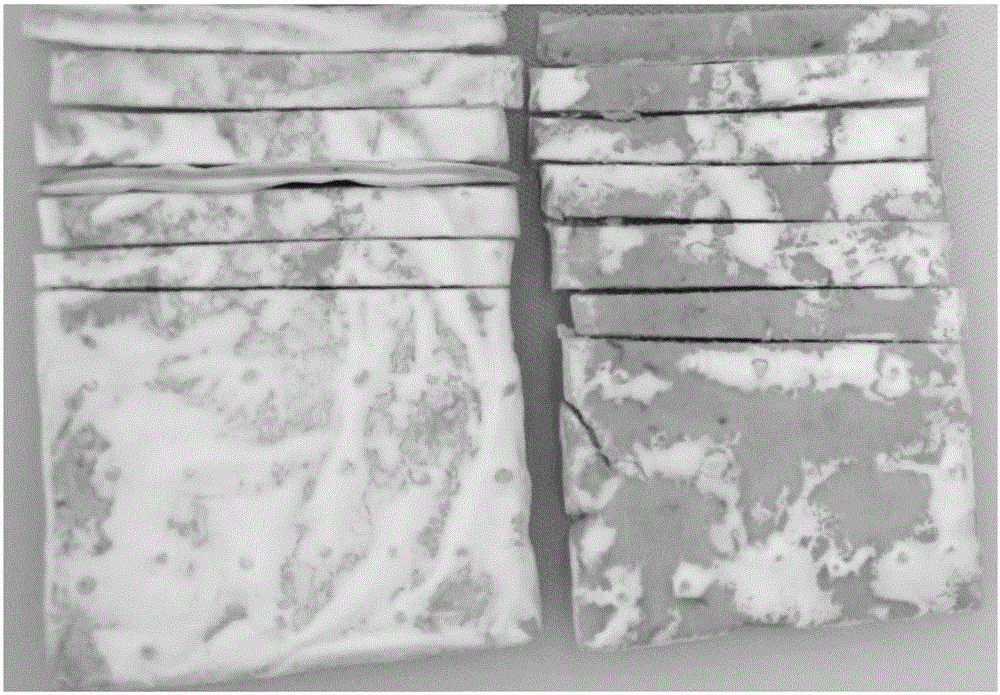

[0055] Example 2 Research on Okara Tempeh Added with Different Amounts of Starch

[0056] Taking corn starch as auxiliary material, the proportion of its addition was initially explored.

[0057] Method: Add 8g and 4g of corn starch to 100g of bean dregs, and sterilize at 121°C for 20 minutes; cool the sterilized bean dregs to 38-42°C, add the LT0229 spore suspension prepared earlier, about 10 5 ~10 7 spores / mL culture medium, the inoculum amount was 1%, after stirring evenly, put it into a No. 5 plastic bag, and pierce the holes.

[0058] Incubate at 30°C for 44 hours, and observe the morphology of tempeh products.

[0059] Results: See Table 2

[0060] Table 2 Sensory evaluation of okara tempeh with starch as auxiliary material

[0061]

[0062] Add 8g of starch to 100g of bean dregs to obtain a fermented product. A large amount of white mycelium appears on the surface and inside and is evenly distributed, with good elasticity and smooth cross-section ( figure 2 lef...

Embodiment 3

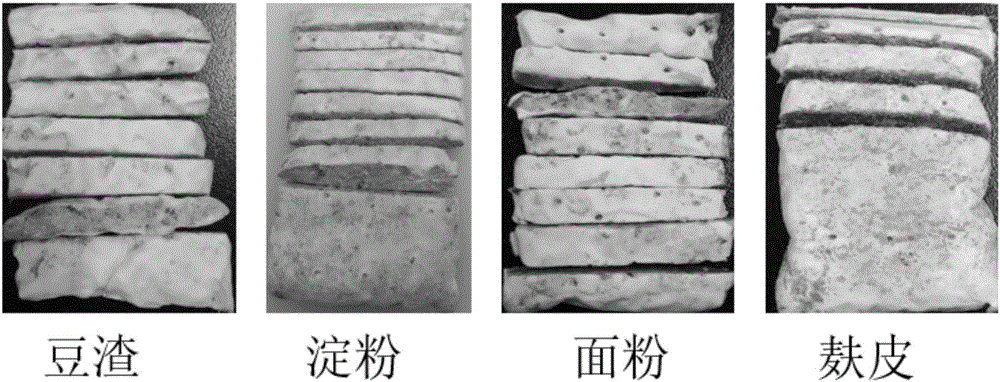

[0067] Example 3 Comparison of okara tempeh with added starch, flour and bran respectively

[0068] method:

[0069] Use starch, flour, and bran as auxiliary materials, add 8 g auxiliary materials to 100 g bean dregs, and sterilize at 121 ° C for 20 minutes; cool the sterilized bean dregs to 38 ~ 42 ° C, add LT0229 spore suspension, about 10 5 ~10 7 spores / mL culture medium, the inoculum amount was 1%, stirred evenly, put into a No. 5 plastic bag, pricked holes, cultured at 30°C for 44 hours, and observed the quality of tempeh products.

[0070] Results: See Table 3

[0071] Table 3 Sensory evaluation of okara tempeh obtained by adding different excipients

[0072]

[0073] The fermented product obtained by adding starch is covered with hyphae on the surface and inside, the product is bright yellow as a whole, has good elasticity, and the cross-section is smooth, with a slightly sour taste;

[0074] The fermented product obtained by adding flour has a large amount of wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com