Zero-formaldehyde flakeboard suitable for routing machining and preparation method of zero-formaldehyde flakeboard

A zero-formaldehyde and particleboard technology, applied in the field of zero-formaldehyde particleboard and its preparation, can solve problems such as poor internal bonding strength and waterproofness, and achieve the effect of increasing added value and superior mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

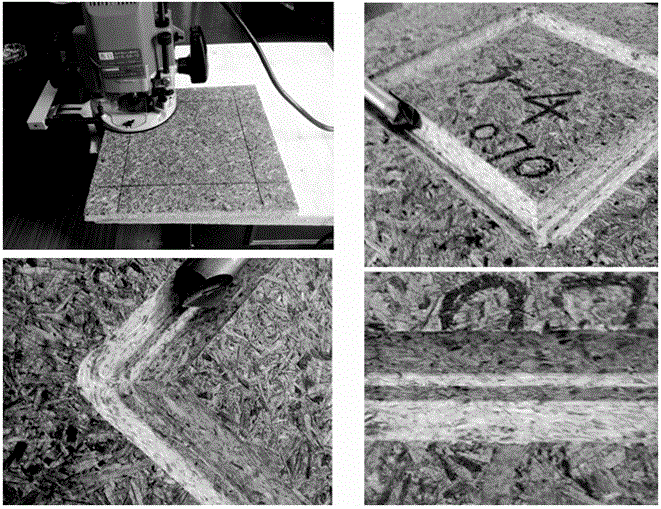

Image

Examples

preparation example Construction

[0034] The specific steps of the preparation method of the zero-formaldehyde particleboard suitable for engraving and milling processing are as follows:

[0035] 1) Treat the shavings with a surface treatment agent;

[0036] 2) Dry the shavings treated in step 1) to a moisture content of 3-12%, sizing unsaturated polyester resin, initiator, accelerator, and then add water resistance agent;

[0037] 3) The shavings obtained in step 2) are formed into billets, and hot-pressed with a continuous hot press to obtain the zero-formaldehyde particleboard suitable for engraving and milling. The hot-pressing temperature is 160-220 °C and the pressure is 2.5-20 MPa, hot pressing time is 4-30min.

[0038] In order to make the content of the present invention easier to understand, the technical solutions of the present invention will be further described below in conjunction with specific embodiments, but the present invention is not limited thereto.

Embodiment 1

[0040] 1) Treat 100 parts by weight of shavings with 1 part by weight of a surface treatment agent (prepared by mixing maleic anhydride and isocyanate at a volume ratio of 1:1);

[0041] 2) Dry the shavings treated in step 1) to a moisture content of 5%, spray 20 parts by weight of unsaturated polyester resin, 0.4 parts by weight of tert-butyl hydroperoxide, 0.2 parts by weight of cobalt cyclooctanoate, and then add 0.5 parts by weight part paraffin;

[0042] 3) The shavings obtained in step 2) were formed into billets, and hot-pressed for 7 minutes at 220 °C and 15 MPa with a continuous hot press to obtain a formaldehyde-free particle board with a thickness of 15 mm suitable for engraving and milling.

Embodiment 2

[0044] 1) Treat 100 parts by weight of shavings with 0.5 parts by weight of a surface treatment agent (prepared by mixing acetylacetone and acrylamide at a volume ratio of 3:1);

[0045]2) Dry the shavings treated in step 1) to a moisture content of 12%, spray 14 parts by weight of unsaturated polyester resin, 0.1 parts by weight of dicumyl peroxide, 0.01 parts by weight of cobalt cyclooctanoate, and then add 0.5 parts by weight of part paraffin;

[0046] 3) The shavings obtained in step 2) were formed into billets, and hot-pressed at 200 °C and 10 MPa for 4 minutes with a continuous hot press to obtain a formaldehyde-free particle board with a thickness of 12 mm and suitable for engraving and milling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com