Method for treating refined sugar ion-exchange waste liquid

A technology of refined sugar and separation, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., to achieve the effects of reducing wastewater treatment pressure, saving costs, and good treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

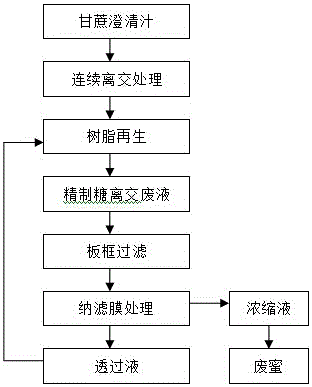

Image

Examples

Embodiment 1

[0024] A method for treating refined sugar separation waste liquid, which is to filter the refined sugar separation waste liquid through a plate and frame filter to remove suspended impurities, and then enter the filtrate into a nanofiltration device for treatment to obtain a permeate and a concentrate; the obtained permeate The superfluid can directly elute and regenerate the ion exchange resin used for the decolorization of refined sugar.

[0025] The pH of the purified sugar separation waste liquid is 11.8;

[0026] The nanofiltration membrane in the nanofiltration device is hydrophilic, and the material of the nanofiltration membrane is polyamide; the nanofiltration membrane adopts 1812 roll-type membrane modules; the molecular weight cut-off of the nanofiltration membrane is greater than 300Da and less than 800Da;

[0027] The maximum operating pressure of the nanofiltration device is 2.0MPa.

[0028] The temperature of the refined sugar separation waste liquid is 20°C. ...

Embodiment 2

[0030] A method for treating refined sugar separation waste liquid, which is to filter the refined sugar separation waste liquid through a plate and frame filter to remove suspended impurities, and then enter the filtrate into a nanofiltration device for treatment to obtain a permeate and a concentrate; the obtained permeate The superfluid can directly elute and regenerate the ion exchange resin used for the decolorization of refined sugar.

[0031] The pH of the purified sugar ionization waste liquid is >11, and the pH is ≤12.

[0032] The nanofiltration membrane in the nanofiltration device is hydrophilic, and the material of the nanofiltration membrane is polyamide; the nanofiltration membrane adopts 1812 roll-type membrane modules; the molecular weight cut-off of the nanofiltration membrane is greater than 300Da and less than 800Da;

[0033] The maximum operating pressure of the nanofiltration device is 3.0MPa.

[0034] The temperature of the refined sugar separation wast...

Embodiment 3

[0036] A method for treating refined sugar separation waste liquid, which is to filter the refined sugar separation waste liquid through a plate and frame filter to remove suspended impurities, and then enter the filtrate into a nanofiltration device for treatment to obtain a permeate and a concentrate; the obtained permeate The superfluid can directly elute and regenerate the ion exchange resin used for the decolorization of refined sugar.

[0037] The pH of the purified sugar separation waste liquid is >11;

[0038] The nanofiltration membrane in the nanofiltration device is hydrophilic, and the material of the nanofiltration membrane is polyamide; the nanofiltration membrane adopts 1812 roll-type membrane modules; the molecular weight cut-off of the nanofiltration membrane is greater than 300Da and less than 800Da;

[0039] The maximum operating pressure of the nanofiltration device is 2.5MPa.

[0040] The temperature of the refined sugar separation waste liquid is 30°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com