Advanced treatment and decoloration method for printing and dyeing wastewater

A printing and dyeing wastewater and advanced treatment technology, applied in the field of water treatment, can solve the problems of substandard effluent water quality, achieve the effect of increasing the reaction rate and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

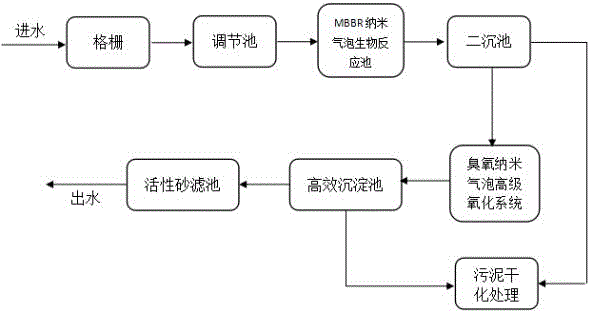

[0034] refer to figure 1 As shown, a printing and dyeing wastewater advanced treatment and decolorization method, comprising the following steps:

[0035] Step 1) Pass the printing and dyeing wastewater to be treated through the grid to filter out large impurities;

[0036] Step 2) Send the filtered printing and dyeing wastewater into the adjustment tank for equalization and adjustment treatment;

[0037] Step 3) Send the printing and dyeing wastewater in the regulating tank to the MBBR nano-bubble biological reaction tank for biochemical reaction, ammonification reaction and nitrification reaction to reduce CODcr, NH 4 -N, TP, concentration of odorous substances and reduction of water color and turbidity;

[0038] A certain amount of MBBR biofilm fillers with high specific surface area suitable for the attachment and reproduction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com