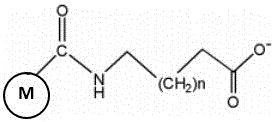

Preparation method of micron-grade superparamagnetic beads with spacer arms

A spacer arm, superparamagnetic technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of reducing the loading capacity and biological activity of biological macromolecules on the surface of magnetic beads, insufficient loading capacity, steric hindrance, etc. Achieve the effect of reducing non-specific interactions, improving activity and utilization, and expanding range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for preparing micron-scale superparamagnetic beads with spacer arms, the specific steps are as follows:

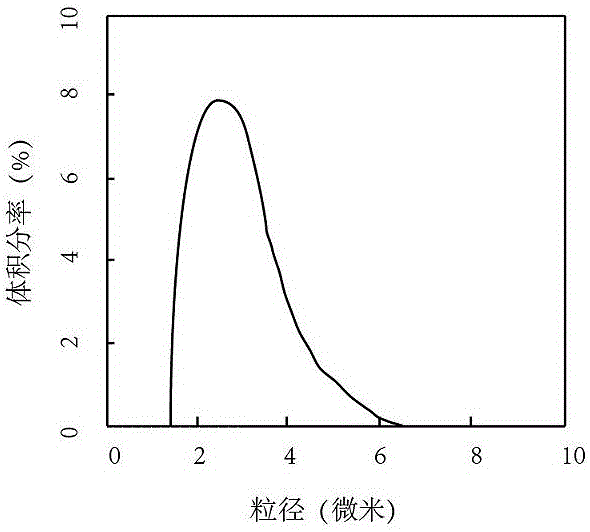

[0017] Step 1, superparamagnetic Fe 3 o 4 Preparation of Micron Magnetic Beads: Synthesis of Superparamagnetic Fe by Co-precipitation Method 3 o 4 Micron magnetic beads: FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 O was respectively dissolved in HCl solution with a concentration of 1 mol / L. The two solutions were mechanically stirred and mixed, protected by nitrogen gas, and ammonia water was added to make the pH of the solution reach 11. Stir vigorously at room temperature for 20 minutes, and use NdFe Boron magnets were used for magnetic separation, washed with high-purity water and absolute ethanol three times respectively, and vacuum-dried at 50°C for 14 hours;

[0018] Step 2, surface activation of magnetic beads: use the micron magnetic beads in step 1 to measure the hydroxyl density of the microspheres by potentiometric titration, and add 1-(3-dimethylamin...

Embodiment 2

[0021] A method for preparing micron-scale superparamagnetic beads with spacer arms, the specific steps are as follows:

[0022] Step 1, superparamagnetic Fe 3 o 4 Preparation of Micron Magnetic Beads: Synthesis of Superparamagnetic Fe by Co-precipitation Method 3 o 4 Micron magnetic beads: FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 O was respectively dissolved in HCl solution with a concentration of 1 mol / L. The two solutions were mechanically stirred and mixed, protected by nitrogen gas, and ammonia water was added to make the pH of the solution reach 11. Stir vigorously at room temperature for 25 minutes. Boron magnets were used for magnetic separation, washed with high-purity water and absolute ethanol for 4 times, and vacuum-dried at 55°C for 10 hours;

[0023] Step 2, surface activation of magnetic beads: use the micron magnetic beads in step 1 to measure the hydroxyl density of the microspheres by potentiometric titration, and add 1-(3-dimethylaminopropyl) equivalent to the...

Embodiment 3

[0026] A method for preparing micron-scale superparamagnetic beads with spacer arms, the specific steps are as follows:

[0027] Step 1, superparamagnetic Fe 3 o 4 Preparation of Micron Magnetic Beads: Synthesis of Superparamagnetic Fe by Co-precipitation Method 3 o 4 Micron magnetic beads: FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 O was respectively dissolved in HCl solution with a concentration of 1 mol / L. The two solutions were mechanically stirred and mixed, protected by nitrogen gas, and ammonia water was added to make the pH of the solution reach 11. Stir vigorously at room temperature for 30 minutes. Boron magnets are used for magnetic separation, washed with high-purity water and absolute ethanol for 5 times, and vacuum-dried at 60°C for 10-14 hours;

[0028] Step 2, surface activation of magnetic beads: use the micron magnetic beads in step 1 to measure the hydroxyl density of the microspheres by potentiometric titration, and add 1-(3-dimethylaminopropyl) equivalent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com